Home > Products > Bimetallic screw and barrel > bimetalic single screws barrel extrusion screw and barrel bimetal PTA screws and cylinder

bimetalic single screws barrel extrusion screw and barrel bimetal PTA screws and cylinder

- Ningbo/Shanghai

- T/T Credit Card

You May Like

-

bimetalic screw barrel PVC profile extrusion screw and barrel conical twin screw and cylinder PTA screws

-

Bimetallic screw barrel Injection molding screw barrel plastic injection machinery

-

High quality 38CrMoALA bimetallic extruder screw & barrel

-

SJZ-65/132 conical double screw extruder for conical twin screw barrel

-

High quality bimetallic single screw barrel for molding machine/ Chromium carbide overlay flights

-

Boiler feed screw,water cooled

Product Details

| Place of Origin | Zhejiang, China | Brand Name | Zhongyang | |

| Model Number | Dia35/76-100/200mm |

Product Description

Specifications

1.Excellent raw materials2.Good customer service

3.Short delivery time

4.Reasonable price

5.ISO9001:2008 quality control

| bimetalic single screws barrel extrusion screw and barrel bimetal PTA screws and cylinder |

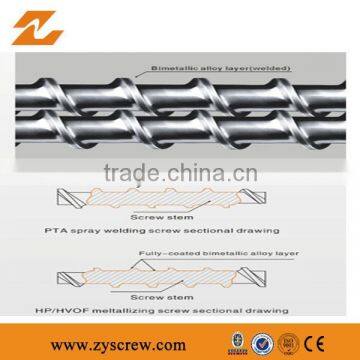

| Product Pictures of bimetalic single screw barrel |

| Product Description of bimetalic single screw barrel |

Main Base materials

| 1.38CrMoAlA (Nitriding Steel) | |

2. SKD-61 (Special Tool Steel) | ||

3. 42CrMo (Ultrahigh Strength Steel) | ||

4. DC53 (Cold Work Die Steel) | ||

5. W6Mo5Cr4V2 (High-Speed Tool Steel) | ||

6. HPT | ||

| ||

Main Alloy Materials | 1. Ni-based alloy/Deloro alloy | |

2. Tungsten carbide/Wolfram carbide | ||

3. NiCo-based alloy | ||

4. Fe-based alloy | ||

5. Co-based alloy | ||

| ||

Processing Technics | 1. Heat treatment | |

2. Quenching | ||

3. Nitriding treatment | ||

4. Bimetallic alloy welding | ||

5. Bimetallic alloy centrifugal casting | ||

6. Hard-chrome electroplating | ||

| ||

Technical parameters | Nitriding layer depth | 0.5-0.8mm |

Nitrided hardness | HRC56-58 | |

Nitrided brittleness | Less than grade 1 | |

Surface roughness | Ra 0.4 | |

Linearity of screw | 0.015mm | |

Hard-chrome plating hardness | ≥HRC57 | |

Chrome-plating layer depth | 0.03-0.09mm | |

Bimetallic layer depth | 3 mm | |

Bimetallic layer hardness | HRC58-62 | |

Above are main technical information, a suitable screw and barrel will be made according to your requirement. | ||

| Products Application of bimetalic single screw barrel |

| Packaging and Shipping |

Shipped within 30 days after receiving down payment.

Packed with Slushing oil coated and film wrapped in wooden case.

| More Products for You to Choose |

| Company Show |

Zhejiang Zhongyang Screw Manufacturing Co.,Ltd is a professional and dedicated designer,manufacturer,rebuilder and distributor of screws,barrels and assembly parts for plastic and rubber machines.With our business philosophy of quality oriented and customers foremost,Zhongyang keeps improving to offer excellent products and services to customers.Our commitment to customer satisfaction is priority number one at ZHONGYAG. |

| Why Choose us ? |

♦ Production line

♦ Exhibition Information

♦ You can depend on us for:

Working Attitude---Every employee at ZHONGYANG is a good team player.We have enthusiasm on our jobs and we do our jobs seriously and responsibly,every employee wants to do the best to contribute to our company growth at ZHONGYANG.

Quick Response---- Our sales team is well-trained with good qualifications and is passionate and ambitious,we respond quickly and efficiently.

Good Products ----- As an ISO certified enterprise since 2006,we established complete quality control system and step by step,we implement the system thoroughly from the first production process to final products now.Every production process in under strict inspection to ensure that only qualified products are sent to our customers. |

♦ Certifications

| Our Markets |

| Through years of developing, we satisfy our customer all over the world with mainly market in Europe, South America, Asia, Middle East, ect. Till now,we have served more than 100 customers from 42 different countries all over the world. And we are very confident we will have more and more customers because our teams always strive to complement and meet our customers needs in all aspects. |

| Our Services |

|

Welcome to contact us If you are looking for a reliable screw barrel supplier,you won't be wrong to choose us! |

Contact Us

- Zhejiang Zhongyang Screw Manufacturing Co., Ltd.

- Contact nameJack Zhang Chat Now

- Phone86-580-8055067

- AddressXihou industrial park,Jintang town,Dinghai district,Zhoushan,Zhejiang,China, Zhoushan, Zhejiang

Product Categories

New Products

-

bimetallic single screw barrel for molding injection machine pipe fittings

-

bimetallic single screw barrel for molding injection machine cups bottle pipe fittings

-

high quality bimetallic screw and barrel for molding injection

-

2014 high quality bimetallic screw and barrel for molding machine

-

alloy screw and barrel for plastic machine

-

Bimetallic rubber machine screw,screw barrel for rubber processing

-

Bimetallic screw barrel (welded /centrifugal casting)

-

Bimetallic injection screw and barrel

-

Bimetallic screw and barrel/injection application

-

tungsten carbide screw and barrel/bimetal screw and barrel

-

bimetal screw and barrel/injection screw and barrel

-

38 CrMoAlA single screw and barrel bimetallic

-

Bimetallic screw and barrel for extruder/ for recycled plastic

-

Manufacturing bimetallic Screw and barrel for extruder/ for aluminum plastic composite

-

Bimetallic single screw/mixing type screw for extruder

-

Tungsten carbide sjz-65/132 extruder screw and barrel

-

good wear resistance screw and barrel for recycled plastic/ bimetallic screw and cylinder

-

screw and barrel/ conical twin/ single injection molding/ single extruder

-

bimetallic feed parallel double screw / bimetallic co-rotating double screw

-

bimetallic alloy welding screw barrel / chrome-plate screw barrel

-

Bimetallic single screw and barrel for plastic injection

-

bimetallic extruder double screw

-

bimetallic screw and barrel for recycled plastic/ good corrsion and abrasion resistance

-

kennametal stellite alloy powder bimetallic screw and barrel

Popular Searches

- chair armrest

- plastic chair accessories

- plastic armrest

- Arm Pad Armrest

- Office Chair Arm Armrest

- Office Chair Armrest

- plastic chair armrest

- pu armrest

- pu foam armrest

- office chair parts armrest

- Computer Armrest

- Fixed Armrest

- Office Chair Adjustable Armrest

- pp armrest

- bed slat holder

- Adjustable Armrest

- 3d Armrest

- arm rest

- rush chair seat

- modern chair armrest

- pp chair armrest

- Chair Parts Armrest

- chair armrest arm pad covers

- ac barrel

- accessories armrest

- Chair Accessories Armrest

- Chair Armrest Accessory

- acrylic slat holders

- acrylic slat holder

- adjustable chair armrest

Recommended Products

- Underwater Pelletizing Line Spare Part PP PE Granulation Die Plate

- Heat Insulation Sealing Gasket for Granulation Die Plate of Plastic Granulator

- Automatic glue turning and mixing machine

- YC-ML003B--Open-close mixer

- Automatic glue turning and mixing machine

- YC-ML003B--Open-close mixer

- Automatic glue turning and mixing machine

- Heat Insulating Sealing Pad Used for Underwater Pelletizing Production Line for PP PE EVA Granules

- Thermal Insulation Waterproof Sealing Gasket Used for Underwater Pelletizing System for PP PE Granules

- PP PE Granules Cutting Tool Pelletizing Knife for Underwater Pelletizing Production Line

- Polyolefin Underwater Pelletizer Spares Pelletizing Knife Holder for Fixing Pelletizing Knives

- Metal-Ceramic Pelletizer Knife for Polyolefin Underwater Granulation Machine Extruder

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Mould Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jack Zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Jack Zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile