Home > Products > Bolted-type powder silo > High quality cheap price brick making machine in south africa

High quality cheap price brick making machine in south africa

- Xiamen

- T/T Credit Card

You May Like

-

High quality cheap price malaysia manual interlocking brick making machine

-

New china products for sale handmade brick making machine

-

High quality cheap price manual mud brick making machine

-

Concrete batching plant calibration from online shopping

-

Hot china products hydraulic paving brick making machine

-

manufacturer wholesale ghana brick making machine for sale

Product Details

| Condition | New | Type | Hollow Block Making Machine | |

| Brick Raw Material | Cement | Processing | Brick Production Line | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | as requirement, 40.67m³-900m³ | Place of Origin | Fujian, China | |

| Brand Name | Luwei | Model Number | PG50-1000t | |

| Voltage | as requirement | Power | as requirement | |

| Dimension(L*W*H) | as requirement | Certification | ISO | |

| Warranty | 1 Year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

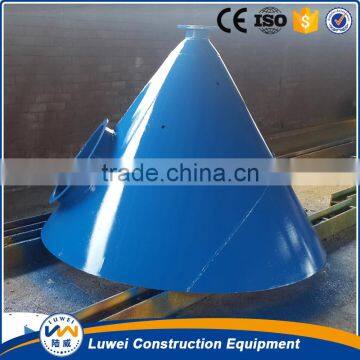

cement storage silos for brick making machine

This kind of silo is to focus on storage of bulk cement, fly ash, and other things mixed agent powder special equipment, and is a kind of supplementary equipment of the concrete mixing station, mixing station buildings and roadbed materials. We also have national patent in Bolted-type Silos (Patent NO: 201020649684.5).This kind of silo enjoys high reputation for easy transportation, installation and dismantlement.

Professional data calculated by TJU (Tongji University)

All the data of silos is provided by TJU, it considers strength of silo, resistance coefficient of the typhoon and bending resistance coefficient.

Manufactured Technology of Cement Silo

The parts of the cement silos are manufactured by special cutting and drilling technologies and they are implemented by special surface cleaning procedure. The parts of the cement silos also are manufactured in sensitive production facilities with special equipments and they are painted with prime coating and final coating.

Super fast production delivery method

1. The silo is in standard modular manufacture and can be freely separated or combined. The product is in reasonable design and easy adjustment. The short production cycle can be significantly shortened the delivery cycle. Most parts of standard products have the stock order, so we can make zero delivery time.

2. All the manufacturing process are in our factory, so the installation time on the construction site is brief. You just need to assemble the parts of silos when you buy it.

Reliable seal structure

1. The compaction degree of special sealing strip is from 5 mm to 1 mm. The strong elasticity effect fill in the full of all possible apertures after the screw bolts are fastened. It can withstand 200 degree heat. Even in the field environment, it can maintain long-term sealing effectiveness.

2. It will leave some tiny gap after condensing the special sealing strips. However, our silo has the clever design which has the perfect sealing affection: when the materials are input to the silo for the first time, the fine dust of material will automatically drill into the gap.

3. The liquid glue is placed outside the special sealing strip; it will extend the service life of the article seal and prevent long time moisture infiltration in the rainy season.

Transportation Program

1. All parts of silos can be packed into bundles with short loading time and little space.

2. The silos can be transported regardless of size. It can greatly reduce the transportation cost because more than one silo may be carried by one truck or container.

3. Bolted-type silos are easily packed into container to the world and it no longer uses the conventional way of break-bulk cargo transportation.

Transportation methods

Type of shipping: flat-bed trailer for domestic market; container for international market. (Type of shipping just for reference, not include accessories)

Easy assembly of bolted-type powder silo

Standard components, efficient and safe construction (with English and Chinese installation)

Installation schedule (for reference)

Technical index (just for reference)

Serial number | Model and size | Diameter (mm) | Number of layers |

Leg distance (mm) | Theoretical capacity (M3) |

1 | PG50T | 3100 | 3 | 2020 | 40.67 |

2 | PG60T | 3100 | 4 | 2020 | 52.13 |

3 | PG100T | 3100 | 7 | 2020 | 86.52 |

4 | PG150T | 3300/3800 | 6/8 | 2180/2570 | 111.74/114.96 |

5 | PG200T | 4500 | 6 | 3010 | 164.27 |

6 | PG300T | 5000 | 7 | 3290 | 234.85 |

7 | PG400T | 5700 | 8 | 2640 | 348.14 |

8 | PG500T | 6500 | 8 | 3015 | 458.36 |

9 | PG800T | 8000 | 8 | 3660 | 700 |

Note: The above sizes are just for reference. We can design and manufacture according to the fact condition as well as the clients’ requirements.

Luwei company is a professional manufacturer in producing bolted-type silo, which has it own national patent certificate for ‘Bolted-type Powder Silos’ (Patent No.201020649684.5). It covers an area of 8000 square meter which integrates research, development, manufacture and sales into a whole. It can supply 100 sets of silos every month. The annual sales value reaches five million dollars.

Luwei bolted-type silo is used for storing bulk materials such as cement, powder, lime, gypsum, fly ash, different binder materials, gravel, limestone, sand and different chippings. Luwei bolted-type silo is mainly used in many areas, such as construction material, chemical engineering, energy resources, environmental protection and foodstuff, like loading and unloading plants, dosing-weighing and mixing plants, batching plant etc.

Contact Us

- Xiamen Luwei Construction Equipment Co., Ltd.

- Contact nameTina Ye Chat Now

- Phone86-592-7072928

- AddressNo.12-24 LongXin Road, XinXU Town XiangAn District, Xiamen, Xiamen, Fujian

Product Categories

New Products

-

high quality customized steel silos in cement production line

-

price of the cement silo in cement block making machine

-

hot sale steel silo with cement silo foundation from cement silo manufacturer

-

60 m3 steel cement silo in concrete mixing plant

-

50-2000 ton steel coal silo in concrete batching plant

-

Competitive price silo machine steel cement silo for sale

-

Competitive price portable concrete cement silo in cement plant

-

Cement steel silo for cement terminal cement factory

-

High steel cement silo in concrete batching plant cost

-

2016 hot sale 800ton mobile cement silo price

-

Cement silo hot sale steel silo 200ton cement silo price

-

Cement silo used steel silo buy direct from china manufacturer

-

Durable cement silo tank for sale

-

Competitive price cement storage bin steel silo for sale

-

Wholesale cement mixer silo concrete silos for sale

-

Small concrete mixer/used cement mixer most selling product in

-

Rmc plant/cement company new products on china market 2016

-

2016 new product on china market grain storage bins for sale

-

Hot product cheap cement mixer truck/concrete silo for sale

-

New product launch concrete mixer truck/cement mixer truck

-

China manufacturer wholesale grain bin house/grain handling

-

New products on china market grain silo house/small grain bins

-

New products on china market grain silos/grain bins for sale

-

manufacturer wholesale grain handling/steel grain bins

Popular Searches

- Sand Making Machine

- Sand Making Production Line

- building model making

- Asphalt Mixers

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- Asphalt Concrete Mixer

- Mobile Asphalt Mixer

- Asphalt Bitumen Mixer

- Asphalt Mixer Plant

- vehicle equipment

- paver

- Making Machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- Asphalt Drum Plant Bitumen

- double drum

- Brick Making Machinery

Recommended Products

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker with Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tina Ye

Hi there! Welcome to my shop. Let me know if you have any questions.

Tina Ye

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile