Home > Products > shoelace/handbag lace tipping machine > semi-automatic tipping machine with single simple device

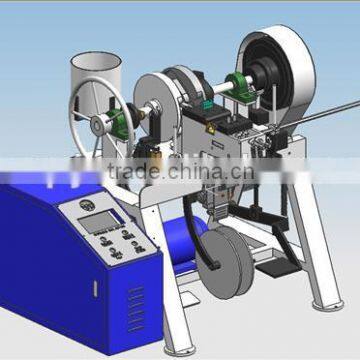

semi-automatic tipping machine with single simple device

- shanghai and qingdao

- T/T Credit Card

You May Like

-

shoelace tipping machine for marking heads

-

tipping machine for the metal shoe lace heads

-

DIY metal tips for tipping machine

-

shoelace tipping machine hand paper bag lace tipping machine rope end machine

-

tipping machine shoelace making machine CE

-

shoelace tipping machine dies/mould/knife/blade spare part

Product Details

| Place of Origin | Jiangsu, China | Brand Name | Xuzhou Qixing | |

| Model Number | tipping machine | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

1, Main structure

Main structure is composed of mechanical parts, running parts, conveyer plastic pieces parts, cutting tool parts, conveyer liquid parts, conveyer shoelaces mechanism and electrical parts.

2, Main technical data

Size: L*W*H 800*990*650mm

Weight: 160KG

Knife specification: Ø2.1, 2.3, 2.5, 2.8, 3.0, 3.2, 3.5, 3.7, 4.0, 4.2.

Plastic pieces specification: All colors, thickness from 0.2-0.25mm. Width: 25, 30, 32, 36, 40, 50mm.

Acetone consumption: 0.8kg/10000 pairs. Length freely tipped.

Heater tube: 250W. Ø12*8cm.

3, Performance

Suitable use shoelaces made of cotton, acrylic, polypropylene, polyester etc. Auto-conveyer cut and count shoelaces. Free fix numbers with sound alarm. Auto-stop when break down. Ensure safety and reliability. One person operates. Take capacity of production is 6000-6500 pairs per day.

4, Operation

Before start the machine, please lubricate each part which needs. Turn on the light on plate which indicates the heating tube is been connected with electric. It takes cutting tool 10-15 minutes to preheat 50-60℃. Put acetone into pump, release air from liquid conveyer pump. Start the motor. Put the shoelaces in the middle of the molds. Step once on the clutch and release so that one time tipping is finished.

5, Adjustment

1), Equipment has been adjusted strictly before delivery, no need to be adjusted by the user.

2), On function if the plastic pieces can not be cut, seal ends are not good. Check spray position which is on shoelaces in cutting tool or not. Adjust screw loose or tight on cutting tool. Check knife which is damaged or not. Adjust screw on cutting tool and rectify position of spray or change knife.

3), If conveyer plastic pieces runs inordinate, in case of longer or shorter, adjust conveyer plastic pieces mechanism. Check screw on pattern roller, tight roller and ratchet gear, tighten up if necessary.

4), Liquid conveyer pump is allocated type number 195 diesel. If there is no spray when the pump starts, release all air from liquid conveyer system.

6, Attention

1), Do not touch on knife with metallic matter in order to avoid damage on knife.

2), maintain voltage about 220V when production, if voltage is too high, the thermostat will be damaged.

3), Forbidden on conveyer plastic pieces twice for sealing on end, otherwise the knife will be damaged.

4), There are 4 pieces of blades as one set. Please add or change them one by one.

5), Ensure the blades are at the same level when screwing.

6), after changing the blades, check the distance between back blades and front blades.

7), If the shoelaces can’t be cut or thoroughly, please adjust the screw on the fasten cover for mold.

8), If the plastic pieces can’t be feed smoothly, please check the feeding device, pattern roller, fasten screw, and if there’s mess on the feeding device. In that case, loose the screw, clear the mess, and then fasten.

9), Normally it needs to lubricate twice during one work period.

7, How to change blades

1), release the clutch

2), cut the power

3), loose the back mold spring and take off the front and back plates.

4), firstly remove the left front blade molds. Skill is to lift up slightly of the mold’s front end.

5), after changing all blades, please follow an opposite turn to put back the molds.

7), Adopt the same method to change the right mold.

8), Operate the back mold, obey the turn from left to right.

9), Release the left back blade, change and put back the mold.

10) Release the right back blade, change and put back the mold.

11), slightly check if the distance between molds are appropriate.

12), Adjust the six-edge screw to ensure the back blades match the triangular groove.

13), Put back the two upper covers.

14), Adjust the covers and screws.

15), Adjust the distance between four molds.

16), Put back the back mold spring, adjust the tension (wide shoelaces need more tension.)

17), step on the clutch, turn the engine, try the function.

18), Attention: the plastic pieces must been feed with a right direction (naturally bend side for back mold)

19), Judge from the products of the process. Improve when needed.

Contact Us

- Xuzhou Qixing Machinery Co., Ltd.

- Contact namejinlei lv Chat Now

- Phone86-516-83162128

- AddressNO.3,xinfu road,tushanshi village,xuzhou city., Xuzhou, Jiangsu

Product Categories

New Products

-

shoelace making machine for total sets

-

QX bobbins/carriers for low speed braiding machines

-

nylon bobbins/carriers for high speed braiding machines

-

high speed spindle/carrier

-

low speed nylon/ spring/ wire spindle/carrier

-

Rolling rings traverse drive

-

QX wire/yarn releasing/pay off device

-

wire tension pay-off stand

-

high speed braiding machine spindles

-

high speed braiding machine bobbins

-

low speed braiding machine bobbins

-

low speed braiding machine spring spindle

Popular Searches

- circular loom

- weaving loom

- loom

- ribbon loom

- electricity saving device

- Quilting Embroidery Machine

- power take off

- Embroidery Quilting Machine

- weaving machine

- warping

- rope braiding

- air jet loom

- Rapier Towel Loom

- Saris

- Knitting Upper

- projectile

- loom spares

- fabric setting

- towel loom

- manual transmission assembly

- Weaving Machinery

- loom machine

- rapier

- rapier loom

- air jet

- Air Jet Weaving Machine

- Fabric Weaving Machine

- Bag Weaving Machine

- Circular Loom Machine

- high speed needle loom

Recommended Products

- Fully Automatic Shoelace Waxing Machine

- five shaft RDTW wire mesh weaving machine

- Shoelace tipping machine

- Molded pulp soft wire mesh weaving machine

- Non-film of shoelaces of header machine

- Full-automatic shoelace waxing and polishing machine

- Semi-automatic shoelace tipping machine

- PLC wire mesh weaving machine

- Reverse dutch twill weave wire msh machine Holland wire mesh weaving machine

- Lanying wire mesh machine 24mesh ultra fine wire mesh weaving loom for pressure leaf filter

- Lanying wire mesh machine 200mesh ultra fine wire mesh weaving loom for standard sieve

- Lanying filter wire mesh weaving machine fro aquaculture industry

Find Similar Products By Category

- Manufacturing & Processing Machinery > Textile Machinery & Parts > Weaving Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

jinlei lv

Hi there! Welcome to my shop. Let me know if you have any questions.

jinlei lv

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile