Home > Products > Homogenizer /High Shear Mixer/In-line mixer > JKE High Quality High Shear Dispersing Emulsifier for Daily Flavor and Fragrance

JKE High Quality High Shear Dispersing Emulsifier for Daily Flavor and Fragrance

- shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Condition | New | Mixer Type | Homogenizer | |

| Product Type | Other, Chemical | Application | Liquid with Suspended Solids | |

| Additional Capabilities | Milling | Place of Origin | Jiangsu, China | |

| Brand Name | JKE | Model Number | PHM | |

| Max. Loading Capacity | 500L | Voltage | 110V~480V | |

| Power(W) | 1.5kw~132kw | Dimension(L*W*H) | 575mm*370mm*320mm | |

| Certification | ISO9001 CE | Warranty | 15 Months | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

JKE High Quality High Shear Dispersing Emulsifier for Daily Flavor and Fragrance

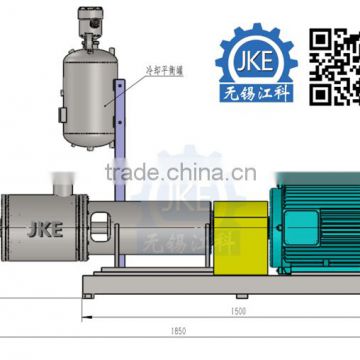

PHM in-line mixer is suitable to in-line production or recycling processing of highly flowability liquid materials, fulfilling the shearing, dispersion, homogenizing and mixing, emulsion process requirements of liquid-liquid phase and liquid-solid phase materials.

After materials are imported from the device into the working chamber, they will pass through multiple shear planes and shear layers of mutual occlusive multi-layer stator and rotor, causing hundreds of times combination action of strong shearing, impacting, grinding and cavity, which can make remarkable effects of shearing homogeneous emulsion. The technical parameters can be modified and optimized according to requirements of specific materials and different operation mode. Also the machine has self-absorption capacity and a certain export transmission capacity.

The type adopting sanitary stainless steel material, manufactured precisely, can maximize the stability of equipments on the basis of mixed emulsion effects.

1. New structure split multi-layer and multi-directional super shearing technology, new stator and rotor structures, optimal effect of shearing process.

2. New flow field the eccentric rotor structure forming strong delivery flow field, stator using combination of positive & negative revolve and ultra-fine slot, Fluid turbulence to make the mixing process more thoroughly.

3. More Reliable integrated mechanical seal, solving the leakage of materials and the cooling medium pollution under high-speed operation by the greatest extent, installing and replacing conveniently.

4. More Stable using optimal design, effective integration of advanced technology and innovative thinking, reflected in the design of specific structures, providing a guarantee for the stable operation of the equipment.

1.Soluble (or miscible materials) solid and liquid in accelerated dissolution.

2.Immiscible solid-liquid phase suspensions in superfine mixing dispersion.

3.Immiscible liquid-liquid phase solution in inclusive micro-emulsion.

4.High-viscosity material powder-liquid in overall mixing and superfine dispersion.

5.Particles and fat balls in solution in superfine shattering and homogenizing.

6.Animal and plant tissues in superfine shattering and slurrying processing.

7.Nanomaterial aggregates in strong deploymerization and superfine dispersion.

8.Food fiber materials in wet ultrafine cutting and homogenizing.

No | Model | Power | (rpm)Rotor speed | (M3/h) Corresponding flow | (mm) Inlet diameter | (mm)Outlet diameter |

1 | PHM-60 | 1.1kw | 3000 | 0-1.5 | 25 | 20 |

2 | PHM -100 | 1.5kw | 3000 | 0-3 | 40 | 32 |

3 | PHM -125 | 4kw | 3000 | 0-5 | 50 | 40 |

4 | PHM -150 | 7.5kw | 3000 | 0-10 | 50 | 40 |

5 | PHM -180 | 15kw | 3000 | 0-18 | 65 | 50 |

6 | PHM -200 | 22kw | 3000 | 0-25 | 65 | 50 |

7 | PHM -220 | 37kw | 3000 | 0-35 | 80 | 65 |

Note:

1.The flow range in the table means the data when the media is water.

2.Adjusting speed adopts variable speed or variable speed inverter. It can work together with cooling or heating device.

3.Interface way can choose (hoop, thread, and flange).

4.Material of the pump body can choose SS 304, SS 316, and SS316L.

5.Sealing material: Standard rubber ring is silicone rubber, according to the media requests; you can choose fluorine rubber, EPDM, PTFE.

1. The above machine which we supply it to you, we can give you 12 month after sales warranty.

2. Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

3. Any damage except the wrong operation during warranty period is repaired freely. We guarantee will send it to customer by DHL, Fedex, UPS etc. If we have parts in our warehouse,we will send within 24 hours, if we don't have it in our warehouse, we will manufacture it with our fast time.

3. Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

4. We can also send our engineer to you factory to install the equipment and train your staff if you need, but the Buyer should pay the round air ticket cost and arrange the hotel accommodation as well as the means for Seller’s engineer. Our engineers will train your staff to operate the machine during the period of installation and commissioning, and they will not leave from you side until your staff can operate it properly and normally. The customer need pay 80 USD/day for our engineer.

5. Certificate services: we can provide related certificates to customers freely according to the request of customers. Like Form A , Form E, Certificate of origin, CE, Free fumigation certificate etc.

6. Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment. Also, we will send the detail information for the machine, it include manual, video, photos,Circuit diagram etc.

7. Shipment document service: We guarantee that after receiving all of shipment files, we will send it to customer within 24 hours by DHL, Fedex, UPS etc. For Bill of loading, customer can choose original or Telex release.

8.The customer can contact with seller by phone, e-mail, Skype etc, we promise will keep our mobile is open full days (24 hours).

Contact Us

- Wuxi JKE Automation Technology Co., Ltd.

- Contact nameBilly Yang Chat Now

- Phone86-510-82121280

- Address73th,Qianwei Road, Wuxi, Jiangsu

Product Categories

New Products

-

PHM Pipelined high viscosity material superfine dispersing mixer

-

PHM Hot Sale Open Tank Inline Homogenizer Disperser

-

pre-gelatinized "cold water" starches Into Liquid Disperser (DISPERSHEAR)

-

Inline Shear Pumps

-

PHM High Shear Mixer Inline Mixer

-

Pipelined High Shear Dispersing Emulsifier

-

HM Paint Dissolver Paint Disperser Paint Mixer

-

HM-100L Pilot high shear homogenizer

-

In-Line Disho Dispersing Mixer and Homogenizer

-

Emulsification Machine Liquid Homogenizer Homogenizer Agitator

-

PHM in-line high shear dispersing emulsifying mixer

-

JKE Intermittent High Shear Dispersing Emulsifier Blender

-

Soy Proteins high shear mixer

-

JKE HM-100L High Shear Batch Operated Pilot Plant Homogenizer Mixer

-

Food Homogenizer Mixer High Shear Emulsifying Pump In-Line Homogenizer

-

PHM Sanitary Stainless Steel Emulsification Pump

-

PHM In-Line Emulsion Pump Inline Ultra Sanitary Mixers

-

JKE High-Authority Sunction-Power Mixing Dispersing Emulsifier

Popular Searches

- mixing tank

- mixing machine

- Lab Mixer

- Liquid Agitator Mixer

- Powder Liquid Mixer

- Blender Mixer

- Drum Mixer

- food mixer

- scrape equipment

- dough mixer

- planetary mixer

- spiral mixer

- Spiral Dough Mixer

- stainless steel tank

- mixing equipment

- powder mixer

- homogenizer

- high speed mixer

- Ribbon Blender

- Powder Blender

- Bin Blender

- button making machine

- vacuum machine

- button press machine

- Soap Making Machine

- Chemical Equipment

- Chemical Agitator

- bubble gum base

- pharmaceutical machine

- Chemical Mixing Equipment

Recommended Products

- Automotive Cabling Harnessing and Connections glue dispensing machine with 2 part epoxy potting compound

- 2k glue potting machine polyurethane dispensing and mixing machine for Fuel Level Sensors

- Power Steering Console two part epoxy pu silicone dispensing and filling glue machine

- Dashboard control borad PCB 2 component epoxy silicone pu dispensing and dosing glue machine CNC automatic

- Electric Vehicle Batteries AB 2k part epoxy resin and hardener metering and mixing pouring filling equipment machine

- Marine Electronics 2k resin mateirals glue potting machine epoxy dispenser PU dosing and mixing machine

- LED Beacons / Navigation / Safety lights potting and encapsulation machine with two parts epoxy potting compound

- Radar / Radio Antenna / GPS sensor PU and epoxy dispensing pouring filling equipment

- Depth Gauges glue potting machine epoxy potting machine 2k pu dispensing machine

- Climate control shipping container controls PCBA ab glue dispensing machine ab epoxy and hardener mixing and dosing machine

- Unmanned Underwater Vehicles (UUV) ab two component urethanes dispensing and potting machine

- 2k Mixing and dosing Unit machine for Electric Motors for Anchor Winches / Mast Controls potting and encapsulation

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mixing Equipment > Mixing Tank

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Billy Yang

Hi there! Welcome to my shop. Let me know if you have any questions.

Billy Yang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile