Home > Products > rotary kiln > High-tech coal natural gas based energy saving mini kiln

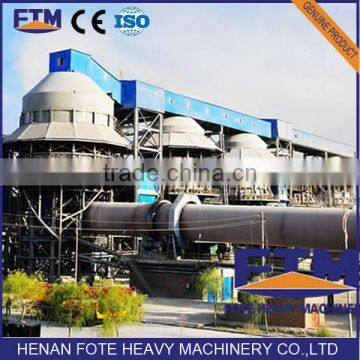

High-tech coal natural gas based energy saving mini kiln

- Shanghai/Qingdao/Tianjin Port

- T/T

You May Like

Product Details

| Condition | New | Production Capacity | 150-1000t/d | |

| Place of Origin | Henan, China | Brand Name | FTM | |

| Model Number | Variety type | Voltage | 380v | |

| Power(W) | 30-420kw | Dimension(L*W*H) | multy type as per | |

| Weight | 53-598.5tons | Certification | CE&ISO | |

| Warranty | 1 year, 1 year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

mini kiln1.Low heat consumption:20%

2.Stable & Reliable working condition

3..CE&ISO

High-tech coal natural gas based energy saving mini kiln

Introduction

1. Rotary kiln have the highest quality, with the widest range of stone feed size.

2. Rotary kiln can use gas, oil or coal for firing. We designs for single line plants up to 1,800 tpd.

Application

Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:

*Cement, *Lime, *Refractories, *Metakaolin, *Titanium dioxide, *Alumina, *Vermiculite, *Iron ore pellets, *Zinc ore pellets.

Workingb Principle

Modern plants are composed of 3 key components to acheive high effiency: Cooler, Kiln, and Preheater.

The basic components of a calcination rotary kiln are the shell, the refractory lining, support tyres and rollers, drive gear and internal heat exchangers.

The calcination rotary kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil or pulverized coal.

Features and Advantages

1. High capacity:150-1000t/d

2. Low heat consumption 20%

3. Excellent clinker quality and stable operation

4. Lower SOx and NOx emissions.

5. Operates on a variety of fuels.

6. Control system for entire facility

7. Wide range of stone feed sizes.

Technical parameters

( Part technical parameters of rotary kiln for your reference)

Company Profile

Henan Fote Heavy Machinery Co., Ltd covers an area of 100,000 square meters which

includes 60,000 square meters of heavy duty workshops. We have more than 200 sets

of large and medium sized metal processing equipments. The Maximum lifting capacity

is 300 tons.

Our service

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export.

3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

Contact Us

- Henan Fote Heavy Machinery Co., Ltd.

- Contact nameTina Liu Chat Now

- Phone0086-371-86106899

- AddressNo.170 Nanyang Rd. Huiji dist. zhengzhou, China , Zhengzhou, Henan

Product Categories

New Products

-

Energy saving 6000t/d clinker rotary kiln

-

Energy saving active lime rotary kiln

-

Energy saving active rotary kiln

-

Energy saving alumina rotary kiln

-

Energy saving bauxite kiln

-

Energy saving lime titanium dioxide lead rotary kiln price

-

Energy saving benefication magnetic separator

-

Energy saving calcination rotary kiln for bauxite

-

Energy saving calcine bauxite rotary kiln machinery

-

Energy saving calcining kiln

-

Energy saving design cement kiln

-

Energy saving design lime kiln

-

Energy saving dolomite calcination rotary kiln

-

Large capacity drum cooling machine

-

Energy saving dry cement kiln

-

China top design dry process cement rotary kiln

-

Energy saving dry process rotary kiln

-

Energy saving drying rotary kiln

-

Energy saving durable rotary kiln

-

China Leading manfacturer directly sell gold-smelting equipment alat pendingin monocular cooler

-

High Efficiency Monocular Cooler Manufacturer for Clinker Cooling

-

Energ saving high capacity ore monocular cooler

-

Energy saving high capacity ore monocular cooler machine

-

High capacity ore monocular cooler machine

Popular Searches

- concrete truck

- active lime kiln

- lime kiln equipment

- industrial lime kiln

- shaft lime kiln

- vertical lime kiln

- rotary kiln

- cement grinding station

- mixer truck

- concrete mixer truck

- rotary kiln machine

- lime kiln

- kiln

- lime rotary kiln

- vertical shaft lime kiln

- rotary kiln activated carbon

- cement kiln

- cement mixer truck

- mixer tank truck

- mixer machine truck

- concrete mixer truck weight

- concrete mixer car

- vertical shaft kiln

- quicklime production line

- quicklime rotary kiln

- transit mixer

- mixer vehicle

- clinker grinding plant

- cement truck

- wall paint spray gun

Recommended Products

- SHANTUI Concrete Pump truck 25m-70m

- Concrete Batching Plant HZS180-5L with Capacity 180m3/h

- High Quality Cement Conveyor Pump Equipment Fine Aggregate Concrete Hydraulic Pumps Concrete Pump Truck

- Water conservancy engineering mixing rod, concrete vibrator, excavator used

- Construction machinery concrete mixer hydraulic vibrator

- Engineering excavator modified vibrating rod concrete vibrating machine

- Concrete vibrating machine excavator modified vibrating rod

- Vibration compaction machine excavator modification z'd'qi

- Construction of concrete mixer, mechanical sliding mixing bucket

- Slip front mixer forklift modification mixing bucket discount

- Slip front mixer forklift modification mixing bucket discount

- Small shovel to mixer head loader hydraulic mixing bucket manufacturer

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Concrete Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tina Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Tina Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile