Home > Products > Blasting Room > Sand Blasting Booth With Manual Sweep Recovery System

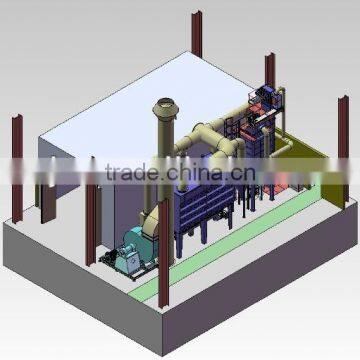

Sand Blasting Booth With Manual Sweep Recovery System

- Shanghai Port China

- T/T

You May Like

-

XDL-1206-M1 Sand Blasting Room With Manual Sweep Recovery System

-

Air Blasting Room/Booth for large steel structure

-

China Sand Blasting Room for large steel structure

-

Cheap Sand Blasting Room for large steel structure

-

XDL-1607-M2 Garnet Blasting Room for large steel structure

-

XDL-1607-M2 Shot Blasting Room for large steel structure

Product Details

| Place of Origin | Jiangsu, China | Brand Name | XDL BLASTING | |

| Model Number | XDL-1206-M1 | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

1 Engery Saving and High Productivity2 Environment Friendly

3 Customer Oriented Design

4 PLC & Touch Screen Operation

XDL-1206-M1 Sand Blasting Booth

Special For Castings, Engineering Machinery, Small & Medium Welding Structure

Shot blasting is one key technology of surface finishing in the industries of shipbuilding, steel structure,

pressure vessel, pipelines, heavy engineering machinery etc. The productivity efficiencies of shot blasting

equipments directly affects producing period; The coating quality directly affects the product service life.

Our design principle of blasting booth is: absorb advanced coating technology from abroad, combine with

the technology of hydromechanics, mechanical automation in our company, on the basis of new coating

standard, environments, clients, practical status, production scale, development space from customer, we

design and manufacture advanced technology, energy saving, stable and safe coating equipments for

the customer. This technical proposal meets the following requirements:

1) All systems of shot blasting & painting factory are designed according to new coating standards. It

must save the total invest cost as much as possible for the customer.

2) It meets the requirements of all weather operations and make sure it can do blasting & painting in any

climate conditions.

3) The design must take stability of equipments into consideration. It should meet the long time, full load

operations as long as possible and reduce as much as possible the cost of repair and maintenance.

4) Adopt new technology and improve advanced nature of equipments and not increase the investment

cost.

1.1 General Performance of Equipment

1) Blasting booth internal size: Length 12m×Width 6m×Height 5m

2) Working time: 6 hrs

3) Quantity of blasting guns: 2 pcs

4) Blasting productivity capacity: Max 2×18×6=216m2/day

5) Surface quality after blasting: Sa2.5

Roughness after blasting: 50µm~75µm

6) Abrasive kinds:

Steel Grits, steel shots and steel cut wire shots ratio is 6:3:1; Abrasive size: 0.8~1.0mm;

Hardness: HRC48°±2°.

7) Abrasive initial input quantity: 20tons/5m3

8) Abrasive recycle type: Mechanic + Manual Sweeping type

9) Air volume in blasting booth: 48000m3/hr

10) Dust emission density: ≤25mg/m3

11) Noise level: ≤85dB

12) Illuminance: Blasting Booth ≥300 Lux, Equipment Room ≥100Lux (provided by customer)

1.2 Equipment Components

1) Blasting Booth structure and foundation (Provided by customer)

2) Compressed air system

3) Swing Door ( Provided by customer)

4) Shot Blasting System

5) Shots recycle system

6) Ventilation and dust removing system

7) Illuminance system (Provided by customer)

8) Electrical control system

1.3 Project Scale for the buyer and Seller

1.3.1 The buyer:

a) Blasting booth structure, rubber sheet as protective linear of booth wall.

b) Foundation and embedded parts of equipments

c) Swing Door & Safety Door

d) Illuminance system design and outsourcing

e) Compressed air system and provide compressed air to sand blasting machine

f) Provide electrical power to main electrical control cabinet, centrifugal air blower.

g) Dispatch workers to help seller's engineers do installation and commission

1.3.2 The seller:

a) Drawing for Foundation loading capacity of equipments

b) Shot blasting system design and manufacture

c) Shots recycle system design and manufacture

d) Ventilation and dust removing system design and manufacture

e) Electrical control system design, manufacture and outsourcing

f) Manual instructions, maintenance instruction of equipments

g) Two engineers are dispatched from the seller to do installation & commission and train the operator

for operations and maintenance.

Contact Us

- Dafeng City Sanxing Machinery Manufacturing Co., Ltd.

- Contact nameCarl Chen Chat Now

- Phone0086-515-83809688

- AddressDalong Industrial Park, Xituan Town

Product Categories

| Blasting Room | Industrial Dehumidifier | Metal Abrasive | New Products |

| Other Machine Equipment | Sand/Grit Blasting Machine | Shot Blasting Machine | Vacuum Recovery Machine |

New Products

-

XDL-1607-M2 Sand Blasting chamber for large steel structure

-

XDL-1607-M2 Sand Blasting cabinet for large steel structure

-

XDL-1607-M2 Sand Blasting Booth for large steel structure

-

Garnet Blasting Room for large steel structure from China

-

China Sand Blasting Room for large steel structure from China

-

Cheap Sand Blasting Room for large steel structure from China

-

XDL-1607-M2 Air Blasting Room for large steel structure

-

XDL-1607-M2 Sand Blasting Room for large steel structure

-

XDL-SC1506-M1 Automatic Mechanical Recovery Sand / Shot Blasting Chamber

-

XDL-3309-M2 Wind Tower Blasting Booth for Sale from China

-

XDL-3309-M2 Wind Tower Sand Blasting Cabinet

-

XDL-SC1508-M1 Scraper Conveyor Type Sand Blasting Room

-

XDL-FW1805-A1 Honeycomb Floor Type Sand/Grit Blasting Room

-

XDL-1805-A1 Honeycomb Floor Type Blasting Booth for Heavy Truck Manufacturing

-

Sandblasting Room for Heavy Duty Machine

-

Blasting & Painting booths for ship body section cleaning

-

2015 Newest Air Recovery Type Honeycomb Floor Sand Blasting Booth made by XDL BLASTING

-

Blasting & Painting Rooms for Shipbuilding

-

Honeycomb Floor Sand Blasting Room from XDL BLASTING

-

Sand/Grit/Shot Blasting Booth widely used in Marine Offshore Industry

-

Air Recovery Type Blasting Booth for steel structure, pressure vessel

-

Blast Rooms for metal surface cleaning

-

LFZ9000 Tank Dehumidification / Dehumidifier for Blasting and Painting

-

LFZ12000 Ship Dehumidification /Dehumidifier for Blasting and Painting

Popular Searches

- cnc machining

- garden shear

- spare part

- belt sander

- riveting machine

- air shear

- machinery part

- precision machining

- aerospace machining

- cnc turning part

- cnc machining part

- machine part

- aluminum cnc machining part

- cnc machine part

- cnc precision machining part

- machined metal part

- cnc milling part

- cnc turned part

- repair part

- package part

- machine spare part

- replacement part

- aluminium heatsink

- plastic part

- lead alloy

- heat sink

- steel aluminum alloy

- casting part

- metal processing

- metal part

Recommended Products

- Yinfeng 0.8-10mm Automatic Spring Coil Grinding Machine

- drum wood chipper price quality Low Noise, High Power

- drum wood shredder manufacturer auto Eco-Friendly Green Energy

- wood crusher price quality Municipal Waste Management

- wood chipper manufacturer tree trunk Fast ROI for Biomass Plant Operators

- Replaceable knives wood crusher quote Fast ROI for Biomass Plant Operators

- wood shredder price tree branches Emergency Stop & Overload Protection

- wood shredder manufacturer digital Compact Design

- drum wood chipper manufacturer quality Ideal for Forestry, Farms

- Replaceable knives wood shredder diesel drive Heavy-Duty Chipping

- Replaceable knives wood chipper moveable type Chips Ready for Compost or Boilers

- drum chipper price tree trunk Built to Last

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallurgy Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Carl Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Carl Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile