Home > Products > milling cutter > Introduction to milling tool and their application

Introduction to milling tool and their application

- zhengzhou

- T/T PayPal

- 10 days

You May Like

Product Details

| Brand Name | MoreSuperHard | Place of Origin | China | |

| Model Number | various | Size | customized | |

| Type | Other, cutting tool |

Product Description

End mills

End mills are the most common milling cutters. End mills are available in a wide variety of lengths, diameters, and types. A square end mill is used for most general milling applications. It produces a sharp edge at the bottom of pockets and slots.

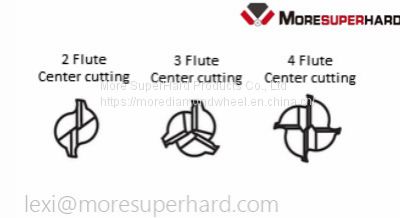

End mills can be center cutting and non-center cutting. As their name implies, center cutting end mills have cutting edges on both the end face of the cutter and the sides. Center cutting end mills are essential for plunge milling.

Non-center cutting end mills have cutting edges only on the sides and are used only for side milling. These tools are identified by a small hole at the center.

Roughing end mills have serrations in the teeth to quickly remove large amounts of material without creating vibration. The serrations produce many small chips and a rough finish.

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing applications.

Flutes

Spiral-shaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket. The most common options are 2, 3, or 4 flutes. The more flutes, the more cutting edges but the narrower the channel for chip evacuation.

An important consideration when choosing the number of flutes is called “chip load”. “Chip load” is a measurement of the thickness of material removed by each cutting edge during a cut.

The number of flutes you choose depends on the material you want to cut and the capabilities of your machine. A material like aluminum produces large chips compared to other materials. For that reason, 4 flute end mills are rarely used with aluminum because the flutes can get jammed with chips and break the cutter. For harder materials, you want to use more flutes. Having more flutes reduces chip load and improves surface finish. While the number, direction and type of flutes that a cutting tool has can vary widely, the tools most commonly used have two flutes and are up-cut spirals to move the chips up out of the cut.

· Two Flute: Has the greatest amount of flute space, allowing for more chip carrying capacity in softer materials. Used primarily in slotting and pocketing of non-ferrous materials like aluminum where chip removal is a concern.

· Three Flute: Allows for better part finish in harder materials. The three flutes provide for greater strength and the ability to pocket and slot both ferrous and non-ferrous materials.

· Four Flute/Multiple Flute: Ideal for finish milling. The extra flutes allow for faster feed rates to produce a much finer finish than two or three flute tools. However, the reduced flute space may cause problems with chip removal.

The most common flute numbers for general milling operations are two (better space for chip ejection) and four (better surface finish).

Applications for End Mills

Side Milling

| Face Milling

| Slot Milling

| Plunge Milling | Ramping

|

Machining of an edge surface on the part. | Machining of a top face on the part.

| Machining between two edge surfaces. | Axial feeding into a part along the Z axis. Requires a center cutting end mill. | Axial feeding into a part along the Z axis as well as X or Y. Requires a center cutting end mill. |

Contact Us

- More SuperHard Products Co., Ltd

Product Categories

New Products

-

disadvantages of coated tools

-

tools used for turning

-

the case of CBN cutter processing nozzle

-

CBN tool material, mark and application

-

PCD sintering drilling bit for CFRP/GFRP

-

grooving milling cutter series

-

CBN standard cutting tools, CBN inserts

-

monocrystal diamond tools

-

PCD slotting mill cutter

-

PCD ball end mill for processing spindle hole

-

PCD reamer profile tool series

-

PCD reamer for camshaft bore

Popular Searches

- cutting tool

- carbide tool

- carbide insert

- carbide

- cast iron

- machine tool

- drill bits

- Tile Cutter

- end mill

- carbide cutter

- Milling Tool

- End Mill Cutter

- End Milling Cutter

- Cnc Milling Cutter

- Face Milling Cutter

- router bit

- carbide milling cutter

- carbide end mill

- solid carbide

- solid carbide end mill

- Corner Radius Milling Cutter

- Milling Tool Cutter

- Drill Cutter

- Carbide End Mill Cutter

- Milling Inserts Cutter

- cutting tool

- tungsten carbide

- carbide tool

- cemented carbide

- milling machine

Recommended Products

- Premium 40/60mm Diamond Grinding Cup Wheel for Angle Grinders Use

- 4" Diamond Grinding Cup Wheel Aluminum Based Turbo Abrasive Tools for Concrete

- 100mm Resin Filled Diamond Turbo Cup Wheels Aluminum Backer for Grinding Concrete

- 35mm Vacuum Brazed Dry Diamond Core Drill Bits for Drilling Stone

- Diamond Turbo Line-up Type 50mm Stone Dry Core Drill Bit Arbor 5/8"-11

- Dry 1/4 Inch Diamond Core Drill Bit 6mm for Milling Stone

- Diameter 25mm Wet Drilling Core Bit for Stone Marble Granite Ceramic Tile

- High-Performance 18mm Dry Diamond Core Drill for Stonework

- Premium 1-1/2 Inch Diamond Core Drill Bits for Dry Granite Drilling

- Premium 8mm Diamond Dry Core Drill Bits for Stone Milling

- High-Performance 35mm M14 Diamond Wet Core Drill Bits for Tile and Porcelain

- Diamond 1-1/4 Inch Dry Drill Bits for Masonry, Granite, Stone

Find Similar Products By Category

- Tools & Hardware > Abrasive & Grinding > Grinding Wheel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile