Home > Products > Screen equipment > Gravity jig

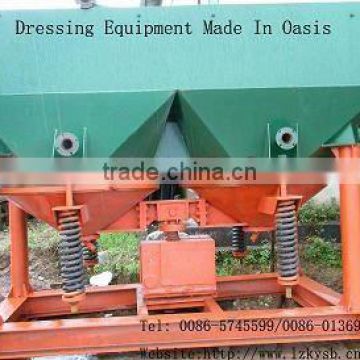

Gravity jig

- XiaMen

- T/T

You May Like

Product Details

| Condition | New | Type | Gravity Separator | |

| Production Capacity | 2-4 t/h | Place of Origin | Jiangxi, China | |

| Brand Name | OASIS | Model Number | JT1-1 | |

| Voltage | 380V | Power(W) | 2200 | |

| Dimension(L*W*H) | 1630/1310/2010 | Weight | 0.9 t | |

| Certification | ISO9001:2008 | Warranty | One year | |

| After-sales Service Provided | Overseas service center available |

Product Description

Ore dressing by Gravity Jig is considered as one of the major means for gravity beneficiation with the process characteristics being continued feed of ores to be beneficiated onto screen plate in Jigging Chamber, forming thick material layer. Upward flow is injected via screen plate periodically, allowing the lift of bed layer to be loose and flow to drop(or stop rising ).During this process, grains of different densities will displace relatively, with the heavy materials bring delivered into lower layer and the light material being transferred into the upper layer. Concentrate and tailings will be obtained after their being discharged respectively.

Saw tooth-wave Jig is a new type of energy conservation and highly efficient gravity separation equipment and developed based on the traditional Sine Wave Jig. The difference between Saw tooth .Wave Jig and Sine Wave Jig is that the pulsation curve for jigging is of saw tooth wave shape, with speedy upward flow and slow downward flow. Bed layer is elevated integrally and slowly dropped with a long effective loose time, allowing significant increase of handling capacity for unit serene surface, decrease of lower limit of grain size recovery and large save of make-up water for undersize fraction. Industrial tests carried out of Saw tooth Wave Jig and Sine Wave Jig for comparison showed that the recovery rate for operation of Saw tooth Wave Jig is raised by Sn:3.01%,Pb:1.63%,Xn:2.04% with water consumption being decreased by 30-75%.

Ore dressing by Saw tooth Wave Jig is capable of handling almost full sizes of mineral materials other than very fine material. It features simple process operation, heavy duty equipment handling capacity with final products being obtained through one time separation. Therefore, it has found a wide application in production. It is regarded as one of major means to cope with metallic ores such as iron and manganese ores of coarse, moderate and fine sizes and has found significant use in beneficiating tin and tungsten ores. Moreover, Jigging Method also can achieve a good result in processing primary ores bearing gold, tantalum niobium, titanium, zirconium and chrome and sand stones.

More density minerals to be separated in ores have, wider range the feed sizes have. For gold bearing placer, when feed grain size is less than 25 mm, separation may be carried out without size classification with the lower limit of recovery up to 0.05 mm. For ordinary metallic ores, size classified separation is conducted to effectively improve indexes for separation and to enhance handling capability for the equipment.

Model |

Area |

Stroke |

Times of stroke |

Feed Size |

Capacity | Feedwater quantity

|

Power | Overall dimensions |

Weight |

m2 | mm | r/min | mm | t/h | m3/h

| kw | mm | t | |

JT1-1 | 1 | 8.5-12 | 80-180 | <6 | 2-4 | 0.05 | 2.2 | 1630/1310/2010 | 0.9 |

JT2-2 | 2.28 | 12-17 | 80-180 | <10 | 4-8 | 1-3 | 3 | 3220/1550/2050 | 1.6 |

JT3-1 | 3.3 | 80-120 | <10 | 6-10 | 1-3 | 5.5 | 3180/2000/3030 | 3.26 | |

JT4-2 | 4.33 | 6.5-25 | 80-120 | <30 | 10-15 | 1-2 | 7.5 | 3600/1850/2600 | 4.6 |

JT5-2 | 4.86 | 15-25 | 80-120 | <10 | 10-20 | 1-2 | 7.5 | 3600/2000/2600 | 4.8 |

LTA1010/2 | 4 | 0-26 | 250-350 | 1-6 | 2-20 | 1-2 | 2.2 | 2800/1800/2300 | 1..3 |

300/450 | 2.7 | 0-26 | 320 | 12 | 3-6 | 2-3 | 1.1 | 1230/1270/1750 | 0.74 |

370/360 | 2.75 | 5-25 | 2-5 | 6 | 1-3 | 2-3 | 1.1 | 1000/600/1600 | 0.24 |

Contact Us

- Shicheng Oasis Mineral Equipment Manufacturing Co., Ltd.

- Contact nameAllen Wen Chat Now

- Phone0086-797-5745599

- AddressIndustrial park Shicheng,Ganzhou city,Jiangxi,China., Ganzhou, Jiangxi

Product Categories

New Products

-

Vibrating screen

-

Vibrating screen

-

Drum (sileve) screen

-

Drum (sileve) screen

-

Rotary spiral chute

-

high efficiency circular vibrating screen

-

YK high quality mining machine vibrating screen

-

hot sale of best sand Vibrating Screen

-

new type vibrating screen/ Powder vibrating screen/Oil Vibrating Screen

-

Stone/Gold Vibrating Screen with ISO

-

high efficiency vibrating screen/energy conservation environment vibrating screen

-

Circular vibrating screen/high speed vibrating screen

-

vibrating screen for mining industry

-

High Frequency Vibrating Screen/Composite Vibrating Screen

-

Trommel screen/Drum vibrating screen/simple construction vibrating screen

-

rotary vibrating screen/high efficiency energy conservation environment friendly large vibrating screen

-

Favourable Drum screen/rotary drum screen/waste water treatment special rotary drum screen

-

drum screen/trommel drum screen/drum screening machine/drum screen trommel screen

-

low noise drum screen /salt works equipment drum screen

-

new design drum screen /low noise large capacity rotary drum screen

-

low price Drum screen on sale with ISO

-

Compost drum screen/large capacity rotary trommel screen/drum screen

-

High quality drum screen /hot sale

-

professional spiral classifier design, high efficiency \good quality \energy saving \spiral classifier

Popular Searches

- distillation

- antimony ingot

- antimony metal

- sb

- antimony ore

- mining machine

- gravity separating machine

- energy saving

- distiller

- distillation equipment

- decanter centrifuge

- chrome ore

- mining equipment

- iron ore

- mining machinery

- spiral chute

- shaking table

- magnetic separator

- mineral separator

- spiral concentrator

- processing plant

- spiral separator

- washing plant

- molybdenum ore

- flotation machine

- flotation cell machine

- spiral classifier

- flotation cell

- oil extractor

- coconut milk separator

Recommended Products

- Yosion Technology YX-RSD02 Desktop Rotary Sample Divider;Sample Splitting;Automatic sampling equipment

- Yosion Technology YX-RSD20 Rotary Sample Divider;Sample Splitting;Automatic sampling equipment

- 150Tph Movable Gold Trommel Wash Plant Gold Sand Separator River Gold Panning Plant for Sale

- Alluvial Gold Mining Equipment Trommel Washing Plant Gold Separator

- 20TPH Rotary Trommel Drum Wash Plant Drum Screen Washing and Screening Equipment Mobile Gold Processing Plant

- Small Mobile Scale 5-10Tons Gold Ore Processing Equipment Gold Washing Machine Gold Trommel Screen

- 150tph Mobile Gold Diamond Panning Equipment Most Sold 2021 Gold Separating Machine Mining Shake Table

- Best Cheap Small Gold Mining Trommel Screen Dredging Machine For Sale

- Customized Gold Mining Equipment Trommel Washing Plant Gold Separator

- Mobile Mining Equipment Gold Washing Trommel Plant Gold Recovery Plant

- High Capacity Mobile Gold Mine Equipment 200Tph Diamond Washing Machine Wash Plant Placer Alluvial Gold Scrubber With Sluice Box

- Scrap Gold Mining Machine/ Gold Washing Plant/Gold Refining System For Sale

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Mineral Separator

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Allen Wen

Hi there! Welcome to my shop. Let me know if you have any questions.

Allen Wen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile