Home > Products > Machining center and Engraving and milling machine > CNC Vertical Machining Center BVMC850

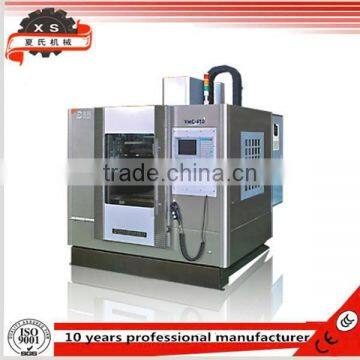

CNC Vertical Machining Center BVMC850

- shenzhen

- T/T L/C D/P D/A Credit Card

You May Like

-

VMC(VC)1000L Vertical machining center (line track)

-

vertical machine center for saler VMC850

-

VMC1060 Hign precision CNC vertical machining center

-

VMC850 cnc machine center for mold making, vertical machining center

-

VMC(VC)610 Vertical machining center (hard track)

-

CNC Gantry-type Machining Center XH2412

Product Details

| Condition | New | Type | Vertical | |

| Brand Name | XiaShi | Model Number | BVMC850 | |

| Voltage | 380v/50Hz | Power(W) | 18KVA | |

| Dimension(L*W*H) | 2400*2500*3000mm | Weight | 7000kg | |

| Warranty | 1years | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

DESCRIPTION

1)Casting is made by advanced nano Meehanite. Such material is very stable; It can make sure

there is no distortion after long term use. Main structure adopts ANSYS limited unit software

analysis, to reach highest and best rigid structure design.

2)We design strong structure to build column, avoid and reduce distortion while cutting.

3) Nut integrated design

Nut block for screw and main machine body are built together for every axis, with this design, machine will get better rigidity, and won't lost precision while heavy cutting and acceleration

movement impact

4)Adopt three slide blocks for single axis

Adopt three slide blocks for single axis will enhance load capacity around 30%, with this

method will improve the load capacity.

5)Optimized structure of heavy rail linear guide

Comparing with ball screw guide, its lead capacity and damping properties has been improved

30% and 15% respectively: Comparing with hard track guide, dynamic motion function has

been improved 300%, at the same condition, the machining efficiency will be 2%-15% better,

life of machine will be 36 times longer, so without shutting the machine down to repair, it will

save 5-20% precious time

6) High accuracy, high inflexible principal axis

Belt transmission type principal axis can provide biggest RPM800012000. Special designed

principal axis bear configuration, show us the outstanding rigidity of principal head. Precious

ball screw assembly is adopted for X, Y and Z axis, such screw is pre processed to ensure best precision and minimize the error.

7)Disc style ATC system

8). Advantage of system

1. MITSHBISHI choose 64bite high speed CPU and PLC as the heart if control system, not

only improve data processing speed, but also raise machining efficiency obviously.

2. Most advanced hardware is adopted, it is advantage to enhance the ability of high speed

processing and the ability of compensation,

3. System support various language and can be used worldwide.

4. Principal axis is connected by parallel bus.

Servo system

Swift response and stable location loop control system will be most beneficial while machining

process, it also realize stable control of speed up and speed down.

1. Adoption of the medium and small model servo motor and high-resolution decoder

2. Enhance the rigidity of machine tool

3. Special characteristics in stable control of speeding up and down

4. Reduce parts processing time and improve the machining precision of parts.

Parameters

CNC Vertical Machining Center | Unit | BVMC850 |

X/Y/Z axis travel | mm | 800x500x600 |

Table upper surface to spindle nose end face | mm | 120-720 |

Table to spindle nose | mm | 570 |

Positioning Accuracy (mm) | mm | ±0.005 |

Repeatability Accuracy (mm) | mm | ±0.003 |

Spindle Speed (rpm) | mm | 8000/10000/12000 |

Spindle bore taper |

| NO.40 |

Table dimension | mm | 1000x520 |

Max. load on table | kg | 800 |

T shape groove | mm | 18TxP100x5 |

Power (X/Y/Z) | kw | 1.8,1.8,1.8 Fanuc 2,2,2 Mitsubishi |

Rapid speed (X/Y/Z) | mm/min | 24000/36000 |

Cutting speed (X/Y/Z) | mm/min | 12000 |

Tool holder model |

| BT40 |

Tool capacity | pcs | 16/20/24 |

Tool exchange time(T-T/C-C) | sec | 7/13(3.5/7) |

Spindle power (30min/successive) | KW | 7.5/11 Fanuc 5.5/7.5 Mitsubishi |

Rated Power | KVA | 22 |

Air power | Mpa/L/min | 0.6/200 |

Machine height | mm | 3000 |

Floor space | mm | 2400x2500 |

Machine Weight | Kg | 7000 |

Optional System

Japan Mitsubishi | Japan FANUC | Germen SIEMENS | Taiwan SYNTEC |

|

|

|

|

Optional Auto Tool Change (ATC System)

Umbrella Type | Arm Type(Disc Type) | ||

16pcs | 20pcs | 16pcs | 24pcs |

|

| ||

Optional 4th Axis

| CNC-201R | Hold Dia. 200mm | Taiwan |

CNC-251R | Hold Dia. 250mm | Taiwan | |

CNC-321R | Hold Dia. 320mm | Taiwan | |

TK13315E | Hold Dia. 315mm | China |

Optional Parts

Spindle Oil Cooler | Tool Presetter | Chip Convoyer |

|

|

|

Main Application

BMVMC series CNC vertical machining center is a cooperative designed product with German company. We adopted advanced international idea of designing a modern structure machine

tool and used the latest software to analyze various technical data. Most reliable and high

quality components and spare parts have been introduced to this nice machine tool. No matter

precise elements machining or moulds processing, BMVMC series machining center will offer

you excellent performance, high efficiency, higher accuracy and long-term stability.

Suitable for: machining parts of automobile, mold industry and so on.

Picture details

If you have any other requirements for the size,please do not hesitate to contact us,or you can advise us your ideas or thoughts for the machine,we can kindly design for you and communicate with you for the details.

Contact Us

- Guangxi Xiashi Machinery Equipment Co., Ltd.

- Contact nameChristina Chen Chat Now

- Phone86-772-2729581

- AddressNo.68-8 Hangyin Road, Liuzhou, Guangxi

Product Categories

New Products

-

VMC850L vertical machine center

-

Dependable Performance VMCL850 cnc vertical machine center lathe machine For Sale

-

VMC1100B hard track vertical machining center

-

VMCL600 vertical machining centers and milling machine

-

CNC Vertical Machine Center VMC(VC)1000

-

VMC(VC)640LH Vertical machining center (line track)

-

VMC(VC)850L Vertical machining center (line track)

-

Special discount for lathe and machine center etc. VMC(VC)640L Vertical machining center (line track)

-

Fanuc CNC Vertical Machine Center VMC850

-

Dependable Performance CH7525 lathe machine for steel CNC turning center with good price

-

VMC650L Linear guide rail series CNC Vertical Machining Center

-

CNC Engraving Machine DX80120

-

CNC hard track vertical 5-axis machining center VMC1300A

-

line-rail vertical CNC 5-axis machining center VMCL1100

-

CNC hard track vertical 5-axis machining center VMC1800A

-

High speed CNC vertical 5- axis machining center VMC1650A for sale

-

Dependable Performance DX8080 mini cnc milling machine with cheap price

-

CNC Vertical Machining Center with High Precision XH716

-

Competitive price with high quality CNC Engraving Machine DX5050,cnc milling machine

-

Hot DX6060 cnc engraving and milling machine With high performance

-

CNC Engraving Machine DX80100,Metal engraving machine,cnc engraving and milling machine with low price

-

CNC Engraving Machine DX8080

-

CNC engraving and milling machine BMDX10080

-

BMDX8060 CNC metal engraving and milling machine with high performance

Popular Searches

- extruder component

- screw barrel

- screw element

- rapid prototype

- prototyping

- plastic parts

- 3d model

- Titanium Alloy

- metal prototype

- api coupling

- grease fitting

- iron machining

- Stop Service

- 3d Printing Service

- Assembly Service

- oil nozzle

- bakelite knob

- auto components

- Tool Accessory

- Grease Nipple

- Plastic Auto Part

- rapid prototyping

- Final Inspection Service

- Machine Tool Parts

- Mechanical Transmission Parts

- precision plastic machining

- drill bushing

- motorcycle fittings

- Fastener Part

- rubber piston

Recommended Products

- Busbar Leveling Machine | Auto Feed for Bent Busbar Recovery | CE/ISO9001

- Servo CNC Busbar Bending Machine High Precision | Auto Angle Control | CE/ISO9001 for Switchgear BT-CB1600S/CB1600

- CNC Busbar Punching Shearing Machine - Auto 3-in-1 (Punch/Shear/Bend) | CE ISO9001 | 0.1mm Precision

- CNC Busbar Chamfering Milling Machine

- Mechanical Manufacturing, Welding Parts Processing, San Yong Machinery, High Precision, Complex Curved Surface Accurate Forming

- small machining center|vertical machining center

- YORNEW Tools Small CNC Milling Machine

- HL Parts | Customized Anodizing Aluminum Parts Mechanical Metal CNC Processing Services CNC Turning And Milling Part Service

- HL Parts | Factory Custom Motor Cover CNC Machining Anodic Oxidation Parts

- HL Parts | Custom CNC Machining Service,CNC Machining Parts, CNC Milling Machined Anodized Aluminum Parts Rapid Prototype

- HL Parts | Black Bakelite Corrugated Hand Wheel Threaded Keyway Valve Switch Knob Female Star Knobs

- HL Parts | Custom high precision alloy aluminum stainless steel hot forging die casting machining service grey iron sand casting

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machine Tools > CNC Machine Tools

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Christina Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Christina Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile