Home > Products > Plastic Pipe Production Lines > Full Automatic UPVC/PVC pipe belling Machine

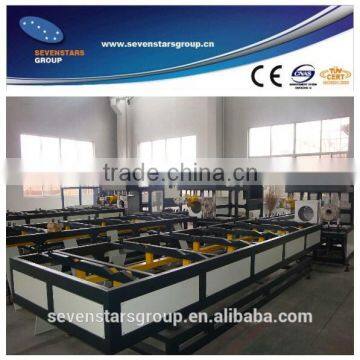

Full Automatic UPVC/PVC pipe belling Machine

- shanghai

- T/T

You May Like

Product Details

| Condition | New | Application | Pipe | |

| Plastic Processed | PVC | Screw Design | Other, no | |

| Automatic Grade | automatic | Place of Origin | Jiangsu, China | |

| Brand Name | sevenstars | Model Number | SGK | |

| Voltage | customized | Power(W) | depend on the model | |

| Dimension(L*W*H) | depend on the model | Weight | depend on the model | |

| Certification | CE and ISO | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

PVC pipe Belling Machine1.200mm - 500mm

2.low price,qualified

3.easy to operate

4.national Standard

Full Automatic UPVC/PVC pipe belling Machine

Main technical parameter:

pipe expand range (out diameter) | Φ200-Φ500mm |

control method | full-automatic control |

hydraulic system pressure rate | 20 – 50 Mpa |

Oil label | No.40/hydraulic oil |

Hydraulic pump power | 2.2KW |

Hydraulic pump vavle | from Taiwan |

Hydraulic cylinder,stem,hydraulic pipe | Festo of German |

Heating power | 6KW |

Heating barrel highest warming | 250 |

Air pressure | 0.4~0.6Mpa |

Cooling water pressure | 0.2~0.3Mpa |

CPU | PLC: Simens of German |

Detection components | Switch(Schneider) |

Temperature control unit | Omron of Japan |

Common electrical equipment | joint-venture Schneider |

Machine set weight | 1.5 T |

Belling center | 1000mm±50mm |

Configuration:

1.The whole operation process of the belling machine both adopt human-machine interface touch screen from Japan Mitsubishi by PLC , the belling is operated automatically.

2. The heating mode adopts heating pipe in interior and exterior by double work position infrared ray, the hot air circulating equipment is installed the interior of the heating box,it makes the heating of the pipe fast and symmetrical and even improve the work efficiency .

3. The process of the clamp and belling both adopt hydraulic equipment,the hydraulic pump adopts variable vane pump from Taiwan.

4. The cooling system adopts vacuumize and water cooling mode,the effect is higher twice than the wind cooling.

5. Photoelectric switch adopts theautonics.

6. Pneumatic element adopts thequanwei .

The spare parts with the machine:

a.A copy of the Chinese- English instruction book

b.Inner hexagon spanner : 1 set

c.Photoelectric switch: 2 pieces; panel knob: 2 pieces; contactor: 2pieces; Protective tube: 1 set.

Contact Us

- Zhangjiagang Sevenstars Machinery Co., Ltd.

- Contact nameMabo He Chat Now

- Phone86-512-58978656

- AddressBldg. 1, Hongqi Road, Modern Agriculture Demonstration Park, Zhangjiagang City, Jiangsu Province, China, Suzhou, Jiangsu

Product Categories

New Products

-

China pvc profile production line

-

pvc profile pinch plate extrusion line

-

PVC special profile extrusion line

-

WPC embossing machine

-

Wood plastic profile embossing machine

-

Wood plastic board embossing machine

-

Wood plastic board sanding machine

-

PVC ceiling extrusion line

-

PVC ceiling extrusion line

-

PVC ceiling panel making machine

-

PVC wall panel making machine

-

Wood plastic profile production line

Popular Searches

- plastic extruder

- extrusion machine

- twin screw extruder

- aluminum tube production line

- Foam Board Equipment

- production line

- extruding machine

- Production Equipment

- extrusion line

- Belt Making Machinery

- Extruder Machine

- Pet Strap Making Machine

- Pet Belt Making Machine

- Bubble Film Making Machine

- Cable Manufacturing Equipment

- plastic extrusion

- plastic machinery

- extruding equipment

- wire extruder

- cable extruding line

- Cable Extruder Machine

- Cable Manufacturing Machine

- decorative line

- Extrusion Production Line

- Engineering Lab Equipment

- eps machinery

- cement production line

- pipe making machine

- pipe production line

- Board Making Machine

Recommended Products

- xps foam board production line

- HDPE Pipe Production Line

- Petrochemical Granulation Equipment Use Polyolefin Pelletizing Die Plate

- Spare Parts Pelletizing Knife Holder Used for Granulating Polymer

- Spare Parts for Fixing Pelletizer Knives Pelletizing Cutting Disc

- PP PE underwater granulation system use knife rotor

- Industrial Cutting Blade for Underwater Pelletizing Unit for Plastic Granules Manufacturing

- Intensive Heated Channel Die Plate for Producing PP PE Particles

- Underwater Pelletizing Unit Use Pelletizing Blade for Plastic Granules

- Pelletizing Die Plate for Underwater Polyethylene Pelletizing System Extruder

- Metal-ceramic Composit Pelletizer Knife for PP PE Plastic Granule Extruding

- Flexible Pelletizer Knife Holder for Underwater Cutting Plastic Granules Line Carrier for Pelletizer Knives

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Extruder

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Mabo He

Hi there! Welcome to my shop. Let me know if you have any questions.

Mabo He

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile