Home > Products > New Products > European technology potato&Cassava starch production line

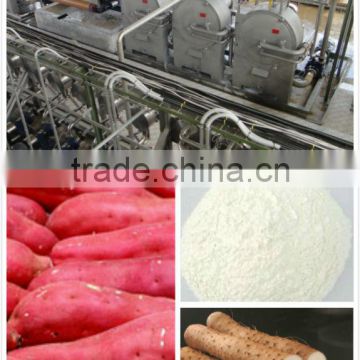

European technology potato&Cassava starch production line

- Shanghai

- T/T

You May Like

Product Details

| Place of Origin | Anhui, China | Brand Name | SGT | |

| Type | Other | After-sales Service Provided | Overseas service center available |

Product Description

Cassava Starch Production Line

More than 10 years experience in tuber starch processing field

Adopting advanced European process technology

Process description: Cassava transporting, De-stoning, Washing, Chopping, Rasping, De-sanding, Fiber extraction, Concentration and refining, De-watering , Drying, Packing

Processing capacity : 20 tons/day Cassava starch 60 tons/day Cassava starch 100 tons/day

Cassava starch Advantages:

- Advanced European process technology

- High quality equipment materials and treatment

- First class machine fabrication technology and strict quality control

- Advanced DCS control system

- First class potato starch quality

- Excellent after sale service

For more details please contact us.

The fresh harvested roots are weighted and storages on a clean concrete square. From there they are dumped into rotary cleaning drums for pre-cleaning/dry cleaning of the roots. The roots coming from the cleaning drums are transported to the paddle washer/peeler. At inspection belt the roots are inspected on tails and remaining impurities such as timber and bones. After inspection the roots are transported to the rasping section. The cleaned roots coming from the root washing section are fed into the chopper. The chopper chops the roots into coarse pieces which fall into the rasping-hopper and then they are dosed and distributed to the rasper. The disintegrated roots are pumped into the desanding units where sand and other coarse particles are removed. The de-sanded root-slurry is discharged to the extraction section. One extraction/pulp-dewatering line consists of one three-stage extraction unit and one pulp-dewatering sieve.The starch milk is discharged to the crude starch milk tank.The fibers from an extraction unit are fed to a pulp-dewatering unit where the fibers are dewatered. Before the crude starch milk is fed to the separator for concentration, a second degritting is executed to remove the very fine sand (red clay) from the starch milk. The crude starch milk is fed into the two phase nozzle separator via the rotary brush strainer to protect the nozzles of the separator for coarse impurities. The crude starch milk is concentrated to a density of 18 - 19° Bé and continuously discharged through the nozzles. The concentrated starch milk is directly fed into the washing unit. The washing unit is a multi stage cyclone unit consists of 8 washing stages. The starch milk is washed counter currently in order to remove the remaining fibers, protein and other impurities. The dewatering is done by a peeler centrifuge. The dewatered starch cake is discharged on a belt conveyor which transports it the dryer section. After dewatering of the starch milk, the starch cake is transported by belt conveyors to the flash dryer. The refine starch is transported into a starch silo, where the starch is cooled by retention time. From the silo the starch is extracted by the semi-automatic bagging installation, where the starch is bagged into 25kg bags.

Main Equipment 1 Paddle washer 2 Rasper 3 Desanding unit 4 Centrisieve 5 Dewatering sieve 6 Hydrocyclone unit 7 Fine fibre sieve 8 Peeler centrifuge 9 Flash dryer 10 Weighing and packing machine 11 Control system 12 Miscellaneous

Our company homepage: /

Contact Us

- Sino-German Technology Development Co., Ltd.

- Contact nameSGT Tidecom Chat Now

- Phone86-10-58672506

- AddressRoom 302, Unit E, No. 3 Building, Luozhuang Hongjiali Park

Product Categories

New Products

-

China Tapioca starch processing equipment & Vacuum Filter

-

Wheat Starch Processing Line with outstanding starch drier

-

Potato/ cassava starch process equipment Extractor with conical screen for separation of starch from fiber

-

Modified starch making machine in China

-

Corn Starch manufacturers machine

-

Hot Sale Potato Tapioca Cassava Corn Modified Starch Machine

-

2014 The most popular Glucose syrup production line

-

Atlantic Potato for Fries

-

cassava starch extracting machine

-

Field managing machine ( Back rotary tillage )

-

Corn thresher

-

Stainless Steel Food Processing Machine Potato Peeling Machine

Popular Searches

- electric grinder

- separating machine

- color sorter

- color sorter machine

- kitchen equipment

- color sorting machine

- food dehydrator

- nut sorting grading machine

- automatic drying oven

- belt color sorter

- nut color sorter

- vegetable slicer

- dicer

- sorter machine

- sorting machine

- beater

- vegetable cutter slicer

- meat slicer

- meat slicing machine slicer

- vegetable cutter

- fruit sorting machine

- bean sorting machine

- dehydrator

- meat mincer

- electric meat grinder

- meat grinder

- fish food processing machine

- fresh machine

- pepper chili seed

- fresh sesame

Recommended Products

- Smart Fish Grilling Oven - Restaurant Grade, Saves Energy & Labor Costs

- 200–300 kg/h Feed Pellet Machine for Small-Scale Production

- Automatic Steam/Electric/Gas Jacketed Cooking Kettle/Cooking Pot with Mixer/Agitator for Sauce Curry Paste

- Build a Smarter Aquafeed Plant with Kawise Extruder Feed Machine

- 1T/H Feed Pellet Production Solution from Kawise Machinery

- Pellet Die Size & Machine Selection Guide

- Maximize Feed Efficiency with Kawise Small Feed Pellet Machine

- Efficient 200-300kg/h Feed Pellet Line for Your Business

- High-Efficiency 300-400KG/H Feed Pellet Machine

- Feed Pellet Machine: The Perfect Solution for Livestock and Poultry Feed Production

- Commercial | Industrial Peanut Butter Machine

- Automatic Coffee bean color sorting machine Bean color sorter

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machinery for Food, Beverage & Cereal > Pet Food Processing Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

SGT Tidecom

Hi there! Welcome to my shop. Let me know if you have any questions.

SGT Tidecom

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile