Home > Products > Textile and Nonwoven Industry > Apparel Fabric Cutting Blade China OEM With High Wear Resistance

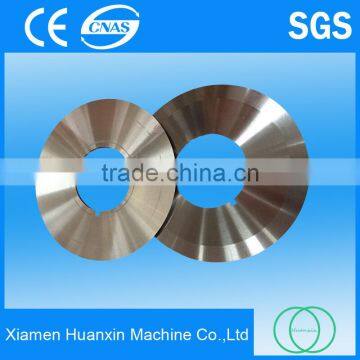

Apparel Fabric Cutting Blade China OEM With High Wear Resistance

- Xiamen

- T/T L/C D/P D/A Credit Card

You May Like

-

Hydraulic Standard Press Brake Die and Press Brake Tooling

-

High Quality Amada Press Brake Tooling With High Level Precision

-

High Precision Amada Press Brake Toolings Bending Tool

-

Punch and Shear Dies for Press Brake Machine

-

Hydraulic Bending Machine Tooling Dies Bending Steel

-

CNC Press Brake Tooling 2v Die for Bending Machine

Product Details

| Place of Origin | Fujian, China | Brand Name | Huanxin | |

| Model Number | K-89 | Type | Other, Cutting parts |

Product Description

Apparel Fabric Cutting Blade China OEM with high wear resistance:

Operational Progress:

Steel-choosing→Blanking →Forging Steel →Rough Processing →Heat treatment →Finishing→Testing

Knives are available with polished side faces ,High cost performance ,Punctual delivery .

Fabric Cutter Blade are manufactured to a thickness tolerance of ±0.002mm-0.003mm(±0.00007 inch-±0.00012inch).

Parallelism tolerances is within 0.003mm (0.00012 inch) These are all prerequisites for the best possible slitting results.

Materials : 9CrSi ,6CrW2Si , H13 ,Cr12MoV ,G1 , G2 ,G3 and etc .

Steel-making by medium frequency furnace

Huanxin company can meet special requirements for materials . In order to guarantee the quality ,the company imported the spectrometer from Germany and is equipped with various testers,such as tensile tester,impact testing machine,metallography analyzer and so on .

Electro slag remelting

The largest ingot can reach 3 tons in Huanxin company .The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects . The segregation of the ingot (called macro-segregations ) are substantially eliminated and the segregations of crystals (called macro-segregations ) are significantly reduced .

The ESR remelted material improve following mechanical characteristics :

Improved toughness due to increased homogeneity and isotropy

Improved creep resistance properties

Best fatigue strength and tenacity properties as well as outstanding tensile strength

Improved purity

Forging steel

The largest electro-hydraulic hammer is 4.5 ton .And more than 6 skilled technicians work for us .After forging ,the inside microstructure becomes much closer and the metal grain size becomes much smaller . It can evevate the characteristics and quality of the knife ensuring a longer life .

Rough processing

No less than 40sets of processing equipment in the rough processing workshop of Huanxin company , including lathe ,milling machine , planer , drill machine etc. Skilled workers are employed in its rough processing workshop .

Heat treatment

Huanxin company has independent workshop for heat treatment . Couples of skilled technicians work here . Actually , most blades ( thickness ≤100mm) can be fully hardened . Thus ,the blades can be used after repairing until the size reached the minimum design dimension .

Finishing

Huanxin company has more than 35 sets of processing equipment including internal grinder , external grinder , surface grinder ,CNC grinder ,electric spark CNC wire-cut etc. The company can produce the shearing blades with 5500mm in length and slitting knives with 1300mm in outside diameter .

Testing

Various testers are put to use for testing its products in Huanxin machine company . They are including tensile tester , impact testing machine , metallography analyzer , harmless flaw detector , magnetic powder inspection , hardness tester , caliper rule , microcalliper , etc . Testing is carried out after each step . And every product has a unique track number . Thus it is easy to trace back anytime

Payment Terms:

♦ 30%−50% down payment in advance and the balance before shipment.

♦ Paypal,Westen Union,T/T, Unionpay ,Excrow Service,Visa,LC,etc.

Samples Offering:

♦ Samples is available.

♦ Freight collect.

Delivery Time:

♦ 5-10 Days For Few Quantity.

15-25 Days For Large Quantity.

♦ Personalized Customization Is Acceptable.

Transportation:

*5-10 Days by Express.(UPS,DHL,TNT,FedEX,EMS,etc.)

*2-3 days by Air (EXW,FOB,FCA,CIF,CPT,DAF,DDP etc.)

*25-45 days by Sea (EXW,FOB,FCA,CIF,CPT,DAF,DDP etc.)

Material and hardness are much important to the work life of blades ,according to over 10 years' experience ,Huanxin Machine will provide you professional advice . We will recommend you best material and hardness according to the applications of blades .We want to know the following details :

What kind of the steel ?

The maximum tensile strength of the steel ?

The minimum and maximum thickness of the steel ?

We custom blades according to your drawing or description .In order to provide prompt and accurate quotation , it's better that you can provide us the quantity , drawings , cutting application and etc of blades .

All of your inquiry and emails , we will give reply within 24 hours . No excuse for failure ,only the action for success.

Our enterprise spirit : Mutually beneficial cooperation .

Huanxin Machine Co., Ltd is located in Xiamen which is one of the most famous town for blades in China . The company has been committed to providing knives and blades of high productivity and high precision . From raw material , heat treatment to finishing ,Huanxin keeps track and exercises strict control over every piece ,in order to improve the performance of our products and production efficiency , at the same time reduce the production cost . By working with counterparts from western countries closely , Huanxin continues to innovate and pursues the better quality . Besides standard raw materials like 9CrSi , D2 , H13 , the company also has its own special materials which are specializing processing high tensile strength metal coils . Material-choosing , cutting performance improvement , professional advices are available here . Good material , skilled producing process and responsible after-sale service make our products popular at home and abroad .

1.What's price ?

Always we will quote you price based on drawings ,or you can tell us the dimension . Then according to your application and quantity ,we will send you quotation soon. The price is differ from different materials .

2.What's the material and hardness ?

According to your application ,we will recommend you the best material and hardness .

Optional Materials :9CrSi , 6CrW2Si , LD , D2 , Cr12MoV , H13 , G1, G2 ,G3 and etc .

Goodklife has developed some high alloy steel ,like G1 , G2 ,G3 etc . They are new materials developed independently by our company and excellent in high intensity , high hardness , high wear resistance , high toughness and so on . They can be used in both cold and hot shearing ,the life is 2-3 times longer than other blades made of normal materials .

Hardness : If hardness is high , when the blades meet higher tensile strength steel ,it is easy to crack . If the hardness is low , then the wear resistance is not good ,that means work life is shorter .

Contact Us

- Xiamen Huanxin Machine Co., Ltd.

- Contact nameArlene Lin Chat Now

- Phone86-0592-5790287

- AddressRoom7045,No.73-74, Huan Road, Heshan Street, Huli District,Xiamen, Xiamen, Fujian

Product Categories

New Products

-

OEM CNC Press Brake Tooling Machine Bending Blade

-

Standard Press Brake Tools / Punch Tool

-

Press Brake Dies/bending Tooling/mould

-

OEM Press Brake Mold,bending Machine Mold in Best Price

-

Dies for Bending Machine With High Precision

-

Hydraulic Press Brake Molds Standard v Block Bending Dies China Supplier

-

Punch Blade for Tagboard Cutting

-

Punch Blade/Knife for Tagboard Cutting

-

Transformer Pill Punch Press Die and Mold

-

Tooling Press Die Brake

-

Adaptor

-

CNC Press Brake Machine

-

CNC Amada Press Brake Tool for Sheet Bending Machine, Bending Mould

-

CNC Amada Bending Tool, Press Brake Tool

-

Amada Sectioned Lower Die Tooling Press Brake Machine Mould

-

Hydraulic Standard Press Brake Die&press Brake Tooling

-

Press Brake Punch and Die Tools,hydraulic Press Brake Tools

-

Metallurgy Industrial Blades,hydraulic Pendulum Guillotine Shearing Blades&shearing Machine Knife

Popular Searches

- carbon brush

- diamond segment

- circle cutter

- power tool accessory

- hcs

- power tool spare part

- angle grinder armature

- angle grinder carbon brush

- copper carbon brush

- silver carbon brush

- power tool carbon brush

- replacement carbon brush

- chain saw oil pump

- segment

- diamond cutter

- gang saw segment

- oscillating tool

- multi tool blade

- block cutting segment

- power tool part

- carbon brush set

- carbon brush replacement

- drill press stand

- bosch brush

- bosch electrical brush

- gangsaw segment

- blade segment

- slab segment

- circular brush

- diamond blade segment

Recommended Products

- MaAnt 21T Corrosion-Resistant Blades for Electronics Disassembly

- KNE Japan IKO Cross Roller Bearing CRBHV 4010AUU

- KNE Japan IKO Cross Roller Bearing CRBHV 4010A

- KNE Japan IKO Cross Roller Bearing CRBHV 3510A

- KNE Japan IKO Cross Roller Bearing CRBHV 3510AUU

- KNE Japan IKO Cross Roller Bearing CRBHV 3010AUU

- KNE Japan IKO Cross Roller Bearing CRBHV 3010A

- KNE IKO High-precision Modular Cross Roller Linear Guide CRWG2-75H

- KNE IKO High-precision Modular Cross Roller Linear Guide CRWG2-60H

- KNE IKO High-precision Modular Cross Roller Linear Guide CRWG2-45H

- KNE IKO High-precision Modular Cross Roller Linear Guide CRWG2-30H

- KNE IKO High-precision Modular Cross Roller Linear Guide CRWG1-70H

Find Similar Products By Category

- Industrial Equipment & Components > Universal Hardware Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Arlene Lin

Hi there! Welcome to my shop. Let me know if you have any questions.

Arlene Lin

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile