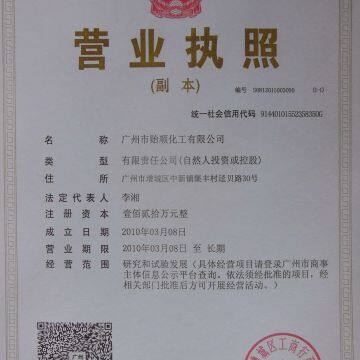

- Guangzhou Yishun chemical co., Ltd

-

Guangzhou, Guangdong, China

- Main products: powerful degreasing agent , Environmental protection deplating agent , Oxidized chemicals, Industrial cleaning agent , Electroplating auxiliaries, chemical plating agent, Phosphate Coating Chemicals, Rust Protection Chemicals, Cutting Fluid, Daily Chemicals, Custom Chemical Services, Chemical Reagents

Home > Products > copper processing series > Film removal agent Membrance removal agent Film stripping agent

Film removal agent Membrance removal agent Film stripping agent

- Guangzhou

- T/T L/C D/P D/A Credit Card PayPal Other Cash

- 1 days

You May Like

-

Environmental copper matte agent Metal matte agent Electroless matte for copper

-

The poor quality brass and bronze chemical polishing agent Metal polishing agent Electroless polishing process

-

Poor quality brass environmental chemical polishing agents metal polishing agents Electroless polishing process

-

Copper alloy deburring polishing agent Metal burrs removal Deburring polishing for coper

-

Universal type copper blackening agent Metal blackening agent Electroless blackening process for copper

-

Copper polishing agent Metal polishing paste Electroless polishing process for coper

Product Details

| Type | Oxidizing Chemicals |

Product Description

Environmental copper polishing agent

First, the product code: Q / YS.106 (Yi-shun brand)

Second, product introduction:

This product is suitable for polished copper products. Do not need machinery and equipment processing, direct soaking method can be. No smoke, no smell. Does not contain any toxic and hazardous substances, is a very environmentally friendly chemical polishing products. Polished copper workpiece mirror effect. Provincial Labor Provincial equipment saves costs, can replace and surpass traditional mechanical polishing. Mechanical polishing can not be thrown to the dead, the use of chemical polishing can be solved.

Third, the use of methods:

1.The product consists of a mixture of A and B agents.

2.The operation process is as follows:

1) copper parts degreasing, in addition to dirt.

2) with tap water to clean the residual copper parts of the oil potion rinse.

3) press A agent: B agent: water to 4: 1: 3 with the polishing agent syrup. Stir, at the same time, the match after the medicine placed in a cold water bath at a temperature of 30 ℃ for cooling and heat treatment. Cooling water bath method of treatment, if conditions can also use ice to cool.

4)After degreasing descaling copper parts into plastic baskets. When loading the best erection of copper parts placed one-time do not put too much work-pieces, so as not to sharp heating.

5) copper basket will be installed in a good copper casting agent soaked in a good solution, while turning the workpiece, the workpiece polished evenly. About 2-4 minutes after the copper workpiece was uniform bright black.

6)remove the copper parts, promptly cleaned in water again. Then immediately into the addition to the film in addition to film. (In addition to film 6-8 times the use of water) In addition to film time is about 8-18 seconds. In addition to the film to jitter plastic basket so that the membrane thoroughly. Especially pipe-shaped copper parts. The interior of the tube must be completely clean. After the removal of the workpiece revealed a very bright mirror effect.

7) timely self-use water fully rinse.

8) final passivation solution with copper color retention treatment.

Fourth, note:

1.The workpiece before polishing can not have oil and dirt and ink words and so on.

2.Syrup on the skin irritating and corrosive, please do not contact with the skin. Wear plastic gloves operation.

3.This product is prohibited in the course of contact with iron, nickel, stainless steel, manganese and other metals, or reduce the service life of the product.

4. In the polishing process of the workpiece is best to cool the bath cooling measures. Polishing liquid temperature control at 40 ℃ ± 5 ℃, do not exceed 50 ℃, and one-time do not put too much workpieces, so as not to sharp heating. When conditions permit, can be put into ice cubes to cool down. If the polishing effect is not good, such as copper surface red rose yellow, should pay attention to whether the temperature of 45 ℃, or should be promptly added A and B.

5.When loading the workpiece to be staggered placed, the best distance between the workpiece. Can make the workpiece erected hanging in the polishing liquid without overlapping with other parts and collision is the best, or need to flip the workpiece in time in order to polish evenly.

6.The case of pipeline operations, the best way to hang copper parts.

7.There will be loss of ingredients in the polishing process, in order to maintain the performance of the polishing liquid for a long time, 1-2 polishing products should be added with 2% -3% polishing liquid after each polishing, and stir well. Do not add water during polishing stock solution. use.

8.This product can not be exposed. Store in the shade.

Fifth, waste disposal methods:

1. Dilute the waste with 10x water and neutralize to pH 8-9 with lime or caustic soda to filter the precipitate.

2.The filtrate placed in the sewage tank by the degradation of microorganisms in nature can be directly discharged. This product is 100% biodegradable in four days.

Sixth, safe operation matters:

1.The product stored in the open cement floor or sand ground, is strictly prohibited exposure and high temperature.

2.This product is strictly prohibited with iron, metal powder, cardboard, fiber and flammable organic matter stored together. It is also strictly prohibited to be stored together with sodium hydroxide (potassium) and other chemicals and chemicals.

Our services

Order Guangzhou YiShun Chemical Company's products, you will have the following technical support: 1, selection of professional engineers. 2, phone detailed understanding.3, video demo. 4, live demonstrations. 5, site service.6, special technology R & D and preparation. 7, continue to follow the sale.

Contact Us

- Guangzhou Yishun chemical co., Ltd

- Contact nameLinda Chat Now

- Phone86-020-87471488

- Addresszengcheng, Guangzhou, Guangdong

Product Categories

New Products

-

Spraying type copper polishing agent Chemical polishing agent Electroless polishing process for copper

-

Brass coloring red bronze agents Chemical coloring agent Brass coloring agent

-

Metal copper coloring agent Copper malachite green colorant Copper coloring agent

-

Metal coper etching agent Copper etching solution Alkaline etching agent

-

Copper matte agents Copper surface matte treatment agents Copper electroless matte agent

-

Metal rust removal brightening agent Copper degreasing and remove rust agent Copper cleaning agent

-

Copper degreasing passivation agent Oil removal and antioxidants Copper cleaning agent

-

Copper phosphor bronze for blackening agent Copper blackening agent Copper electroless blackening process

-

Tin phosphorus bronze special polishing agent metal brightening agent

-

Copper normal temperature blackening agent Copper alloy normal temperature blackening Copper electroless polishing

-

Environmentally friendly copper chemical polishing paste Metal polishing agents Copper electroless polishing process

-

Aluminum brass special chemical polishing agent Aluminum brass brightening agent Aluminum brass electroless polishing

-

Metal coloring agents Copper coloring agent Copper coloring chocolate

-

Metal blackening agent Tin copper components room temperature blackening agent Tin alloy electroless blackening

-

Metal coloring agents The variegated copperware to show spot agent

-

Metal polishing agents Chrome bronze chemical polishing agent Electroless polishing process

-

Metal cleaning agents Brass whitening agent Brass whitener

-

Metal passivation agents Aluminum chromium-free passivation solution Aluminum chemical additives

-

Die-cast aluminum passivation solution Aluminum oxidation Chemical additives

-

Aluminum matte degreasing two in one Metal degreasing agents Aluminum cleaning agent

-

Metal polishing agents Aluminum chemical polishing agent Aluminum electroless polishing process

-

Metal polishing agents Aluminum chemical deburring polishing agent

-

Metal passivation agents Die-cast aluminum imitation gold passivation agent

-

Metal brightening agents Cast aluminum brightening agent Cast aluminum polishing agent

Popular Searches

- sodium hypochlorite

- naclo

- hypochlorite

- calcium hypochlorite

- calcium salt

- potassium butyl xanthate

- calcium sodium

- sodium hypochlorite production

- sodium process

- granule sodium

- sodium hypochlorite water

- sodium 80% powder

- lime plastering

- sodium hypochlorite disinfection

- hypochlorite sodium

- sodium granular powder

- hypochlorite production

- electrolysis sodium hypochlorite

- swimming pool salt

- sea fish aquarium

- of calcium powder

- quotation sample

- aquarium coral

- emamectin benzoate wdg

- calcium price powder

- ptf

- aqua clear

- aquarium for sea water

- aquarium jellyfish

- aquarium white coral

Recommended Products

- Sodium Molybdate Export-HOOCHEMTEC

- PAPP Sodium Metasilicate Pentahydrate Factory Price cas 66034-17-1

- Sodium Metasilicate Granular in detergent industrial

- STPP Sodium Metasilicate Granular in detergent industrial SMS-5H2O

- Cocamido Propyl Betaine 35% stability Factory Price

- Potato Dextrose Agar

- MacC /MacConkey Agar

- EMB Agar

- Tryptose

- Lecithin from egg yolk CAS:93685-90-6

- HSPC CAS:92128-87-5

- Casein acid CAS:65072-00-6

Find Similar Products By Category

- Chemicals > Chemical Reagent

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Linda

Hi there! Welcome to my shop. Let me know if you have any questions.

Linda

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile