Home > Products > Silicon carbide and Tungsten carbide > Cast cyclone inlet head with integral silicon carbide, refractory silicon carbide wear part

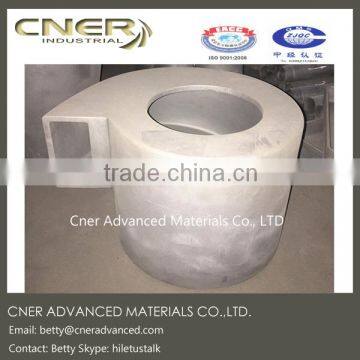

Cast cyclone inlet head with integral silicon carbide, refractory silicon carbide wear part

- 500 Piece / Pieces per Month

- Qingdao port

- T/T Credit Card

You May Like

-

High Resistance Sintered Silicon Carbide Pipes/Elbows

-

Wear Resistant Sintered Silicon Carbide Inlet Head For Minning

-

Sintered Silicon Carbide Square Tubes

-

Wear Resistant Sintered Silicon Carbide Tubes/Plates/Parts

-

Cast cyclone inlet head with integral silicon carbide, refractory silicon carbide wear part

-

Silicon carbide lined steel pipework, diameter to be ordered, Siliconised Silicon carbide lined ceramic steel pipework

Product Details

| Place of Origin | Shandong, China | Brand Name | CNER | |

| Model Number | Made-to-order | Type | Other, Cyclone part | |

| Machine Type | Other, cY | Certification | Other, ISO9001:2008 | |

| Material | Other, Silicon carbide | Processing Type | Casting | |

| Use | Coal Mining |

Product Description

1. Application: The Reaction Bonded Silicon Carbide Ceramics (RSIC/SISIC) is an good wear resistant material, especially suitable for strong abrasive, coarse particles, classification, concentration, dehydration and the other operations.

So It can effectively protect the part that need wear protection, so as to prolong the service life of the equipment with the excellent hardness and abrasive resistance.

2. Available Shape and sizes: We could produce silicon carbide ceramic tiles,tubes, and other shape as per customer's requirement. And the regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone. SISIC cyclone inlet head.

3. Packaging: Packed in pallet or wooden box.

4. Key benefits: 1. Excellent wear resistance, impact resistance and corrosion resistance; 2. Excellent flatness and excellent temperature resistance 3. Easy installation; 4. Longer service life (is about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane), which makes it to be a best choice for the Apex of cyclone and other quick-wearing spare parts.

5. Photos:

6. Certification:

7. FAQ

Q: 1. Can I have a sample order?

A:Yes,we welcome sample order to test the product quality. Kindly let us know the detailed information

Q: 2. Do you have any MOQ limit?

A:According to different type of products the MOQ limit is different.we looking forward to your inquiry.

Q:3. What is the lead time?

A: Mass production will take 15-25days, it will also depends on the order volume.

Q: 4.How about the quality of your products?

A: All of our products are conforms to the strict quality control during each processing phase.Also we have strict quality inspection procedure.

Q: 5. Can we visit your company?

A: No problem,we welcome to your arrival at any time.

Contact Us

- Zibo Cner Advanced Materials Co., Ltd.

- Contact nameDUSTIN GUO Chat Now

- Phone86-0533-6286610

- AddressNO.145 ZHENGTONG ROAD,ZIBO DEVELOPMENT DISTRICT,ZIBO CITY, Zibo, Shandong

Product Categories

| Alumina ceramic products | carbon fiber and glass fiber products | New Products | Silicon carbide and Tungsten carbide |

New Products

-

Silicon carbide lined ceramic steel pipework, Sintered silicon carbide lined steel pipe

-

High temperature resistant cyclone inlet head with integral silicon carbide, cast ceramic parts for mining machine

-

Tungsten carbide rod/alloy/tile lined for decanter, liner for centrifuge screen bowl section

-

Tungsten carbide alloy, tungsten carbide strip, wear liner of coal dewatering machine

-

High temperature resistant cyclone inlet head with integral silicon carbide, refractory silicon carbide wear part

-

Silicon carbide ceramic, wear liner for mining machine, siliconized silicon carbide plate, SiSic carbide

-

24ft Carbon Fibre Telescopic Pole with transverse clamps

-

Glass fiber materials water fed pole with clamps working for solar panel

-

25mm OD window cleaning pole for UK market

-

22mm OD Window Cleaning Poles with hybrid materials

-

22ft Water Fed Pole

-

Wear composite liner with ceramic liner and stainless steel backing plate, industrial ceramic liner

-

Alumina ceramic mat, square, hexagonal ceramic element with net backing

-

500 X 500mm Ceramic rubber wear liner with CN layer

-

Cast basalt lined steel pipe, cast basalt lined pipe, SHS ceramic steel pipe

-

High impact wear resistance rubber ceramic liner for ball mill,chute and pipe,alumina ball,brick

-

Steel and rubber backed ceramic liner

-

Ceramic lined wear resistant steel pipe, ceramic lined elbow

-

Alumina ceramic mat for easy-to-wear part, Alumina ceramic matte

-

Alumina ceramic lining tiles

-

Media heavy duty application ceramic rubber liner, with cylinder embedded

-

Ceramic rubber wear panel, with hexagonal tiles embedded

-

Ceramic rubber composite wear liner with steel backing plate

-

Ceramic lined wear resistant pipes, ceramic tiles and tube available

Popular Searches

- forging hammer

- Dth Hammer

- Drilling Hammer

- Hole Hammer

- pick

- hollow anchor bar

- wearing

- Cone Crusher Accessory

- Wearing Part

- Tungsten Carbide Button

- Chisels

- hydraulic breaker chisel

- drill rod

- Rock Breaker Chisel

- Hydraulic Hammer Breaker Chisel

- Spare Parts Chisel

- Spare Parts Rock Chisel

- Point Chisel

- Breaker Parts Chisel

- Hydraulic Breaker Rock Chisel

- Mining Machine Part

- Rock Drilling Tool

- Water Well Drilling Tool

- Rock Drill Tool

- test liner

- teeth

- chisel

- Breaker Hammer

- metallographic

- Geography

Recommended Products

- Входной фланец 5471780

- Wheel sand washing machine

- Double-axis vibration exciter dehydration screen fine sand recovery machine

- Polyurethane screen mining machinery accessories sand washing machine dehydration screen vibrating screen screen custom

- Manganese steel welding screen sand gravel screen filtration mine sand mesh welding, manganese steel mesh customization

- Pneumatic rail sawing machine Mining pneumatic cutting saw

- Guiyang 9100 Crusher Accessories Vertical Shaft Impact Crusher Impact Plate

- 561-20-71100 High Quality PARTS for KOMATSU HD465/HD785

- 721-89-12011 721-89-12010 High Quality PARTS for KOMATSU HD465/HD785

- Polyurethane screen mining machinery accessories sand washing machine dehydration screen vibrating screen screen custom

- VSIS100C crusher wear-resistant sand making machine material throwing head Short knife head

- Sand making machine accessories New type Ba*ke vertical shaft sand making machine material distribution cone flow plate

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Mining Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

DUSTIN GUO

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

DUSTIN GUO

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile