Home > Products > Polyurethane Board Production Line > Guangxing Machinery Automatic Continuous Polyisocyanurate (PIR) Insulation boards Production Line

Guangxing Machinery Automatic Continuous Polyisocyanurate (PIR) Insulation boards Production Line

- Tianjin Xingang Dalian Qingdao

- T/T

You May Like

-

Automatic Continuous PUR Panel Production Line/Polyurethane Panel Laminating Machine

-

BV Certification PU Sandwich Panel Roll Forming Machine

-

TUV Production Line for Polyurethane Decorative Wall Panel

-

BV Certification Production Line for Polyurethane Decorative Wall Panel

-

Production Line for Polyurethane Decorative Wall Panel

-

BV Certification Machine for Cold Room Polyurethane Insulation Panel

Product Details

| Place of Origin | Hebei, China | Brand Name | Guangxing Machinery | |

| Model Number | GX100, GX200 | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

ISO9001&CE Certification27 Years' Experience

1 Year Warranty,Lifetime Service

Polyisocyanurate Board Production Line

Guangxing Machinery is China's largest manufacturer of Polyurethane /PUR/PIR Machinery !

With powerful R&D team,we have been in Polyurethane/PUR/PIR Machinery since 1987.

Mob:0086-13633315608 skyp: hbgxmachinery07 , wechat: s2729355624 . More Details , CONTACT NOW !

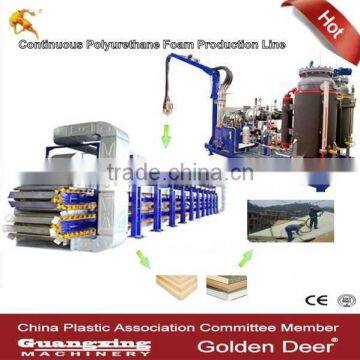

Guangxing Machinery Automatic Continuous Polyisocyanurate (PIR) Insulation boards Production Line

The whole line mainly include:

- Soft Surface Decoiler System,

- High Pressure PIR Foaming Machine,

- Double Belt Conveyor,

- Automatic Cutting System,

Our machine can meet your demands with various soft surface: non-woven fabrics,aluminum foil, glass fiber mat, kraft paper,etc.

Advantages:

1.The equipment is accurate and durable.

2.The tape mechanism has a tension control device, enabling the overlay material evenly into the mould, to make sure the piece has a smooth surface.

3.The side block and adhesive tape recirculation device can guarantee the sealing of the piece and its demoulding.

4.The double-crawler laminating system is of pressure proof, and can achieve a continuously automatic production and limit the foaming material within the mould, ensuring a stable feature in product size.

5.The following conveying and cutting systems can work simultaneously to produce plates of any length.

Technical Parameters:

ITEM | UNIT | PARAMETER |

Effective length of laminating machine | mm | 18000--36000 |

Effective width of laminating machine | mm | 1200 |

Effective height of laminating machine | mm | 20--100 |

Laminating machine temperature control range | °C | ≤80 |

Foaming casting machine flow | Kg/min | 6--25 |

Anti-pressure capability of laminating machine (25°C) | Mpa | 3 |

Anti-pressure capability of laminating machine (70°C) | Mpa | 2.8 |

Suitable production thickness | mm | 20--100 |

Capacity | m³/24h | 200 |

Dimension L*W*H | Mm | (40000--60000)*3000*4000 |

Installed power | KVA | 60 |

Total weight | Tons | 40--72 |

Working flow:

Chain plate processing:

The heating treatment bring the chain plate a high strength, non-deformation and high resistance to the expansive force from high-density products.

Laser cutting and hole drilling processing provides the precise standard of the spare parts.

Frame Processing:

CNC grinder guarantees the smooth surface of the frame.

Assembling:

Product samples of the machine:

Final products samples and applications:

Appearance of the machine:

Seaworthy packaging

Turn-key projects service

27 years' designing, manufacturing and supplying custom engineered experience

Professional R&D Team

114th China Import And Export Fair(Canton Fair) ly21

115th China Import And Export Fair(Canton Fair) 7.1 C39

Member of China Foam Association

Certification

Plant overview:

1 This line is a continuous production line.

2 It used to make rigid polyisocyanurate (short as PIR) for building insulation.

3 1 Year warranty

4 Outstanding technical&after-sale services, lifetime technical support

Welcome to contact us for business cooperation !

hbgxmachinery07 AT gmail DOT com , Mob: 13633315608

Contact Us

- Hebei Guangxing Machinery Technology Co., Ltd.

- Contact nameGavin Zhao Chat Now

- Phone086-0311-87899866

- AddressNanlv Village Industrial Area

Product Categories

New Products

-

Automatic Continuous Polyurethane Insulation Slab Making Machine / PUR Foam Board Production Line

-

Automatic Continuous Polyurethane PUR Insulation Board Production Line

-

BV Certification Phenolic Machine for Phenolic Foam Panel

-

High Pressure Polyurethane Spray Foam Machine For Sale

-

Continuous Rigid Polyurethane Machine

-

Rigid Polyurethane Block Machine

-

Pheumatic High Pressure PU Machine

-

High Pressure Polyurethane Pouring Machine

-

Polyol Isocyanate High Pressure Machine

-

High Pressure Polyurethane Forming Machine

-

High Pressure Polyurethane Foam Injecting Machine

-

High Pressure Polyurethane Foam Machine

-

High Pressure Polyol Isocyanate Foam Machine

-

German Tech High Pressure Polyurethane Foam Panel Machine

-

Rigid Polyurethane Panels Production Machine

-

BV Certification Machine for Polyurethane Foam Pipe Insulation

-

High Pressure Polyurethane Machinery

-

Polyurethane Equipment

-

Russia Market Machine for Polyurethane Foam Pipe Insulation

-

Widely Used Polyurethane Insulation Foam Machine

-

Top Performance Continuous Automatic Polyurethane Foam Machine for Insulation Wall

-

Excellent Performance Low Pressure Polyurethane Foam Machine

-

Widely Used High Precision Continuous Polyurethane Foam Machine

-

Top Quality High Pressure 2 components Polyurethane PU Foaming Machine

Popular Searches

- wall board machine

- pile concrete

- concrete form machine

- button heading machine

- eps panel line

- laminate plant

- leca production line

- product posting

- products posting

- precast prestress concrete

- purling machine

- precast hollow core slab

- roof pannel

- sale installer

- sales installer

- drawer slides roll forming machine

- automatic rock

- brand installer

- board machin

- board equipement

- corrugate asbesto

- light expanded clay aggregate

- discontinuous pu line

- eps coating

- factory installer

- line panel

- brown fullness machine

- grage

- line shelf

- premium lime

Recommended Products

- Mineral Stone Basalt Panel Making Machine Stone wool Production Line Natural Gas Basalt Rock Wool Making Machine

- gypsum board laminating machine gypsum tiles making machine

- rock wool making machine rock wool machine stone wool making machine

- stone wool production line mineral wool production line rock wool production line

- pur/pvc laminated hot glue press machine pur foil laminating machine pur 1300 lamination machine

- small floor mgo board production line board making manufacturing machine

- small scale gypsum board lamination machine 600*600 gypsum ceiling tiles making machine

- automatic rock wool production line rock basalt mineral wool production line rock wool line production

- small capacity 60x60 pvc laminated gypsum ceiling tiles board laminating making machine production line

- full automatic gypsum board perforating machine gypsum board punching machine

- Pneumatic spray machine Steel structure special multi-functional high pressure airless spray machine environmental protection and paint saving

- sale for Temperature plate slotting machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Board Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Gavin Zhao

Hi there! Welcome to my shop. Let me know if you have any questions.

Gavin Zhao

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile