Home > Products > Grand ZY-80 zirconia ceramics grinding beads > 80% zirconia ceramic grinding media

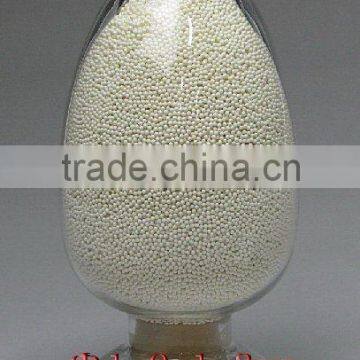

80% zirconia ceramic grinding media

- SHANGHAI

- T/T

You May Like

Product Details

| Place of Origin | Jiangsu, China | Type | Ceramic Balls | |

| Application | Industrial Ceramic | Material | Zirconia Ceramic | |

| Model Number | 1.0-1.2mm ZY-80 ZY-80 zirconia ceramic ball | Brand Name | Grand |

Product Description

Specifications

1,size:1.0-1.2mm2,material:80%zirconia

3,density:5.25g/cm3

4,type:zirconia grinding media ball

Color: Yellow

Shape: spherical

Size range(mm): Φ0.4-10mm

Φ0.4-0.6; Φ0.6-0.8; Φ0.8-1.0;Φ1.0-1.2;

Φ1.2-1.4; Φ1.4-1.6; Φ1.6-1.8;Φ1.8-2.0;

Φ2.0-2.2; Φ2.2-2.4; Φ2.4-2.8; Φ2.8-3.2;

Φ3.2-3.6; Φ3.6-4.0; Φ4.0-4.5; Φ4.5-5.0;

Φ5.0-5.5; Φ5.5-6.0; or can be customized.

Physical indicators

Density: 5.25 g/cm3

Bulk density: 3.20g/cm3

Mohs hardness: 9

Specifications: Φ1.0-1.2mm

Zirconia: 80%

Wear: <20ppm/hr (24hr)

Compressive strength: >2000kN(Φ2.0mm)

1.This product is first developed by our company engineer .At present our product is the second generation product.It has higher toughness and intensity, Lower abrasion. Not only the abrasion of the product is lower than that of zirconium silicate beads ,also lower than that of the first generation of Z80 beads. It can be widely alternative all kinds of zirconium silicate beads and TZP grinding beads In some occasions. Customers can get more efficient and more economical use cost and effect.

2. The higer proportion of the grinding beads lead to the higher crushing kinetic energy, the higher efficiency, but higher material specification quality of sand-miller also. The second generation ZY-80 product is properly reduced proportion approximately 0.1, without change of grinding kinetic energy almost . It,s microstructure has obvious improvement.Thus sander loss reduced significantly, and beads internal abrasion also decline substantial.

3. The compression strength of the beads is higher ,the broken of the beads is more difficult, and the beads have better durability. Grand ZY-80 grinding beads have advantages over other similar products in the compression strength.

4 Beads of different diameter mixed can improve crushing grinding efficiency.But it need higher quality of beads. Otherwise beads will be easily broken. A lot of suppliers emphasizes using uniform diameter beads with worrying about beads broken. Grand zirconia grinding beads can be used in different diameter without any taboo.

5. ZY-80 zirconia grinding beads have advantages over other products in the price-to-performance.

Thanks for view our products on ALIBABA.

More details please see our compay website:

We GUARANTEE a quality product at the best prices available anywhere!

Contact Us

- Jiangsu Grand Advanced Ceramics Co., Ltd.

- Contact namelivia Ou Chat Now

- Phone86-510-68980006, 87840288

- AddressEast Of No. 3 Road, Heqiao Industrial Park

Product Categories

New Products

-

80% zirconia ceramic grinding media ball

-

Ceramic beads 80% zirconia grinding beads

-

80% zirconia ceramic ball grinding machine

-

Superfine grinding 80% zirconia ceramic grinding beads

-

80% zirconia ceramic ball

-

80% zirconia ceramic grinding media

-

Pigment-80% zirconia ceramic grinding ball

-

JIANGSU GRAND zirconia ceramic ball

-

80% zro2 ceramic grinding beads

-

80% Ce-TZP zirconia ceramic grinding media

-

0.6-0.8mm 80% zirconia ceramic grinding media

-

GCZ Ce-TZP zirconia ceramic grinding media

Popular Searches

- ceramic ball

- alumina ceramic

- Alumina Ceramic Ball

- industrial ball

- ceramic filter

- ceramic substrate

- Ceramic Foam Filter

- Electrical Ceramics

- ceramic sheet

- industrial ceramic

- alumina tube

- aluminium nitride

- ceramic parts

- ceramic insulation

- zirconia ceramic

- Cordierite Ceramic

- Aluminum Nitride Ceramic

- Boron Nitride Ceramic

- Ceramic Part

- Alumina Ceramic Tube

- pottery

- resistance tube

- ceramic alumina grinding balls

- nitride

- Ceramic Rod

- ceramic tube

- advanced ceramic

- alumina pipe

- ceramic bushing

- alumina ceramic ring

Recommended Products

- RSiC grinded batts,ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setter plates

- ReSiC burner nozzles, recrystallized silicon carbide ceramic burner tubes, gas burner

- ReSiC burner nozzles, recrystallized silicon carbide ceramic burner tubes, gas burner

- RBSiC silicon carbide ceramic burner tubes, SiSiC burner nozzles, gas burner protetive tubes

- SiSiC rollers, silicon carbide ceramic tubes, RBSiC roller

- silicon nitride thermocouple protection tubes, Sialon sheath, Si3N4 stalk tubes, heating protective tubes

- RSiC batts,ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setter plates

- RSiC round plates, ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setters

- nitrided bonded silicon carbide ceramic slabs, advanced NSiC kiln shelves, NSiC setters, NSiC plain batts, SiC plates,

- SiSiC beams, reaction bonded silicon carbide kiln furniture system, RBSiC loading beams

- advanced NSiC radiant tubes, NSiC heating protective tubes, nitride bonded silicon carbide ceramic tubes,

- SiSiC radiant tubes, silicon carbide ceramic tubes, RBSiC protective tubes

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Ceramic Material > Alumina Ceramics

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

livia Ou

Hi there! Welcome to my shop. Let me know if you have any questions.

livia Ou

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile