Home > Products > PVC/TPE/TPU PP Resin, master batch > LOI>100 Fire resistant fireproof Ceramic Polyethylene cable resin for cable

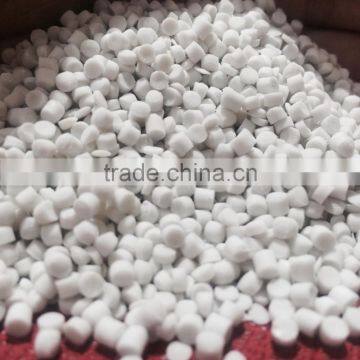

LOI>100 Fire resistant fireproof Ceramic Polyethylene cable resin for cable

- 200 Ton / Tons per Month

- SHENZHEN

- T/T

You May Like

-

data wire insulation & jacket TPE

-

Fire resistant fireproof Ceramic cable rubber resin with Heat Resistance 900

-

halogen free flame retardant TPE granules for plugs and connectors

-

halogen free flame retardant TPE

-

Ceramic fire-retardant polyolefin material for cable

-

Ceramifiable polyolefin insulation compound for low voltage cable

Product Details

| CAS No. | 9002-86-2 | Other Names | Fire resistant fireproof Ceramic polyolefin resin | |

| MF | None | EINECS No. | 208-750-2 | |

| Place of Origin | Jiangxi, China | Type | Synthetic Resin and Plastics | |

| Brand Name | anshi | Model Number | all type | |

| Purity | 100% |

Product Description

Fire resistant fireproof Ceramic polyolefin materials

Fire resistant ceramic polyolefin materials for low voltage cables

1.Type and application

Type | Product | Application |

TJY5121 | Ceramifiable POE insulation compound for low voltage cable | Flame retardant and Fire retardant low voltage cable |

THT3093 | Ceramifiable POE sheath compound for low voltage cable | Flame retardant and Fire retardant low voltage cable |

TG1101 | Ceramifiable POE oxygen-barrier compound for low voltage cable | Flame retardant and Fire retardant low voltage cable |

2. Product description

Ceramifiable, Flame retardant and Fire retardant POE compound for low voltage cable is based on POE resin, produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing technic

The compound can be processed with conventional extruder, and the screw with a minimum 20:1

L/D and a compression ratio of 1.2~1.5 is recommended.

The following temperature profile of extruder is recommended:

Heat Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 150 | 160 | 170 | 170 | 175 | 175 |

Note: Compound should be dried at 70-80℃ before use, which has storage time exceeding two months.

4. Storage and transport

Packaging: 25kg/bag, Aluminum foil and PE membrane inside bag, and kraft paper outside bag.

Storage and transport: Avoiding in direct basked and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties

Item | Uint | Standard | TJY5121 | THT3093 | TG1101 |

Typical | Typical | Typical | |||

Density | g/cm3 | -- | 1.54 | 1.54 | 1.55 |

Hardness | Shore A/D | -- | 92/40 | 94/42 | 94/40 |

Tensile Strength | ≥MPa | 6 | 8.65 | 7.5 | 8.65 |

Elongation at break | ≥% | 100 | 152 | 162 | 110 |

Thermal Aging | ℃*h |

| 100*240 | ||

Tensile Strength | ≥MPa | 6 | 9.5 | 7.3 | -- |

TS Change rate | ≤% | ±30 | +10 | -3 | -- |

Elongation at break | ≥% | 70 | 138 | 145 | -- |

EB Change rate | ≤% | ±30 | -10 | -11 | -- |

Volume Resistivity,at | ≥Ω•m | 1.0*1010 | 3.8*1014 | 3.7*1013 | 3.3*1013 |

Dielectric Strength | ≥Mv/m | 18 | 28 | 27 | 24 |

Impact Brittleness Temperature | ≤ |

| -45 | -45 | -45 |

15/30 | 0/30 | 0/30 | 0/30 | ||

Smoke Density |

|

| GB/T 8323 | ||

Flaming | ≤ | 100 | 60 | 55 | 44 |

Non flaming | ≤ | 250 | 144 | 160 | 108 |

Acidity of gases evolve | (PH)≥ | 4.3 | 6.5 | 6.2 | 6.3 |

Conductivity of gases evolved | ≤μs/mm | 10 | 1.0 | 0.5 | 0.5 |

Content of halogen acids | ≤mg/g | 5 | 0 | 0 | 0 |

Toxicity | ≤ | 2.5 | 0.3 | 0.2 | 0.6 |

environmental stress crack resistance | ≥96h | pass | pass | pass | pass |

thermal stress crack resistance | ≥96h | pass | pass | pass | pass |

Burn Properties | |||||

bending strength | ≥MPa | -- | 5.9 | 10.5 | 9.2 |

Volume Resistivity | ≥Ω•m | -- | ≥2.0*1018 | ≥2.0*1018 | ≥2.0*1018 |

Dielectric Strength | ≥Mv/m | -- | ≥40 | ≥40 | ≥40 |

ceramic retention | ≥% | -- | 80.2 | 84 | 85 |

Fire resistant ceramic polyolefin materials for medium voltage cables

2, Type and application

Type | Product | Application |

TJY5201 | Ceramifiable POE insulation compound for medium voltage cable | Flame retardant and Fire retardant medium voltage cable |

THT3254 | Ceramifiable POE sheath compound for medium voltage cable | Flame retardant and Fire retardant medium voltage cable |

TG1106 | Ceramifiable POE oxygen-barrier compound for medium voltage cable | Flame retardant and Fire retardant medium voltage cable |

2, Product description

Ceramifiable, Flame retardant and Fire retardant POE compound for medium voltage cable is based on POE resin, produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3, Processing technic

The compound can be processed with conventional extruder, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2~1.5 is recommended.

The following temperature profile of extruder is recommended:

Heat Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 150 | 160 | 170 | 170 | 175 | 175 |

Note: Compound should be dried at 70-80℃ before use, which has storage time exceeding two months.

4, Storage and transport

Packaging: 25kg/bag, Aluminum foil and PE membrane inside bag, and kraft paper outside bag.

Storage and transport: Avoiding in direct basked and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5, Properties

Item |

Uint |

Standard | TJY5201 | THT3254 | TG1106 |

Typical | Typical | Typical | |||

Density | g/cm3 | -- | 1.48 | 1.46 | 1.58 |

Hardness | Shore A/D | -- | 95/52 | 95/50 | 95/52 |

Tensile Strength | ≥MPa | 6 | 12.2 | 11.7 | 10.6 |

Elongation at break | ≥% | 100 | 218 | 240 | 75 |

Thermal Aging | ℃*h |

| 100*240 | ||

Tensile Strength | ≥MPa | 6 | 13.8 | 13.0 | -- |

TS Change rate | ≤% | ±30 | +13 | +11 | -- |

Elongation at break | ≥% | 70 | 203 | 219 | -- |

EB Change rate | ≤% | ±30 | -7 | -9 | -- |

Volume Resistivity,at | ≥Ω•m | 1.0*1010 | 3.8*1014 | 2.8*1013 | 2.0*1014 |

Dielectric Strength | ≥Mv/m | 18 | 28 | 26 | 26 |

Impact Brittleness Temperature | ≤ |

| -65 | -45 | -45 |

15/30 | 0/30 | 0/30 | 0/30 | ||

Smoke Density |

|

| GB/T 8323 | ||

Flaming | ≤ | 100 | 51 | 52 | 40 |

Non flaming | ≤ | 250 | 149 | 151 | 110 |

Acidity of gases evolve | (PH)≥ | 4.3 | 6.6 | 6.4 | 6.4 |

Conductivity of gases evolved | ≤μs/mm | 10 | 1.0 | 0.5 | 0.5 |

Content of halogen acids | ≤mg/g | 5 | 0 | 0 | 0 |

Toxicity | ≤ | 2.5 | 0.3 | 0.5 | 0.6 |

environmental stress crack resistance | ≥96h | pass | pass | pass | pass |

thermal stress crack resistance | ≥96h | pass | pass | pass | pass |

Burn Properties | |||||

bending strength | ≥MPa | -- | 5.9 | 9.8 | 8.9 |

Volume Resistivity | ≥Ω•m | -- | ≥2.0*1018 | ≥2.0*1018 | ≥2.0*1018 |

Dielectric Strength | ≥Mv/m | -- | ≥40 | ≥40 | ≥40 |

ceramic retention | ≥% | -- | 80.2 | 82.9 | 79 |

Excellent safety and Eco-friendly:

Flame-retardant, no dripping, smoke toxicityto grade ZA1, namely there is no difference after three days once mice inhaled 30mins. so it will not cause secondary damage to the human body; smoke density light transmittance rate of up to 80% above; halogen free, non-toxic, non taste, no heavy metals for raw materials, exceed ROSH standards;

Economy:

Low density, low price, can replace the flexible fire resistant cables insulation and fire-resistant layer ,can solve welding problem of TIG burn insulation, the use of insulation and oxygen barrier for aluminum sheathed fire resistant cables. Process simple, cost and efficiency far superior to mica tape, ceramic composite tape and ceramic silicone rubber, the best solution for the flexible fire resistant cable and aluminum sheathed fireproof fire-resistant cable.

Application:

High, medium and low voltage wire and cable fire-resistant, flexible fireproof cable, fireproof power and control cables, mining cables, marine cables, oilfield and offshore platform fireproof cables, fireproof instrumentation cables, fireproof signals and data cables, fireproof coaxial cables, fireproof fiber optic cables, automotive wires, home improvement wires.

Contact Us

- Jiangxi Longtai New Material Co., Ltd.

Product Categories

New Products

-

Ceramifiable polyolefin insulation granule for low voltage cable

-

ceramic fire-retardant polyolefin insulation granule for low voltage cable

-

ceramic fire-retardant polyolefin insulation material

-

halogen free flame retardant TPE resin for wire cable

-

halogen free flame retardant wire cable TPE for apple

-

ceramic fire-retardant polyolefin granule---low voltage cable

-

ceramic fire-retardant polyolefin granule---medium voltage cable

-

ceramic fire-retardant polyolefin material---medium voltage cable

-

ceramic fire-retardant polyolefin material for medium voltage cable

-

ceramic fire-retardant polyolefin material from Longtai

-

halogen free flame retardant TPE for wire and cable

-

ceramic fire-retardant new material--polyolefin

-

hot sale ceramic fire-retardant new material--polyolefin

-

TPE granules for charging-pile cable

-

high quality ceramic fire-retardant new material--polyolefin

-

Ceramifiable POE insulation compound for medium voltage cable

-

Ceramifiable POE insulation material for medium voltage cable

-

Ceramifiable POE insulation granule for medium voltage cable

Popular Searches

- masterbatch

- Flame Retardant Masterbatch

- Calcium Masterbatch

- plastic masterbatch

- container desiccant bag

- color masterbatch

- Lightweight Eva

- Foam Roll Eva

- black masterbatch

- masterbatch color

- white masterbatch

- caco3 filler masterbatch

- filler masterbatch

- plastic red masterbatch

- masterbatch filler

- Plastic Masterbatches

- Plastic Color Masterbatch

- Black Color Masterbatch

- Plastic Filler Masterbatch

- Blue Masterbatch

- Red Masterbatch

- Pet Raw Material

- Pvc Raw Material

- pom plastic

- Master Batch Pp

- master batch

- Rubber Masterbatches

- Master Batch Compound

- tpu material

- Abs Plastic Sheet

Recommended Products

- Nickel Extraction Material

- Molybdenum recycling materials

- Recovery of gallium resin from mother liquor in Bayer process

- Silver recovery resin

- Rare earth metal extraction resin

- resina de extracción de cobalto

- Silver recovery resin

- Lithium adsorbent for Directly Lithium Extraction

- Silicon removal from photovoltaic wastewater

- Recycling nickel, cobalt and manganese from waste ternary lithium battery

- Hexavalent Chromium Removal Materials

- Hexavalent Chromium Removal Materials

Find Similar Products By Category

- Chemicals > Plastic & Polymer > Polymer & Resin

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile