Home > Products > Multistage Hydrocyclone Unit > Multi-stage hydrocyclones, potato/ cassava/ corn starch process equipment

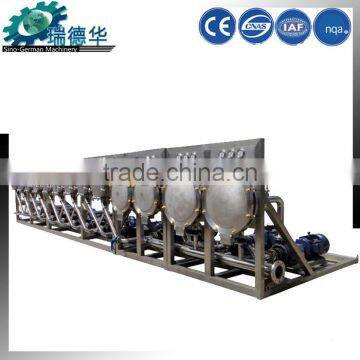

Multi-stage hydrocyclones, potato/ cassava/ corn starch process equipment

- PORT OF SHANGHAI

- T/T L/C Credit Card PayPal

You May Like

-

Multi-hydrocyclones key processing machine of starch production line suitable for starch milk rinsing

-

China automatic healthy modified starch making machine

-

starch Hydrocyclone manufacturer

-

Stainless Steel corn starch production line from China -Multistage Hydrocyclone Unit

-

automatic potato/cassava/corn/sweet potato/pea chips making machine

-

Automatic Potato chips making machine

Product Details

| Condition | New | Type | Other, satrch production machine | |

| Place of Origin | Anhui, China | Brand Name | SGT | |

| Certification | ISO/CE/CCC | Warranty | 12 months | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Multi-stage hydrocyclones, key process machine for starch processing

Working principle

Mutli-stages hydrocyclone is suitable for removing soluble and insoluble foreign matters such as protein, fiber, pectin and etc from starch milk efficiently. By centrifugal force of inflow under high pressure, each conical cyclone works as a separate unit inside the whole block. The working principle is by the centrifugal force heavy phase matter i.e. starch moves down to the bottom of cyclone as underflow thus form an opposite pressure on light phase matters i.e. protein, fiber to move up to the top as overflow. By this mean, starch is purified stage by stage and at the last stage starch milk of 18-22 Baume will be obtained.

Main Function

Fig. I Fig. II

There are two types of hydrocyclone blocks in Multi-hydrocyclones as shown above in Fig. I and Fig. II. Each type is used in different stage along one battery of hydrocyclones.

Fig. I named plate type hydrocyclone is of hygienic type suitable for starch milk full of sticky matters such as pectin. This type features no dead-end and free flow in channel so bacteria can't not stay alive inside the channel, which ensure hygiene standard. Normally this type is used in concentration and recovery stage of Multi-hydrocyclones.

Fig. II named drum type hydrocyclone is used in rinsing stage of Multi-hydrocyclones with good performance. It's suitable for washing less sticky starch milk such as corn starch.

Normally, one battery of hydrocyclones includes the following in sequence:

- 1 stage of concentration hydrocyclone;

- 2 stages of recovery hydrocyclone;

- 9 stages of rinsing hydrocyclone for cassava starch or

12 stages of rinsing hydrocyclone for potato starch (because the fine fiber content is higher in potato starch milk and it is harder to wash starch with fiber)

We can not only provide single equipment or whole processing line, but also supply our clients professional turnkey solutions based on their special needs. And our engineers are available to instruct your installation overseas.

Company Information:

As a sub-company of TTC Group,Sino-German Technology Co.,Ltd is a professional company dedicated to the R&D and manufacturing of food and agricultural products processing lines.

Taking the advantage of closs cooperation with related domestic and international research institutes and experts,the company combines international advanced technology and experience with dometic cost advantages,we supply more cost-effective food and agricultural processing equipments to clients all ove the word.

Exhibition:

FAQ:

1.Q:Are you factory or trading company?

A: We are a group company with factory.

2.Q:where is your factory located?How to visit there?

A: Our factory is located in Hefei City, Anhui Province, China, around 2.5 hours from Shanghai by bullet train. All clients, from domestic or abroad, are warmly welcome to visiting us.

3.Q:How does your machine works?

A: The whole production line works automatically to produce powder from raw material (potato, cassava) under monitoring and control.

4.Q:How can i get some samples?

A: Please send us your enquiries so we can help, though we are not starch plant but machine factory.

5.Q:How does your factory do regarding quality control?

A: "Quality is priority, SGT Machine always attach great importance to quality controlling from the every beginning to the every end.We have survice agents aboard.

HOMEPAGE

Contact Us

- Sino-German Technology Development Co., Ltd.

- Contact nameSGT Tidecom Chat Now

- Phone86-10-58672506

- AddressRoom 302, Unit E, No. 3 Building, Luozhuang Hongjiali Park

Product Categories

New Products

-

potato flakes production line

-

Steel potato flakes production line

-

Potato granules production line

-

200kgh/ 300kg/h semi-automatic/automatic potato chips making machine

-

High efficiency hot sale potato chips production line

-

300kgh semi-automatic/automatic potato chips making machine

-

complete Pringles potato chips making machine

-

high quality potato chips making machine/French fries production line/potato chips production line

-

hot-selling potato chips making machine

-

automatic potato/cassava/corn/sweet potato/pea chips making machine

-

SGT sino-german automatic small scale potato chips production line /processing line

-

Hot selling Potato chips making machine

-

Automatic Potato chips making machine

-

Potato chips making machine

-

high efficient stainless steel fried potato chips production equipment

-

European newest technology automatic cassava and potato starch production line

-

SGTadvanced potato starch processing line for sale

-

rice starch/vermicelli processing equipment

-

Potato starch processing machine

-

15ton per hour free training potato starch production line

-

2015 hot sale potato starch making machine/ cassava starch making machine

-

15ton per hour free training potato starch production line

-

potato/cassava/tapioca/yam starch making machine desanding cyclone

-

15ton per hour free training potato starch production line

Popular Searches

- automatic home chapati making machine

- anko food machine

- samosa machine canada

- samosa machine usa

- df28 dumpling machine

- curry puff maker

- compact tortilla maker

- steamed bun maker

- electric noodle machine

- nepal momo making machine

- dried noodle machine

- bread crumbs extruder

- bag dumpling

- china momo

- high automatization 2012

- imperia pasta machine

- jgl120 samosa machine

- mie

- noddle making machine

- plastic dumpling press

- roti press

- sales automat 2012

- steamed filling bun machine

- sponge hair bun maker

- dough flatten machine

- gari frying machine

- home wonton wrapper machine

- fo shan

- indian samosa machine

- samosa making machine uk

Recommended Products

- Dumpling/Pie Machine for different shapes dumpling production Industry/Family Use Dumpling Maker

- Dumpling Machine for different shapes dumpling production Industry/Family Use Pie Machine Automatic Samosa Making Machine Dumpling Maker

- Automatic Wafer Cup Forming Machine Wafer Cone Making Machine

- Fully Automatic Sugar Cone Production Line, Ice Cream Waffle Cone Processing line 3000-7000pcs/h

- Fully Automatic pring Roll Line Meat Roll Production Line Egg Roll Production line to USA

- Mesin pembuat mutiara tapioka Taiwan FY-006, boba tapioka Sabudana (Sagu) di dalam pabrik

- FY-006 Тайваньская машина для производства жемчуга из тапиоки, Sabudana (Sago) тапиока боба внутри фабрики

- South Korea Samosa Making Machine Shrimp Dumpling Machine

- Pizza Dough Cutter Dough Divider Rounder Automatic Dough Dividers

- Automatic Dumping Making Machine Samosa Making Machine Empanada Maker Ravioli Forming Machine

- Automatic Efficient Pizza Base Forming Machine for Kitchen Pizza Base Maker Pressing Machine

- Automatic Donut Making Machine Yeast Donut Maker Donut Fryer Ring Donut Forming Machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Machinery for Food, Beverage & Cereal > Grain Products Processing Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

SGT Tidecom

Hi there! Welcome to my shop. Let me know if you have any questions.

SGT Tidecom

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile