Home > Products > Rotary Kiln > 150~1000 t/h Active lime production line with CE,ISO

150~1000 t/h Active lime production line with CE,ISO

- nearest port

- T/T Credit Card

You May Like

-

150 t/d active lime rotary kiln production line of Kefan

-

1000 t/d active lime rotary kiln production line

-

Customizable ceramic sand process manufacturer in China

-

High yield shale ceramic sand production line for Sale

-

Kefan fly ash ceramic sand production line

-

Newest Restore titanium rotary kiln manufacturer with ISO

Product Details

| Type | Other, active lime production line | |||

| Brick Raw Material | Lime | Processing | Brick Production Line | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | 150 t/d | Place of Origin | Henan, China | |

| Brand Name | Henan Kefan | Model Number | KF | |

| Voltage | industrial voltage | Power | depend on model | |

| Dimension(L*W*H) | depend on model | Certification | BV/CE/ISO | |

| Warranty | 2 years | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

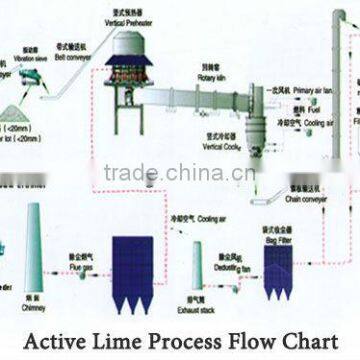

Active lime rotary kiln production line description:

Qualified limestone stored in silos, by the elevator Lift and transported into the preheater at the top of the silo. Preheater top hopper, the bottom two material position control feeding quantity, and then through the next feeding tube will be evenly distributed to the preheater limestone indoor.

Limestone preheater kiln is heated to 900 ° C by 1150 ° C flue gas and about 30% decomposition, by the hydraulic plunger push into the rotary kiln, rotary kiln sintered limestone and decomposed into CaO and CO2. Generated after decomposition of limestone, limestone into the cooler, the cooler was bubbled into the cold air cooled to 100 ° C at the discharge. The hot-swappable 600 ° C hot air into the kiln and gas combustion. Exhaust fan in blended with cold air entering through the baghouse, and then the exhaust fan into the chimney.

Main advantages of Active Lime Process Flow Chart:

1.Good quality,and high output,suitable for larhbe-scale activity of lime production lime and large-scale production.

2.Stable production,all the production with the negative pressure,air flow and higher security.

3.Simple structure,easy control and beneficial operation and maintenance.

4.Fine grade limestone can be calcined,full use of mine resources.

5.Low heat consumption per unit of product,installation in vertical kiln can take advantages of exhaust warm limestone,greatly reducing the fuel consumption.

6.Making full use of industrial waste gas as a fuel for lime burning(such as blast furnace exhaust gas,acetylene tail gas,charcoal blue exhaust,etc.)

7.Kiln head adopts the design of vertical cooler integrating kiln head cover, The construction area is small,good sealing,

8.Environment protection,the adoption of pulse bag filter collecting dust,discharge concentration less than 50mg/Nm3 and below national emission standard(less than 100mg/Nm3).

9.High automation level,the adjustment of production system operation,control and alarm.

| Design capability (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime Light heat dolomite | Active lime Light heat dolomite | Active lime Light heat dolomite | Active lime Light heat dolomite | Active lime | Active lime | Active lime | Active lime | Active lime | Active lime | Active lime | |

| Preheater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Round Prehe ater | Vertical Polygon Prehe ater | Vertical Polygon Prehe ater | Vertical Polygon Prehe ater | |

| Rotary Kiln | Standards(m) | 2.4×40 | 2.8×43 | 3×50 | 3.2×50 | 3,3×55 | 3,6×55 | 3.8×58 | 4×60/4.2×50 | 4.3×60 | 4.3×65 | 4.8×68 |

| Effective volume(m3) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Burning temperature(°C) | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350/ 1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooling | Vertical round cooler | Vertical round cooler | Vertical round cooler | Vertical round cooler | Vertical round cooler | Vertical square cooler | Vertical square cooler | Vertical square cooler | Vertical square cooler | Vertical square cooler | Vertical square cooler | |

| Fuel | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | coal gas Coal fine | |

| Heat Rate(kj/kg CaO) | 5300/ 5000 | 5300/ 5000 | 5300/ 5000 | 5300/ 5000 | 5300/ 5000 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

Active lime rotary kiln production line key equipment:

1.Vertical preheater

Low voltage drop preheater,smoke in the preheater,reduce the resistance losses, reduce power consumption .From the high temperature ,hot flue gas inlet,directly through the material layer,and limestone fully preheated temperature heat, limestone can reach 900°C,about nearly 30% of limestone decomposition,emissions than 270°C temperature.

Adopts hydraulic push rod feeding to kiln.

Preheater coping with the bunker material level program control,the ultrasonic material level plan,ecr realize material level discretion alarm,interlocking feeding system,ensure preheater material layer highly stable.Preheater adopts hanging brick outside except the top ,the rest part adopts the fire-resistant pour families,brick type is less ,masonry is simple.

Preheater sports equipment is less,equipment maintenance is small.

2.Rotary kiln

Adopt thick short type rotary kiln,Such as diameter 3.5m,kiln long 55m,saves the land.

Adopt speed motor drive kiln body,and is equipped with auxiliary motor,stable work,regulate flexibly.

With spring of preheater sealing structure,simple,reliable and the seal effect is good.

3.Prependicular type cooler

Cooler is divided into four regions,and can control alone.

Cooling wind and heat materials contact directly and cooling effect is good,the gray temperature higher than the environment temperature about 80°C,secondary air temperature can be preheated about above 600°C ,beneficial to the roasting.Cooler has no moving parts,equipment maintenance less.

4.By four-channel coal combustion pulverized coal burners(pulverized coal tube)

Four-channel coal burner device,is a big speed difference in the cement industry new burner,can be widely used.Using the principleof coincidental association flow has big speed difference,speed and angle of pulverized coal ejective adjustment,form in the area of the burner center,can promote second negative pressure area fully mixing wind and the coal,coal extremely block heats up,reach ignition temperature.

Once,about 8% less air combustionair quantity of theory;Coal in wind in nozzle out about 25-speed 35m/s; Spin in LiuFeng on the nozzle out approximately 120-speed 180m/s; Dc wind on the nozzle of the jet speed in 200m/s for 140-;Center for a wind of qir volume air about 2-6%.

5.End of waste gas treatment using LCM type long bag impulse precipitator.

The advantage of the filter bag for LCM type long bag impulse precipitator integrate points room counter blowing and pulse ash blowing clear , lengthen the compressed air power, play full role of blowing out dust to prevent dust control and attached again,so as to improve the filtering velocity,saving energy,extend out dust filter bag life effect.

The flame shape can be adjusted flexibly,to adapt to the roasting need plume lime.

The adaptability of coal,flam mable inferior coal.

Calcination won't be partial fire and brush kiln skin.

Contact Us

- Henan Kefan Mining Machinery Co., Ltd.

- Contact namejenny wang Chat Now

- Phone0086-0371-67996718

- AddressXushui Industry Zone, Zhengzhou, China , Zhengzhou, Henan

Product Categories

| Baler machine | Ball Mill | Crushing Machine | Dryer |

| Granulating Machine | Mill Machine | Mobile Crushing Plant | New Products |

| Ore Beneficiation | Production Line | Raymond mill | Rotary Kiln |

| Sand Making Machine |

New Products

-

High efficiency 1.8*45m Gypsum Rotary Kiln Suppiler in China

-

2013 High efficiency Synthetic rutile kiln for sale

-

High efficiency cement shaft kiln used for cement plant

-

metallurgy rotary kiln for india sale with best price

-

72-5000t/d magnesia rotary kiln in China with best price

-

Kefan High Quality Hot Saling KLG Rotary Kiln With Best Price

-

Kefan Supply High Quality Directly Heated Rotary Dryer With Best Price

-

Kefan CE/ISO Approved High Quality Rotary Kiln For India Sale

-

Kefan Professonal Cement Rotary Kiln Supplier +0086-371-86678079

-

Kefan Professonal Rotary Kiln Supplier with good price

-

High quality rotary kiln cylinder cooling machine manufacturer

-

6000tpd rotary kiln in cement production line

-

Kefan rotary kiln for cement plant-+8613838093345

-

3000t/d cement machinery rotary kiln in cement plant

-

China good quality rotary kiln for cement plant

-

Good quality calcined magnesite rotary kiln for sale

-

ISO approved Limestone rotary kiln for india sale

-

Hot Sale Dual/four Channel Coal Burner

-

High efficiency coal pulverizer burner for sale with ISO

-

2014 hot selling industrial coal burners

-

Hot sell rotary dryer coal burner for boilers

-

2015 hot sale rotary kiln equipment with ISO for sale

-

CE and ISO approved ore rotary kiln widely used in world

-

High quality mineral rotary kiln for Southeast Asia

Popular Searches

- sand making machine

- sand making production line

- building model making

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- asphalt concrete mixer

- mobile asphalt mixer

- asphalt bitumen mixer

- asphalt mixer plant

- vehicle equipment

- paver

- making machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- asphalt drum plant bitumen

- double drum

- brick making machinery

- block machine

Recommended Products

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker with Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

jenny wang

Hi there! Welcome to my shop. Let me know if you have any questions.

jenny wang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile