Home > Products > New Products > Stone Production Line,stone crusher plant,stone crushing plant

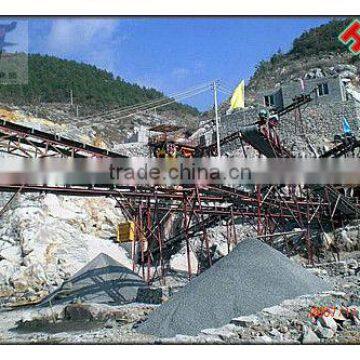

Stone Production Line,stone crusher plant,stone crushing plant

- Qingdao or Shangshanghai

- T/T

You May Like

-

2013circular vibrator mechanical screen used for seperate stone

-

2013circular vibration screen used for seperate stone

-

Disk feeder for mineral processing

-

Best quality shaving bed sorting ores,tungsten,tin,niobium,maganese,chromium titanium,lead,zinc,gold,hematite,brown iron

-

PCL-Sand making machine/sand maker

-

PCL Sand making machine of the best one

Product Details

| Place of Origin | Henan, China | Brand Name | Tengfei | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

Stone production line1. High automaticity

2. High production efficiency,low run cost,big output, high income

3. ISO9001

We manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, electric control, etc. We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments also matching cone crusher, de-duster, etc if necessary to satisfy different customers’ technological requirements. It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' different demands according to different craft requirements.

Process of the Production Line:

Big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing, then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen, and separated to different sizes. Those aggregate with suitable size will be transferred to the final product pile and those with unsuitable size will be transferred to the impact crusher for re-crushing. This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the deduster will be attached for the sake of environment protection.

Characteristics of Stone Production Line:

1. High automaticity, besides to equipment's starting engine off and the routine maintenance, the entire strip production line does not need the manual control nearly.

2. High production efficiency,low run cost,big output, high income, the end product gravel granularity is even, the grain shape is good,which can meets the national high speed needed materials requirement.

3. The stone material production line's equipment disposition is mainly determined based on the customer to the stone material specification as well as the output and the stone material use.

4. We provide pre-sale, sell, the post-sale comprehensive service, produces the scene based on the customer to dispose the flow, makes every effort to achieve the most reasonable, the most economical production line for the customer.

5. Has the advanced electrically controlled operating system, had guaranteed the entire flow leaves the material to be unobstructed, the movement is reliable, the ease of operation, conserves energy.

6. The maintenance of equipment maintenance is simple, vulnerable uses the present newest anti-friction material of home, loses is small, the service life is long, can bring considerable economic efficiency for the customer.

7. The stave product assumes the cube shape, granularity to be even, the grain shape is good, in the needle laminated shape content is low, no crack, does presses the intensity to be high.

8. It has the area to be small, the investment economic efficiency is high, the broken stone material quality is good, stone powder yield rate low status characteristic.

Parameters of Stone Production Line:

No | Max feed opening (mm) | capacity(t/h) | Model | |||||

Vibrating Feeder | Jaw Crusher | Impact Crusher | Vibrating Screen | Belt Conveyor(m) | motor power(kw) | |||

1 | 340 | 30 | GZD2511(3kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1236 (15kw) | 60-90(20kw) | 120 |

2 | 340 | 50 | GZD3117(10kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 |

3 | 420 | 80 | GZD3617(10kw) | PE500×750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 |

4 | 480 | 100 | GZD4321(13kw) | PE600×900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 |

5 | 560 | 150 | GZD4321(13kw) | PE750×1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 |

6 | 630 | 200 | GZD4321(13kw) | PE900×1060(110kw) | PFB1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 |

7 | 630 | 250 | GZD5027(17kw) | PE900×1060(110kw) | PFB1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 |

8 | 630 | 300 | GZD5027(17kw) | PE900×1200(110kw) | PFB1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 |

9 | 700 | 350 | GZD5027(17kw) | PE1000×1200(132kw) | PFB1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 |

10 | 700 | 450 | GZD6223(28kw) | PE1000×1200(132kw) | PFB1214/2(300kw) | 3YZ2145/2 (60kw) | 350(60kw) | 600 |

Contact Us

- Henan Teng Fei Machine Manufacturing Co., Ltd.

- Contact nameSunny Qin Chat Now

- Phone0086-371-67103656

- AddressXintian Street, Xushui Town, Zhongyuan District, Zhengzhou, Henan

Product Categories

New Products

-

PCL Sand making machine for sale with ISO certificate

-

PCL Sand maker with ISO certificate for sale

-

Large-- Hammer Mills for sale

-

Steel Slag Crushing Plant Complete manufacturer

-

Vibrating feeder

-

Top quality Hierarchical machine for sale

-

Professional supplier of Circular vibrating screen

-

GX series High efficient sand washing machine

-

Spring spindle breaker of Tengfei Brand for sale

-

Best-selling Spring type gyratory crusher of Tengfei Brand

-

Best-selling Spring type gyratory crusher of Tengfei Brand

-

2013 the lastest vibrating feeder used for construction

Popular Searches

- wall board machine

- pile concrete

- concrete form machine

- Button Heading Machine

- eps panel line

- laminate plant

- leca production line

- pre machines

- product postings

- products postings

- precast prestress concrete

- purling machine

- precast hollow core slab

- roof pannel

- sale installer

- sales installer

- drawer slides roll forming machine

- automatic rock

- brand installer

- board machin

- board equipements

- corrugate asbestos

- light expanded clay aggregate

- discontinuous pu line

- eps coating

- factory installer

- line panel

- brown fullness machine

- grage

- line shelves

Recommended Products

- Mineral Stone Basalt Panel Making Machine Stone wool Production Line Natural Gas Basalt Rock Wool Making Machine

- gypsum board laminating machine gypsum tiles making machine

- rock wool making machine rock wool machine stone wool making machine

- stone wool production line mineral wool production line rock wool production line

- pur/pvc laminated hot glue press machine pur foil laminating machine pur 1300 lamination machine

- small floor mgo board production line board making manufacturing machine

- small scale gypsum board lamination machine 600*600 gypsum ceiling tiles making machine

- automatic rock wool production line rock basalt mineral wool production line rock wool line production

- small capacity 60x60 pvc laminated gypsum ceiling tiles board laminating making machine production line

- full automatic gypsum board perforating machine gypsum board punching machine

- Pneumatic spray machine Steel structure special multi-functional high pressure airless spray machine environmental protection and paint saving

- Concrete mixing station machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Board Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sunny Qin

Hi there! Welcome to my shop. Let me know if you have any questions.

Sunny Qin

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile