Home > Products > Brick making machine > fireclay brick making machine

fireclay brick making machine

- qingdao shanghai china

- T/T D/P D/A Credit Card

You May Like

Product Details

| Condition | New | Type | Hollow Block Making Machine | |

| Brick Raw Material | Clay | Processing | Brick Production Line | |

| Method | Vacuum Extruder | Automatic | Yes | |

| Capacity | 12000-16000PCS per hour | Place of Origin | Henan, China | |

| Brand Name | hengxin | Model Number | JKB50 | |

| Voltage | 380v | Power | 187KW | |

| Dimension(L*W*H) | 4850*5250*2600mm | Certification | CE,ISO | |

| Warranty | 2 years | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Fireclay Brick Making Machine, Cellbrick Vacuum Extruder , Burnt Brick Making Machine, Red Brick Machine , clay brick extruder

Feature of Fireclay Brick Making Machine

- The drift of brick vacuum extruder uses the wear-resisting metal powder froth spray coating technology.

- The speed reducer gear is the hard tooth face.

- This two-stage vacuum brick extruder series are all welded by high quality steel,and to remove the welded stress by heat treatment

- Use floating trowel,wear-resistant lining ,design the applicable trowel according to the raw material to ensure the high output,low energy consumption,low maintenance and other advantages of the equipment.

- Rollers.steel.axles, gear and other important spare parts which are made by carbon steel and alloy steel through modulation or quench’s heat treatment procession so as to extend the service life.

Application and Raw Material of Fireclay Brick Making Machine

To produce various solid and hollow brick by use of shale , coal ganue, coal ash , industrial tailing , sandy soil and river silt and etc to meet the need of reforming wall materials.

Using this device technology, we can change waste into treasure and save energy consumption,

it will do much to economy benefit and social benefit

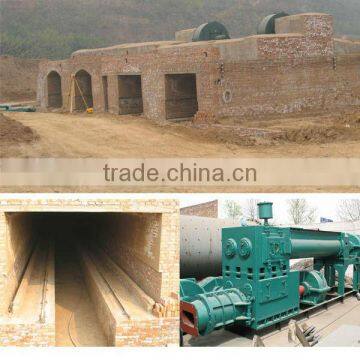

Samples of the finished block from fireclay brick making machine

Our service

1. Provide customers with various brick making equipments,

2. provides services like process design, kiln design, workshop design

3. Also,we have a professional team of engineers to do clay brick machine installation,

training workers ,imparting technical instruction to our buyers,

4. After brick machine running, we have special aftersales service department to provide

spare parts, machine problem fixing.

Detailed photo of fireclay brick making machine

Specifcations of Fireclay Brick Making Machine

Business Card

Work Flow Diagram

Notice

Theabove production line is standard, some machines will be added or deleted according to your soil condition.

So we suggest you can inform us your soil condition when you contact us , thank you.

The development history of fireclay brick making machine

- Single stage

The primary extruder is without mixing system.This machine is also single stage structure which makes the whole

set compact and reasonable.Mixing by machine saves time and effort.The raw materials agitation is relatively

uniform which makes the end bricks color and quality of qualitative improvement.

- Compact stage

Simple extruder with mixing box or not belongs to the first generation.The next stage came with the application

of vacuum technology.A vacuum chamber is added before extruded portion.The operators can see the internal

workings via the side observation room.This is a true stage of quality improvement.After vacuum stage,

the intensity of the mud is much strengthened.Soft mud pieces need second setting but the bricks made by the

vacuum extruder can burned directly after cutting.This is also a milestone of reducing the production cost.

- Double stage

Double stage is another upgrade of clay brick extruder.You can combined it into T structure or straight

structure.The auger of the machine is coated with wear resistance metal.This machine is suitable for

producing all kinds of cellbrick with material of gangue,shale,fly ash as well as clay.

Contact Us

- Gongyi Hengxin Material Trading Co., Ltd.

- Contact nameLaura Kang Chat Now

- AddressShihuiwu Industrial Area

Product Categories

New Products

-

second hand vacuum soil brick extruder

-

best quality vacuum clay fire brick making machine

-

JKB45 used vacuum clay mud brick extruder

-

tunnel kiln for sintered clay mud block making machine

-

vacuum extruding style automatic hollow/solid clay brick machine

-

large output daily automatic extruding clay hollow brick making machine

-

semi-automatic small ashfly/cement brick shaping machine

-

china cost-efficient low price hollow cement brick machine

-

cheap coal cinder manual brick making machine

-

mechanical pressure traditional porous concrete brick molding machine

-

salable in africa area professional design cheap semi-automatic concrete hollow brick machine

-

easy operation small hollow concrete block machine

-

bestselling semiautomatic cement/cinder/ashfly brick block machine

-

ISO certification construction manual cement hollow brick making machine

-

hydraulic style cement color pavement brick making machine

-

hydraulic cement color brick making machine

-

for making cement hollow block best seller semiautomatic hydraulic concrete brick machine

-

low manual concrete hollow brick machine price

-

with competitive price concrete baking-free brick machine

-

cheap price sewage charcoal powder forming machine

-

china manufacturer for screw propulsion coal rod extruder

-

factory supplier making coal rod machine

-

coal rod maker / cinquefoil shape charcoal stick making machine

-

charcoal powder briquette extruding machine coal briquette extruder (86 15937198193)

Popular Searches

- Sand Making Machine

- Sand Making Production Line

- building model making

- Asphalt Mixers

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- Asphalt Concrete Mixer

- Mobile Asphalt Mixer

- Asphalt Bitumen Mixer

- Asphalt Mixer Plant

- vehicle equipment

- paver

- Making Machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- Asphalt Drum Plant Bitumen

- double drum

- Brick Making Machinery

Recommended Products

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker with Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Laura Kang

Hi there! Welcome to my shop. Let me know if you have any questions.

Laura Kang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile