Home > Products > Rotary Kiln Equipment > kaolin powder rotary kiln of kaolinite rotary kiln for kaolin clay calcined

kaolin powder rotary kiln of kaolinite rotary kiln for kaolin clay calcined

- Qingdao Shanghai Tianjin Lianyungang

- T/T Credit Card

You May Like

Product Details

| Condition | New | Production Capacity | 1.2-1.9t/h | |

| Place of Origin | Henan, China | Brand Name | Derui | |

| Model Number | Y-1633 | Voltage | 220v/380v | |

| Power(W) | 22kw | Dimension(L*W*H) | 1.6*33m | |

| Weight | 50t | Certification | ISO | |

| Warranty | one year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

kaolin powder rotary kiln of kaolinite rotary kiln for kaolin clay calcined

Kaolinite introduction:

Kaolinite is a clay mineral, part of the group of industrial minerals, with the chemical composition Al2Si2O5(OH)4. It is a layered silicate mineral, with one tetrahedral sheet linked through oxygen atoms to one octahedral sheet of alumina octahedra.Rocks that are rich in kaolinite are known as kaolin or china clay.

Introduction of kaolinite rotary kiln:

Kaolinite rotary kiln is the main equipment of cement clinker dry -process and wet -process production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc.

The kaolinite rotary kiln consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc.

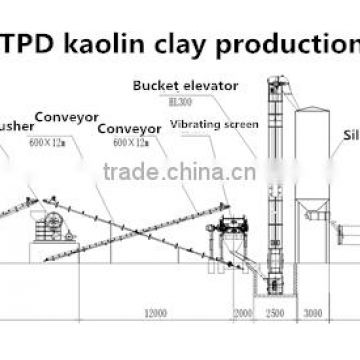

Kaolin clay production line:

Feeder------Jaw crusher------conveyor------fine crusher------conveyor------vibrating screen------bucket elevator------silo------Rotary kiln------cooling pool------conveyor

Kaolinite rotary kiln working process:

Step 1: Raw material

In the procurement process of raw materials, It has great superiority in rich raw materials and convenient transportation, tested the samples of material regularly from prospecting to inspection and application.

It controls the procurement process strictly for the stability of production.

Step 2: Making powder

In the milling process, It adopts the advanced domestic ball grinder auxiliary with raymond mill for milling powder, controls the granularity of milling powder strictly from 350M to 400M. The crude ore has been crushed in each class and batched respectively. It inspects the granularity of milling powder strictly for its quality.

Step 3: Mixing powder

In the mixing process, charging mixture by computer, weighing in electronic scales, mixture ratio is exactly same with required. Controlling the mixing time reasonably from 20 to 30 minutes for the mixing unifity of materials.

Step 4: Making pelletization

In the pelletization process, It adopts the ø1.5 Rotary-type granulator. The workmen has been trained strictly before go on duty. The technics is spraying pelletization. The time of pelletization is 50-70 minutes, making sure the particle within the size range of technical requirement.

Step 5: Drying and sieving

In the drying process, The tube-type drying kiln controls the humidity of semi-finished products ,drying and dedusting, to be the perfect state for sieving. In the sieving process, The combined type drum sieve which was invented by our company can make sieving in multilayers, inspection several times. All of the particles will be controled by the first and second screen of the combined type drum sieve to tally with the size range.

Step 6: Sintering

In the sintering process, Different products adopts different technics. general products is sintered by natural gas in the rotary kiln, The automation cooling, smashing, dedusting, sieving, packing and deliverd to the storehouse.

Step 7: Classification

After sintered the product is cooled, smashed, dedusted, sieved and packed,delivered to storehouse.

Step 8: Warehouse

In the storage processs, According to the standard of oil industry, enforcing the principles of class-based Storage ,damp proof and dedusting.

kaolinite rotary kiln techcical parameter:

Kaolin clay application:

Finely grained kaolin is also used in top quality porcelain, bone china and as a bonding agent in making paper. Premium white

china clay is low in contaminants and iron. This clay is able to balance the skin’s sebum activity. For those unfamiliar with

clay masks, this is the one that’s recommended the most. White kaolin is also suitable for children and adults with sensitive

skin.

Kaolinite rotary kiln shipping:

Derui Introduction:

Gongyi Derui Machinery Co., Ltd is located in Zhengzhou, Henan, China(mainland).Our main product include: rotary kiln, stone crusher, ball mill, mineral ore dressing equipment, dryer plant, grinding equipment, etc.

Rotary kiln equipment include:Active lime rotary kiln, ceramsite sand rotary kiln, kaolinite rotary kiln, cement rotary kiln, iron ore rotary kiln, Magnesite rotary kiln, etc.

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Contact Us

- Gongyi Derui Machinery Co., Ltd.

- Contact nameLisa liu Chat Now

- Phone0086-371-64319887

- AddressMiddle of Heluo Road, Gongyi, Henan, China(Mainland), Zhengzhou, Henan

Product Categories

New Products

-

Iron ore reduction machine manufacturer

-

Lime manufacturing machine of limestone rotary kiln price in China

-

Iron ore roasting kiln of iron oxide rotary kiln price in China

-

LECA Lightweight Expanded Clay Aggregate Rotary Kiln

-

Widely Used LECA Rotary Kiln with Energy Saving

-

China Low Price Lab Test Rotary Kiln

-

Hot Selling High Efficient Durable Kaolin and Metakaolin Rotary Kiln

-

2.5x40m Metallurgy Ilmenite Rotary Kiln Made in China

-

Reasonable Design Gypsum Calcining Rotary Kiln with Simple Structure

-

2017 China Energy Saving Metallurgy Gypsum Rotary Kiln

-

Low Consumption and High Efficient Dry Process Rotary Kiln for Calcined Dolomite

-

Widely Applied Dolomite Rotary Kiln for Sales

-

ISO9001&CE Certificate Durable Dolomite Calcination Rotary Kiln

-

Professional Energy Saving Dolomite Calcination Machine Rotary Kiln for Sale

-

Energy-Saving Chemical Industry Clay Ceramsite Calcination Equipment Rotary Kiln with Large Capacity

-

Hot Selling High Efficient Durable Clay Ceramsite Production Proces Rotary Kiln

-

Mining Industry Calcination Equipment Rotary Kiln With ISO and CE Inspection

-

Limestone calcination equipment, limestone roary kiln, lime production machine

-

Durable Ceramsite Sand Rotary Kiln with ISO CE Approved

-

EAF dust and zinc ore calcination machine of zinc oxide equipment price in China

-

Widely Used Ceramic Proppant Rotary Kiln Made In China

-

Low Cost Ceramic Sand Rotary Kiln in Hot Selling France

-

Low Energy Consumption Chemical Alumina Rotary Kiln with CE ISO SGS

-

Chemicals Rotary Kiln Rotary Furnace Kiln in Metallurgy Chemical Building

Popular Searches

- concrete truck

- active lime kiln

- lime kiln equipment

- industrial lime kiln

- shaft lime kiln

- vertical lime kiln

- rotary kiln

- cement grinding station

- mixer truck

- Concrete Mixer Truck

- Rotary Kiln Machine

- lime kiln

- kiln

- Lime Rotary Kiln

- Vertical Shaft Lime Kiln

- rotary kiln activated carbon

- cement kiln

- Cement Mixer Truck

- Mixer Tank Truck

- Mixer Machine Truck

- concrete mixer truck weight

- Concrete Mixer Car

- Vertical Shaft Kiln

- Quicklime Production Line

- Quicklime Rotary Kiln

- transit mixer

- mixer vehicle

- Clinker Grinding Plant

- cement truck

- wall paint spray gun

Recommended Products

- Water conservancy engineering mixing rod, concrete vibrator, excavator used

- Construction machinery concrete mixer hydraulic vibrator

- Engineering excavator modified vibrating rod concrete vibrating machine

- Concrete vibrating machine excavator modified vibrating rod

- Vibration compaction machine excavator modification z'd'qi

- Construction of concrete mixer, mechanical sliding mixing bucket

- Slip front mixer forklift modification mixing bucket discount

- Slip front mixer forklift modification mixing bucket discount

- Small shovel to mixer head loader hydraulic mixing bucket manufacturer

- Loader modification, mixing bucket manufacturer, concrete mixing machinery

- Excavator Concrete Vibrator Excavator Hydraulic Vibrator Bunker Vibrating Truck

- Hydraulic vibration compaction Excavator Concrete Vibrator

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Concrete Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lisa liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Lisa liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile