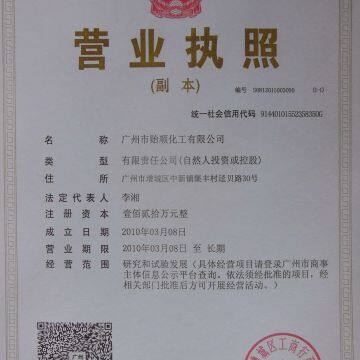

- Guangzhou Yishun chemical co., Ltd

-

Guangzhou, Guangdong, China

- Main products: powerful degreasing agent , Environmental protection deplating agent , Oxidized chemicals, Industrial cleaning agent , Electroplating auxiliaries, chemical plating agent, Phosphate Coating Chemicals, Rust Protection Chemicals, Cutting Fluid, Daily Chemicals, Custom Chemical Services, Chemical Reagents

Home > Products > Chemical plating solution series > Nickel plating Chemical plating bright nickel Brushed nickel agent

Nickel plating Chemical plating bright nickel Brushed nickel agent

- Guangzhou

- T/T L/C D/P D/A Credit Card PayPal Other Cash

- 1 days

You May Like

-

Chemical black nickel Black nickel plating Black nickel plating process

-

Magnesium alloy electroless plating Rolled bright nickel High bright electroless nickel plating

-

Nickel plating anti-oxidation Electroless nickel plating Spray-plated chemical nickel plating liquid

-

Chemical sink nickel syrup Ceramic electroless plating Nickel plated sealer

-

Nickel plating solution Chemical nickel liquid Graphite powder nickel plating solution

-

Plating nickel alloy Stainless steel electroless nickel plating Chemical immersion plating

Product Details

| Brand Name | YiShun | Place of Origin | China | |

| Model Number | Q/YS.602-4 | Type | Other, metal surface treatment agent | |

| Purity | 99.9% | EINECS No. | 1 | |

| MF | 1 | Other Names | Environmentally friendly type chemical the matte nickel plating liquid | |

| CAS No. | 1 | Usage | Other, Coating Auxiliary Agents, Surfactants, Water Treatment Chemicals, metal surface treatment agent |

Product Description

Environmentally friendly type chemical the matte nickel plating liquid

First, the product code: Q / YS.602-4 (Yi Shun brand)

Second, product features:

The chemical nickel plating liquid is suitable for iron, steel, zinc alloy, zinc-treated aluminum alloy and copper alloy plated matt nickel alloy layer. This product is non-toxic, environmentally friendly. No plating equipment, just thermostat device. Plating is matte nickel-phosphorus alloy layer, excellent corrosion resistance, excellent bonding. Strong bath stability, life expectancy more than 12 cycles. This product is not only suitable for nickel plated metal surface (such as: iron, stainless steel, aluminum, copper, etc.), the same applies to non-metallic nickel plating, and does not require expensive palladium low cost. For example: ceramic nickel, glass nickel, diamond nickel, carbon nickel, plastic nickel, resin nickel and so on. Bath maintenance is simple, low cost, does not require plating equipment. (Note: 7% -11% phosphorus content)

Third, the product composition:

Products are make up of A agent, B agent and C three agents, A and B ratio of 1: 2 open cylinder, with A and C ratio of 1: 1 added as an intermediate supplement.

Fourth, open cylinder preparation and use of agents:

① A and B agent with water with the match, with the ratio of A: B: water = 1: 2: 7.

② with pure water to clean the plating tank, and then added to the tank half the size of pure water tank.

③ first B agent proportionally added to the tank stir, while stirring slowly add A agent.

④ stir the bath after the test PH value, with 10% ammonia to adjust the PH value to 4.7 ± 0.2.

⑤ add deionized water to the specified volume.

⑥ heating bath bath temperature stable at 90 ℃ ± 3 ℃.

Fifth, the operation process:

① pre-treatment: Pre-treatment of the coating quality is essential, to make the surface of the workpiece before plating no pollution, and is in an activated state, this process are: degreasing, rust, polishing, washing.

② pickling activation: pickling activator soak the workpiece with 2-3 minutes, and then washed.

③ rinse the workpiece with hot deionized water, the workpiece temperature, in order to avoid the next plating, the cold workpiece cooling bath to absorb heat and lead to stop plating.

④ in accordance with the loading ratio 0.5-1.5 d㎡ / L hanging suspension in the bath, the control bath temperature at 90 ℃ ± 3 ℃, the use of time> 5 minutes, depending on the thickness of the plating process, there must be Slight mechanical stirring.

⑤ plating process should be mild light mixing, the temperature and bath evenly distributed, so as to ensure the stability of chemical nickel plating, and coating consistency. At the same time, the bath should be cyclically filtered. Filter: aperture 1-8 microns, resistant to 100 degrees Celsius, acid.

⑥ nickel plated with hot water to be completed, if necessary, can be passivated.

Sixth, the maintenance of chemical nickel plating:

① in the plating process, because of the constant consumption of ingredients, plating speed will slow down, according to the number of bubbles to add supplements A and C, according to A: C = 1: 1 added. To supplement a small amount of times. Each consumption of one gram of nickel metal, need to add A and C each 10 ml. When a large number of replenishments A and C, the first cold plating, then add A, C supplements, and stir, in order to carry out nickel plating.

② plating process, the plating solution pH value will change, fresh plating solution PH control in 4.7-4.8, with the plating solution aging, PH value will slowly rise.

③ for copper and its alloy surface nickel to use clean wire or aluminum wire and copper workpiece contact plating.

④ plating process to the bath often analysis test: PH value and nickel ion content.

Nickel detection method: Take 5.00ml plating solution into a 500ml flask, add 100ml of deionized water, then add 100ml of ammonia, add carbamate indicator. With 0.05mol / L of EDTA titration from orange to purple as the end point, the volume of milliliters consumed EDTA is recorded as V.

Formula: Nickel (g / L) = 0.587 * V

⑤ pre-chemical nickel plating to undergo rigorous pre-treatment, to ensure that the workpiece surface is clean and activated.

⑥ often inspect the equipment: automatic temperature control system, circulating filtration system, timely detection and timely exclusion.

⑦ bath loading ratio to be controlled at 0.5d㎡ -1.5d㎡.

Our services

Order Guangzhou YiShun Chemical Company's products, you will have the following technical support: 1, selection of professional engineers. 2, phone detailed understanding.3, video demo. 4, live demonstrations. 5, site service.6, special technology R & D and preparation. 7, continue to follow the sale.

Contact Us

- Guangzhou Yishun chemical co., Ltd

- Contact nameLinda Chat Now

- Phone86-020-87471488

- Addresszengcheng, Guangzhou, Guangdong

Product Categories

New Products

-

Cyanide-free silver plating solution Silver-plated copper wire Copper-plated jewelry

-

Silver plating protection solution Acid-free cyanide silver plating Silver plating agent

-

Plated matt silver liquid Metal plated matt silver Copper surface chemical plating matte silver

-

Rolled gold plating manufacturers Ceramic gold plated gold Buddha plated gold

-

Metal jewelry gold plated Gold plating manufacturers Brass gold plated liquid

-

Metal color retention agent Aluminum imitation liquid Imitation gold liquid

-

Stainless steel plated rose gold Gold coloring agent Metal imitation gold agent

-

Plating liquid Plating protection solution Environmental metal plating

-

Stainless steel surface electrolytic polishing Stainless steel electrolytic polishing solution

-

Cyanide-free nickel reductant Import nickel withdrawal agent Environmental protection chemical nickel remover

-

Stainless steel copper plating Stainless steel without electrolytic liquid copper plating

-

Pure copper plating Chemical precipitated copper agent Door flower copper plating

-

Bright tin plating process Copper plating process Copper tin plating

-

Nickel plating on copper Copper plated with nickel Iron chemical nickel plating

-

Parts nickel plating brightener High-phosphorus chemical nickel High-phosphorus chemical nickel plating liquid

-

Chemical nickel phosphorus plating Low-phosphorus chemical nickel Chemical plating low phosphorus nickel liquid

-

Black nickel plated surface Brass plated black nickel Black nickel special nickel plating liquid

-

Nickel plated aqueous sealer Hardware nickel plating brightener Electronic ceramic special chemical nickel plating

-

Nickel-plated anti-tarnish Nickel plating protective agent Diamond surface electroless plating

-

Pure copper electroless silver plating Silver plated copper wire Oxygen-free copper plated silver

-

Silver plated gold Aluminum plated gold Faucet gold plating

-

Stainless steel surface electrolytic polishing Stainless steel mirror electrolytic polishing

-

Nickel stripping agent Chemical nickel deplating process Nickel removal liquid

-

Tin surface protection agent Tin-plated copper potion Anti-oxidation tin plating agent

Popular Searches

Recommended Products

- ferric phosphate anhydrous

- iron iii oxide hydroxide battery material for Lithium Iron Phosphate

- iron-chromium liquid flow battery electrolyte

- ferrous chromium chloride for lithium iron phosphate battery

- compound ferrous chromium chloride solid cathode material of lithium iron phosphate battery

- High-quality Dimethyl Silicone Oil PDMS 500cst

- PU Water Based Mold Release Agent

- Food & Medical Grade Liquid Silicone Rubber Mold Translucent

- Transparent Liquid Silicone Rubber For Foot Care Products

- PDMS 350cst High-quality Dimethyl Silicone Oil

- CAS 497-19-8 Sodium Carbonate Na2CO3 China Factory Manufacturer Industrial Grade Soda Ash

- Key Additive to Enhance Detergent Quality — Fast-Dispersing, High-Clarity HPMC Solution

Find Similar Products By Category

- Chemicals > Chemical Auxiliary & Catalyst > Chemical Auxiliary

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Linda

Hi there! Welcome to my shop. Let me know if you have any questions.

Linda

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile