Home > Products > MoSi2 heating element > Mosi2 electric heating tube

Mosi2 electric heating tube

- 100 Piece / Pieces per Month

- shanghai

- T/T Credit Card PayPal

You May Like

Product Details

| Place of Origin | Shanghai, China | Brand Name | Bo chuan | |

| Model Number | BC-005 | Material | Other, Silicon Carbide (SiC) |

Product Description

Specifications

Mosi2 electric heating tube1.Professional manufacturer

2,Lower price

3,Top quality& long working life

4, Up to 1400C

Mosi2 electric heating tube

We specialize in producing and selling U type molybdenum disilicide,W type molybdenum disilicide,U type right angle Molybdenum disilicide,U type bending molybdenum disilicide,I type molybdenum disilicide,L type molybdenum disilicide,The specification is Φ3,Φ4,Φ6,Φ7,Φ9,Φ10,Φ12.Our product have good reputation at home and abrode.

1) Description

1. General Description: MoSi2 heating element is a resistance generate-heating component made from MoSi2 or the basic material. It is used in high temperature under the oxidizing atmosphere, it looks like glass in its surface and form a light SiO2 glass film which can protect the element not to be oxidized. So this kind of element has unique effect for resisting oxidization in the high temperature. It is used to the highest temperature up to 1800C during oxidizing atmosphere.

2. Specific Properties: low expansion coefficient, little deformation, stable chemical property, long service life, easy installation and maintenance, etc.

3. Characteristics: MoSi2 heating element can usually make use of furnace temperature from 1300C to 1800C. It is used to the highest temperature up to 1800C during oxidizing atmosphere.

4. Application: It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc.. It is an essential ideal element when the products are sintering in the high temperature.

2) Products specification:

In addition to MoSi2 elements in standard shapes and sizes we provide customed MoSi2 elements according to customer needs,enabling an optimized element design for each particular application.

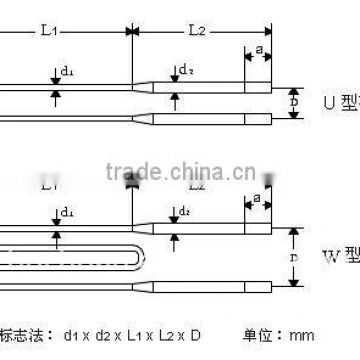

1. Types: U, W,, rod type. Or special types according to your requirement.

2. Diameter: 3/6 mm, 4/9 mm, 6/12mm, 9/18mm, 12/24mm

3. Temp: 1300-1800 Celsius degrees

Packaging Detail: | outer wooden box, cartoon box inside, polyfoam filled to ensure safety |

Delivery Detail | one or two week |

3) Technical Data

Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

4) The influence of operation temperature on the heater surface in a different atmosphere

Atmosphere | 1700 Type | 1800 Type |

Air | 1700 | 1800 |

N2 | 1600 | 1700 |

He | 1600 | 1700 |

-80°C Dry H2 | 1150 | 1150 |

-20°C Wet H2 | 1450 | 1450 |

10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

40%CO2, 20%CO | 1400 | 1450 |

Cracked and Partially Burnt Ammnia | 1400 | 1450 |

5) MoSi2 heating elements physics and chemistry characters:

1. Physics Characters

Volume Density | Bending Strength | Vickers Hardness | Porosity | Water absorption | Heating Elongation Rate |

5.5 g/cm3 | 15-25 kg/cm3 | (HV)570kg/mm2 | 7.4% | 1.2% | 4% |

2. Chemistry Character

MoSi2 heating element is used in the high temperature under oxidizing atmosphere. It will form the SiO2 film which can keep the element from being melted. During the oxidizing process, the SiO2 protecting film is formed again when the element continues to be used. The MoSi2 heating element must not be used in the temperature between 400C and 700C for a long time, otherwise the element will be cremated under the strong oxidizing function in the low temperature

Contact Us

- Shanghai Bochuan Silicon Carbon Rod Manufacturing Co., Ltd.

- Contact nameaimei zhu Chat Now

- Phone86-21-53082678

- AddressRm. 1A35, No. 666

Product Categories

New Products

-

Heat treat ceramic silicon carbide muffle section D shape furance liner

-

Al2o3 ceramic alumina muffle furnace core

-

Al2o3 Alumina Ceramic Hearth Core for High Temperature Electric Muffle Furnace

-

External Ceramic Chamber

-

Silicon Carbide Furnace Core

-

Silicon carbide cavity

-

High Alumina Hearth Plates

-

corundum mullite ceramic board

-

mullite refractory plate

-

Infrared Ceramic Plate

-

Silicon carbide grooved plate

-

High alumina furnace chamber

Popular Searches

- feeder machine

- automatic feeder

- fish feeder

- fashion buckle

- metal buckle

- Metal Belt Buckle

- Zinc Alloy Belt Buckle

- Plastic Buckle

- Metal Pin Buckle

- remote control robot

- robot arm

- palletizing

- Side Release Buckle

- commutator

- luggage strap belt

- purse hook

- Toilet Partition

- metal d ring

- D Ring Buckle

- Square Buckle

- Agv Robot Chassis

- Industrial Robot

- Winding Machine

- Auto Feeder

- luggage belt

- fish farm feeder

- automatic fish feeder

- Gold Buckle

- Round Ring Buckle

- Bag Buckle

Recommended Products

- High Power 2000w Handheld Laser Cleaning Machine Metal Oil Paint Rust Removal Stainless Stone Laser Cleaner Car Repair

- 300w Handheld Pulse Laser Cleaning Machine for Grease Cleaning and Weld Processing

- Portable Hand Laser Cleaning Pulse Laser Cleaning Machine Metal Rust Oil Stain

- Jinan Thermal Spraying Plasma Processing of Silicon Carbide Coating

- 50w 100w 200w Portable Handheld Laser Cleaning Machine for Rust Removal for Metal Surface Small and Light

- New Pulse Laser Cleaning Machines 200w Industrial Laser Cleaning Machine Portable Hand-held Laser Rust Removal

- Selling Better Handheld Pulse Laser Cleaning Machine Laser for Cleaning Rust and Paint for Metal Surface

- 50w 100w Backpack Laser Cleaner Machine Cleans Laser Cleaning Machine for Rust Removal Laser Cleaning Rust Machine

- Portable Mobile Backpack 100w Pulse Fiber Laser Cleaner Rust Removal Cleaning Machine with Lithium Battery

- Small 2000W Laser Rust Removal Machine for Rail Steel Plate Cleaning

- 1500W Laser Rust Remover Machine 10m Optical Fiber Hull Rust and Paint Removal

- Mobile Laser Rust Removal Machine 200w Universal Wheels for Easy Move Cleaning Welds

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

aimei zhu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

aimei zhu

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile