Home > Products > Dry mortar production line > tower dry mortar production line,hot sale dry mortar production line

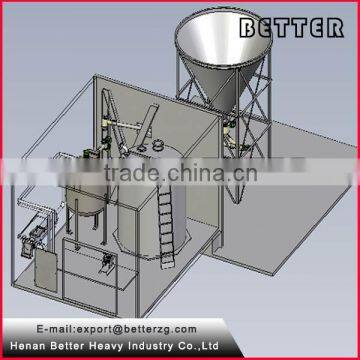

tower dry mortar production line,hot sale dry mortar production line

- 500 Set / Sets per Month

- Qingdao Tianjin or other port

- T/T Credit Card PayPal

You May Like

-

simple dry mortar production line,dry mortar production line for sale

-

simple batching plants,dry mortar production line for sale

-

Low Cost Production Line China Supplier Dry Mortar Small Manufacturing Plant

-

widely used in building construction projects dry mortar production line

-

best price dry mortar production line with high quality for sale in China

-

With ISO9001 certifications dry mortar production line with high quality for sale

Product Details

| Condition | New | Application | industry building | |

| Production Capacity | 20-25 | Place of Origin | Henan, China | |

| Brand Name | Better | Model Number | TLGF2000 | |

| Voltage | 220-380V | Power(W) | 115kw | |

| Dimension(L*W*H) | 20*15*39m | Weight | 15T | |

| Features | tower type dry mortar production line | Certification | CE&ISO9001 | |

| Warranty | 12 months | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

What is dry mortar?

Dry mortar is also called premixed mortar, which made in the factory by precise batching and uniform mixing. It can be used directly just by adding water in construction site. It has different properties though adding different additives.

Bonding mortar: Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc.

Decoration mortar: Decorative plaster, inner and outer wall putty, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self-leveling

Tower batching plants

Stationary units with high performance, designed for both, the production of ready mix, and the production of pre-cast mixtures for production of concrete elements and products.

Aggregates bin is placed above the mixing center, i.e. above the mixer and weighing systems. Bin is made by steel screwed and welded structure that is divided into 4 up to 8 chambers, according to client's requirement. Transport of aggregates into the bin proceeds by the help of bucket elevator, Z-transporter or conveyor belt. Subsequent distribution of aggregates into particular chambers is carried out by the help of rotary distributor that is located above the aggregates bin. Output of such standard equipment is from 45 m3/hour to 160 m3/hour.

Advantages of tower batching plants

1.higher output - direct dosing of aggregates into the scale, no time loss associated with weighing on regular basis (in a skip or on the belt)

2.big standby aggregates reserve - system enables storage of all needed kinds of aggregates, there are no additional external stock-yards and aggregates in bin is covered and tempered

3.easy heating - batching plant together with aggregates bin makes compact unit which is the reason for easier aggregates tempering plus warm air rise up to the bin

4.spatially modest project - there is no need of placing the aggregates bin next to the mixing center and also there is no need of any external stock yards

Dry mortar production line:

Dry mortar production line (or dry mortar machine) is a set of machinery that produces dry mortar (also known as dry premixed mortar or hydraulicity cement mortar) for construction industry and other uses.The whole process of dry mortar production line is controlled by full automatic computer program, mainly divided into following eight parts.

1.Wet Sand Drying System: reduce the water content of sand;

2.Raw Materials Storage System: store all kind of raw materials like aggregate, cement, additives and etc;

3.Lifting & Conveying System: bucket elevator, belt conveyor, screw conveyor, enmasse drag conveyor;

4.Weighing System: weigh main and auxiliary materials by computer program;

5.Mixing System: evenly mixed materials by double axle mixer, ribbon mixer and etc;

6.Packing System: finished products are packed in bags or in bulk form, then transported to other sites or stored in silos;

7.Dust Collector System: collect dust to keep a safe working and living enviroment;

8.Electric Control System: electricity control cabinet and automatic control system.

Henan Better dry mortar production line usually use steel frame structure with compact structure and high degree of automation. It can be adopted in production processes of special mortar, ordinary cement mortar, anti-crack mortar, thermal mortar, composite energy saving wall materials and etc.

1.How many kinds of mortar can this line product?

There are more than 16 kinds of mortar and this line can produce about 5 of them.If you want to produce more,we can also offer.

2, What's the difference between full automatic dry mortar plant and Semi-automatic dry mortar plant?

A: (1) Semi-automatic dry mortar plant is cheaper than full automatic dry mortar plant.

(2) Semiautomatic dry mortar plant do not need to equip material silos while full automatic type equip silos.

(3) Semi-automatic dry mortar plant is manual feeding and automatic weighing and packaging, full automatic type can realize automatic feeding and packaging.

3, How many person required to operate this dry mortar plant?

A: Usually 2-4 workers are enough to operate this dry mortar plant.

4, What equipment and service you can provide?

A: We can provide you turnkey solution of dry mortar plant from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after sales services, life time techincal support etc.

5, What is the area required for this dry mortar plant?

A: According to different capacity, the capacity required 300-1000m2.

6, What is the total power consumption (KW)of this dry mortar plant?

A: It is about 20-80kw based on the capacity of the dry mortar plant.

7, What is the capacity of your dry mortar plant?

A: We have dry mortar plant capacity from 3- 30T/H as your requirement, And also we can customize the machine for you.

8, What is the garantee period?

A: 12 months, with in this period we provide you technical services for free.

9, Can you install the dry mortar plant in my country?

A: Yes, we will send engineers to your country for guiding installation and training your workers to operate the machine.

10, If you want to know more about our dry mortar plant, please send us inquiry or contact us directly.

Contact Us

- Henan Better Heavy Industry Co., Ltd.

- Contact nameJudy Yang Chat Now

- Phone86-371-68629818

- AddressFl 18,Bldg A,Triumphal arch,Longhai and Tongbai Rd,Zhongyuan Dist, Zhengzhou, Henan

Product Categories

New Products

-

Widely used in building construction machinery dry mortar production line,high quality dry mortar production line

-

dry mortar production line price used in constructions projects

-

price of dry mortar production line with the three-cylinder dryer

-

Henan Better new product dry mortar production machinery

-

Henan Better high quality dry mortar cement mixer

-

Hot sale dry mortar mixing plant

-

Henan Better high quality dry mortar plant

-

Henan Better quick dry mortar production line

-

Henan Better quick dry mortar batch mix plant

-

sale tower type dry mortar batching plants

-

factory price dry mortar blender line

-

Henan Better mini dry mortar production line

Popular Searches

- dry mortar machines

- dry mortar mixing machine

- Dry Mortar Mix Plant

- dry mortar production line

- dry mix mortar plant

- dry mortar mixing plant

- dry mortar machine

- mortar mixer

- mortar production line

- simple mortar plant

- dry mix production line

- dry mortar equipment

- dry mortar production plant

- tile adhesive mixer

- Dry Mortar Powder Plant

- plastering mortar production line

- dry mortar plant

- dry mortar mixing machinery

- dry mix mortar mixer

- mortars production line

- tile adhesive production line

- dry mix mortar equipment

- adhesive mortar machine

- dry mortar mixer

- Mortar Mixing Line

- gypsum mixing machine

- ceramic tile production line

- tile plant

- Electric Mortar Mixer

- dry powder vertical mixer

Recommended Products

- Single-shaft Horizontal Mixer

- twin-shaft mixer

- workshop type dry mortar production line

- Dry mortar making machine dry mortar mixing production line

- electric mortar mixer dry mortar mix mortar plant mixing machine

- Warranty high efficiency facility best quality Dry Mixed Mortar whole set Equipment Machines made in china

- 5.5KW Dry Mortar Mixer Mini Plant Small Manufacturing Machines For Sale

- 7.5kw 1600L Tile Adhesive/wall Putty/waterproofing/dry Mortar Mixer Tile Mortar Mixer

- 5.5KW 2021 Horizontal Mix Sand And Cement New Screw Dry Mortar Mixer

- 7.5kw 1600L Dry Mortar Blending Machine Ceramic Floor Tile Adhesive Mixing Machine

- 5.5KW Industrial Tile Adhesive Dry Mortar Mixing Machine Dry Mortar Mixer Plant

- 15KW 3000LHorizontal Multifunctional Spiral Ribbon Dry Mortar Mixers For Sale

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Dry Mortar Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Judy Yang

Hi there! Welcome to my shop. Let me know if you have any questions.

Judy Yang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile