Home > Products > Light weight equipment > AAC Light Weight Block Machine in Malaysia AAC Block Plant

AAC Light Weight Block Machine in Malaysia AAC Block Plant

- Qingdao

- T/T

You May Like

Product Details

| Condition | New | Type | Other, AAC Block Making Machine | |

| Brick Raw Material | Sand | Processing | Brick Cutting Machine | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | 50000~300000M3/Year, from 30,000-300,000m3 | Place of Origin | Shandong, China | |

| Brand Name | Hongfa | Model Number | AAC | |

| Voltage | 220V-415V | Power | 400KW | |

| Dimension(L*W*H) | 6.0*1.2*0.6M | Certification | ISO9001-2000CE,SGS,BV | |

| Warranty | 1 YEAR | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Our company built in 1990, we have four factories in china ,our main products are AAC block plant ,concrete mixing plant , concrete block machine . we have pased ISO9001, CE, BV,SGS.

AAC light weight block machine in Malaysia AAC block plant

1 light weight ,Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay block and 1/5 common concrete.So use the Light block can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2 keeping temperature It has many are porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world.

have many kinds material,have lowest waste

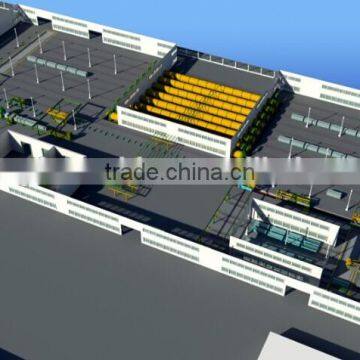

Producing process sketch :

1.Storage and processing of the raw material

2.Batching, mixing, pouring

3.Cutting, grouping

4.Autoclave curing and finished

5.Lateral plate returns, group mode with oil

6.Comprehensive utilization

German technolgy made in China aac machine , aac block production line 30000m3/year ---300000m3/year (Hongfa )

Main features of Hongfa AAC project:

1,Agglomerate lime is firstly crushed by jaw crusher, and then the granule lime is milled by energy-saving mill.

2,Mixing the fine grinding sands and the waste slurry for the slurry can improves effectively the stability of the slurry.

3,The slurry and powder are weighed by electronic measurement. The measurement and pouring of batching plant are controlled by central control room.

4,The pouring method adopts fixed point pouring.

5, It chooses the JQF 6.0 step by step cutting machine (Made in China). The maximum cutting size is 6.0×1.2×0.6m and the capacity of the cutting machine is about 400,000 m3 per year. The cutting precision reaches the China advanced level among the same size

6,The autoclave kettle adopts 2 upward-acting doors to decrease the time of the brick in and out of the autoclave and saves construction areas.

7,Using the integrated process layout, it is conductive to building warm insulate and automatic control of the line. At the same time, it reduces the cost of construction.

8,Using hydraulic transport system instead of travelling crane can improve the stability of the system and save the procedure of application for inspection.

9,The waste on the bottom is cleaned by the hanger with cleaner and then sent to the autoclave kettle for autoclaved maintenance to realize no hard waste for production.

10,Comprehensive utilization of the waste material, waste water, waste gas and rain water helps make full use of the source and reduce emissions.

11,In order to simplify processing and reduce the cost of production, manual work is needed to clean and oil the molds.

About the raw material ratio of AAC block :

Cement lime fly ash style aerated block raw material proportion

name | unit | Cement lime fly ash |

flash | % | 65-70 |

cement | % | 6-15 |

lime | % | 18-25 |

gypsum | % | 3-5 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.60-0.65 |

Casting system | OC | 36-40 |

Aluminum mixing time | S | 30-40 |

Cement lime Sand style aerated block raw material proportion

Name | Unit | Cement Lime Sand |

Sand | % | 55-65 |

Cement | % | 10-20 |

Lime | % | 20-30 |

Gypsum | % | 2-3 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.65-0.75 |

Casting system | OC | 35-38 |

Aluminum mixing time | S | 30-40 |

Reference: cement is 42.5 Portland or 42.5 common cement

Aluminum power paste calculate to use according to 600kg/m3

Remark: the accurate batching rate is adjustable according to the raw material locally

Aera and labour need :

Needs 24-32 labour for whole AAC factory running plant , the land needs 5600M2-10,000M2 according to different capacity.

Service:

We can give one year warranty time for free service , in the period , we can send our engineer to customers place for installaion and training . For any help in the machine whole using life , you can feel free to contact with our after sale deparment for 24 hours . We have set up many sale offices and after-sale offices around the world

IF you are interested in ,pls feel free to contat Linda at +86-15264934636 or add my skype: linda112637

Contact Us

- Shandong Hongfa Scientific Industrial & Trading Co., Ltd.

- Contact nameAndrew ji Chat Now

- Phone86-539-3116003

- AddressDazhuang Economic & Developing Zone, Yinan County, Shandong, Linyi, Shandong

Product Categories

New Products

-

Autoclave Aerated Brick Making Machinery Price

-

AAC Brick Making Machine ,AAC Concrete Block Machine

-

AAC Light Weight Concrete Block Making Machine in Iraq

-

Ytong AAC Flyash Brick Making Machine Factory in Singpore

-

Hebel AAC Sand Brick Making Machine in Iran

-

Hebel Design AAC Light Weight Block Machine

-

Ytong Germany Design AAC Brick Making Machine

-

Hebel Germany Design AAC Brick Making Machine in Thailand

-

Shandong Capacity 200000m3/year AAC Block Making Machine

-

AAC Brick Production Line Land Require

-

Autoclave Aerated Concrete Brick Machine Factory Cost

-

Ytong Technical AAC Light Weight Block Machine Price

-

Hebel AAC Light Weight Brick Machine Factory in China

-

Hess AAC Block Making Machine in Iraq AAC Block Factory

-

Hess AAC Light Weight Block Machine in Philippine

-

AAC Ligth Weight Brick Machine in Iraq Price

-

AAC Light Weight Block Production Line Price in India Office

-

AAC Block Production Line Price in Myanmar Office

Popular Searches

- sand making machine

- sand making production line

- building model making

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- asphalt concrete mixer

- mobile asphalt mixer

- asphalt bitumen mixer

- asphalt mixer plant

- vehicle equipment

- paver

- making machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- asphalt drum plant bitumen

- double drum

- brick making machinery

- block machine

Recommended Products

- AAC Block Production Line Turnkey Project Service: 50,000-300,000 Cubic Meters AAC Production Line Full Process Solution

- Aerated Concrete Production Line Ball Mill: Aerated Concrete Block Plant Raw Material Grinding

- The Autoclave: The Core of an AAC Aerated Block Production Line

- AAC Block Cutting Machine: Precision Core for Autoclaved Aerated Concrete Production Lines

- AAC Aerated Block Production Line, Autoclaved Aerated Concrete Block Equipment Price

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker With Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Andrew ji

Hi there! Welcome to my shop. Let me know if you have any questions.

Andrew ji

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile