Home > Products > New Products > Expansion Refrigeration Process

Expansion Refrigeration Process

You May Like

Product Description

Specifications

The expansion refrigeration process, characterized by simple configuration, low investment, quick start, easy operation, good ad

Company Profile

ZhuHai GongTong Low Carbon Technology Co., Ltd.,located in ZhuHai City(a special zone of reforming and opening),Guangdong Province,is a professional corporation of designing and manufacturing complete equipments for gas separation,purification,liquefaction and storage.The conpamy has deep research and extensive practice in adsorption and rectification process,equipment and automatic control etc. Main products include CO2 Recovery Plant,LNG Liqudfaction Plant, Air Separation Plant,Cryogenic Liquid Storage & Transportation System etc. We can customizedly designed according to actual requirements of users.

Besides self scientific research system and manufacture system, the company owns import-export license. The company has obtained the ISO 9001 Quality System Certificate by QA Corporation in Britain, the U Stamp certificate Authorized by American Society of Mechanical Engineer(ASME),and certificate of design, manufacture,and installation for Grade 1,2,3 pressure vessels awarded by General Administration of Quality Supervision, Inspection and Quarantine of People’s Republic of China.

Company Qualification

Manufacture License of Type Three Low Pressure,Medium Pressure and High Pressure cessel authorized by AQSIQ(State Adminstration for Quality Supervision and Inspection and Quarantine)with capacity of manufacturing pressure vessels of design pressure 0~100MPa.

Design License of Type Three Low Pressure and Medium Pressure Vessel authorized by AQSIQ(State Adminstration for Quality Supervision and Inspection and Quarantine)with capacity of manufacturing pressure vessels of design pressure 0~10.0MPa.

“NB”Stamp Manufacture Certificate authorized by American Society of Mechanical Engineer(ASME)

“U”Stamp Manufacture Certificate authorized by American Society of Mechanical Engineer(ASME)

GC1 Grade Industrial Pipeline Installation,Alteration,Repair & Maintenance License authorized by AQSIQ(State Adminstration for Quality Supervision and Inspection and Quarantine)

ISO9001:2008 Quality System Certificate authorized by QA corporation in Britain.

UL Certificate for “Underground Flammable-Liquid Tank”authorized by Underwriters Laboratories.

National patent of invention:“Hydrocarbon Removal Technology of Carbon Dioxide”

Credentials of Non-governmental-run Manufacturing Science and Technology Enterprise authorized by Zhuhai Science & Technology Bureau

Our self designed and manufactured automatic CO2 purification and liquefaction equipment has been authenticated by CCIEA

Member of China Chemical Industry Equipment Association(CCIEA)

National High-tech Enterprise Certificate authorized by Guangdong Science and Technology Department.

Our company is the teaching practise base for Beijin Institute of Technology.

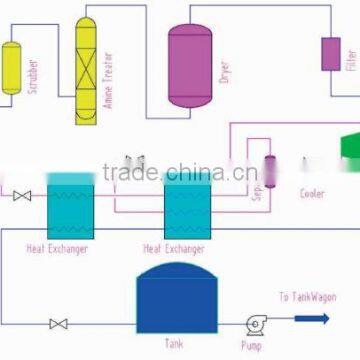

The expansion refrigeration process, characterized by simple configuration, low investment, quick start, easy operation, good adaptability and energy-saving for natural gas expansion by taking advantage of pipe pressure differences, is widely used in small and medium-sized LNG plants.

Expander refrigeration cycle(basing on various types of refrigerants, it can be classfied in nitrogen expander refrigeration cycle, N-CH4 expander refrigeration cycle and natural gas expander refrigeration cycle)is to achieve liquefaction of natural gas by the use of Claude cycle refrigeration through high-pressure refrigerant adiabatic expansion in turbo expander.

After being compressed in refrigerant compressor, refrigerant is supercharged by expander supercharging side. Then it goes into liquefaction heat exchanger for cooling. Before reheating and entering into refrigerant compressor, refrigerant expands in expander and returns to liquefaction heat exchanger to provide cold energy. Refrigeration cycle forms through this process.

In order to lower energy consumption of expander liquefaction process, an ammonia-freon-propane precooling cycle is added at the high temperature section of the liquefation heat exchanger.

Full-range of service

The combination of eight key elements is Process Design,Equipment Design,Automatic Control System Design,Manufacture, Engineering Design,Installation,Commissioning & Training, After-sales Service,providing the company with the ability of undertaking turnkey projects independently.

Contact Us

- Zhuhai GongTong Low Carbon Technology Co., Ltd.

- Contact nameJiang Wu Chat Now

- Phone0086-756-7799311

- AddressHongQi Center industrial park,JinWan District, Zhuhai, Guangdong

Product Categories

| Air Separation Unit | CO2 Plant | Cryogenic Liquid Equipment | LNG Plant |

| New Products | Others |

New Products

-

ASME Standard Nitrogen Gas Generator

-

ASME Standard Used Oxygen Generator

-

ASME Standard Used Nitrogen Generator

-

ASME Standard Small Oxygen Generator

-

ASME Standard Small Nitrogen Generator

-

ASME Standard Liquid Oxygen Generator

-

ASME Standard Liquid Nitrogen Generator

-

ASME Standard Liquid Nitrogen/Oxygen Generator

-

ASME Standard Portable Nitrogen Concentrator Generator

-

ASME Standard Portable Oxygen Concentrator Generator

-

ASME Standard Nitrogen Generator Plant

-

ASME Standard Industrial Oxygen Generator

Popular Searches

- feeder machine

- automatic feeder

- fish feeder

- fashion buckle

- metal buckle

- Metal Belt Buckle

- Zinc Alloy Belt Buckle

- Plastic Buckle

- Metal Pin Buckle

- remote control robot

- robot arm

- palletizing

- Side Release Buckle

- commutator

- luggage strap belt

- purse hook

- Toilet Partition

- metal d ring

- D Ring Buckle

- Square Buckle

- Agv Robot Chassis

- Industrial Robot

- Winding Machine

- Auto Feeder

- luggage belt

- fish farm feeder

- automatic fish feeder

- Gold Buckle

- Round Ring Buckle

- Bag Buckle

Recommended Products

- Mini Pulse Laser Cleaning Machine 300W Max Laser Source New Condition for Metal Wood Stone Air Cooling Pulse Laser Cleaner

- 300W Air Cooled Portable Laser Cleaner Low Cost High Precision Easy Operation Customized Service Available From China Factory

- Suitable for original Samsung centrifugal compressor coolers, including first-stage, second-stage, and third-stage TM15000 models

- Supersonic spraying for the surface treatment of the shaft seal rotor

- Submarine Cable Bend Restrictors

- Characteristics and Applications of Cast Polyamide Wheels

- New Model Industrial Stainless Steel Ultrasonic Vibrating Screen Rotary Vibrating Screen for Food Powder Screening Processing

- Matcha powder ultrasonic vibrating screen vibrating sieve machine

- Application Scenarios for Polyurethane Wheels in Military Turnover Vehicles

- MOOG Servo Valve D661-4651

- Danfoss Orbital motor OMS160 151F0503

- Danfoss Orbital motor OMR160 151-0714

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jiang Wu

Hi there! Welcome to my shop. Let me know if you have any questions.

Jiang Wu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile