Home > Products > Block Making Machine > QT8-15 Earth paving block making machine with BV certification

QT8-15 Earth paving block making machine with BV certification

- xiamen

You May Like

Product Details

| Condition | New | Type | Hollow Block Making Machine | |

| Brick Raw Material | Cement | Processing | Brick Production Line | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | 100SETS/MONTH | Place of Origin | Fujian, China | |

| Brand Name | XIEXING | Model Number | QT8-15 | |

| Voltage | 380V | Power | 34.6KW, 34.6KW | |

| Dimension(L*W*H) | 3300*2200*2990MM | Certification | CE/BV/CIQ | |

| Warranty | 1year | After-sales Service Provided | Engineers available to service machinery overseas |

seaworth

Product Description

QT8-15 Earth paving block making machine with BV certification

First,Earth paving block machine description

1, Due to reasonable structure,it is very convenient for exchanging the cutter,operating and maintaining.The equipment is tight-fixed with stable and reliable quality.Perfect designing,such as,adopting the auto pallets feeding system,material conveying and laying out system,compulsive material disposing system and pressing and molding synchronously,has made the production recycling automatically with high production output and stable quality.Auto stacking system will enable the equipment to play higher effciency.

2, Machine,electricity,hydraulic are all combined together and controlled by PLC with the optional locking password to protect the running with safety.Main control table is with computerized operation screener (Chinese/English menu,LCD touching screen),which can materialize the parameter setting,single collecting along with the machine and breakdown analyzing,thus the machine can keep in the best working status.By long-distance monitoring,breakdown seeking and system updating.

3, Being vibrated by the hydraulic-pressure motor,this machine lays the material fast by two manipulators controlled by oil cylinder,which has raised up the vibration and the vibration efficiency.The material is laid evenly while being molded in a short time.The compressing and vibration are organic combined to guarantee the density of the products.

Second, Technical Datas for QT8-15 earth paving block machine product line

| 1. Detailed specification: | |||

| Dimension of host machine | 3500×2220×2850mm | control style | PLC |

| forming style | Hydraulic | Vibration force | 100KN |

| vibrator style | table and mould vibrate | material feeding style | 360 degree revole |

| forming hight | 40-250mm | moulding period | 15-20S |

| moulding aera | 1025×810mm | size of pallet | 1350×900×30mm |

| weight of host machine | 14ton | Mixer style | JS750 |

| General water Consumption | 12T/day | Voltage | 220/240/380/440V |

| Simple block machine line area needed | |||

| Workshop | 200m2 | ||

| Office | 100m2 | ||

| Total area | About 2000m2 | ||

| Worker arrangement | |||

| operate | 1 | Material loader | 1 |

| Drive forklift | 1 | Feeding pallets | 1 |

| Maintain | 1 | Total | 5 |

| Production capacity | |||

| Size(L x W x H) | Pcs /Mould | Pcs / Hr | |

| 400X100X200 | 20 | 3000-3600 | |

| 400X150X200 | 14 | 2100-2520 | |

| 400X200X200 | 10 | 1500-1800 | |

| 400X250X200 | 8 | 1200 | |

Third, QT8-15 Earth paving block machine quality details

|  |

| Schneider electron used in PLC control system | Product line PLC control system face-plate |

|  |

| The hydraulic station details | |

|  |

| 360degree rotating and compulsory feeding system(make the block material well-distributed) | |

|  |

| Engineer install and test the product line before delivery | |

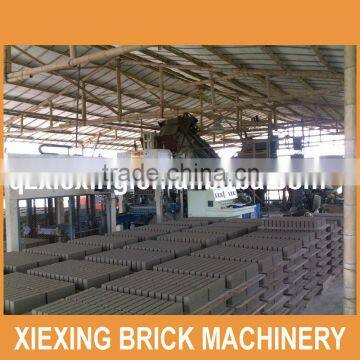

Fourth ,QT8-15 Earth block machine product line working pics

Fifth, The brick samples made by QT8-15 earth paving block machine

Sixth, The raw material batching ratio for QT8-15 earth paving block machine

| Plans 1 | coal powder 30%, slag 30%, saltpeter powder 30%, cement 8~10% , arenite concentrates powder 0.2% | |||

| Plans 2 | Stone powder 60%, saltpeter powder 3%, cement 8-10%, calces 3%, ash 0.2% | |||

| Plans 3 | Sand 60%, Stone powder 30%, cement 10~15%, mortar adhesive 0.5%. | |||

| Plans 4 | Shale 90%, cement 8~10%, arenite powder 0.2%, potassium chloride 0.2%. | |||

| Plans 5 | Iron ore powder 60%, Stone powder 30%, cement 10-15%, arenite concentrates powder 0.2%, potassium chloride 0.2%, early strength agent 0.2% | |||

| Plans 5 | Fly ash 60%, slag 30%, cement 8~10%, arenite concentrates powder 0.2%, | |||

Seventh, Earth paving block machine certifications

Eighth,Earth paving Block machine customers cases

Ninth, FAQ for earth paving block machine

Questions | Answers |

How to contract with you | Skype:catherine6518 Telphone:+86-13062424086 |

What is the productivity of the brick machine? | Different brick machine with different productivity of different brick size.please contact the customer services to give you the detail productivity |

What is the electric voltage and rate? | Our local electric voltage is 380v, 3phase, 50hertz, the electricl voltage can be revised according to local situation |

Is PLC fully automatic or semi automatic? | PLC can be fully automatic and semi automatic, according to our experience, we recommend you fully automatic PLC to you. It is easier to operate fully automatic PLC, thus saving labour cost. |

Warranty period your company | 12 month after delivery. |

Do you have enterprise website? | |

How many molds come with one brick machine? | One brick machine come with one mold free, the extra mold need to buy extra. |

Hong long can the molds be used? | 150,000times, after repair, can you use another 150,000times. |

The life of the machine? | One brick machine can be used 6-10 years in common using station |

The mode of transportation. | by sea, by land or by rail according to situation. |

The production time of the brick machine? | The general production time about 20days , the specific time depend on the specific situations. |

Company Profile

Quanzhou Xiexing Machinery Making Industry Co., Ltd. comes from China, is a specialized company, which has been in the cement products machinery industry for over ten years. Our main products are brick machines, block machines, concrete block machines, cement block machines, hollow block machines, non-burn block machines, color block machines, hydraulic block machines, pressing machines, block moulds and other more. Xiexing judges each procedure of the work by taking the market as guideline and the actual requirements as standard goal. Now, our company has already set up a more complete system in innovation, manufacturing, quality controlling and after-sales service. Scientific design, advanced product technology, complete production equipment, experienced working craftwork, strict inspection as well as the specialized group have resulted in excellent and superior products in Xiexing. Our good service support has eliminated the worry of customers. Xiexing seeks for superiority and perfection. For this goal, everybody in Xiexing is working hard!! Our hearted spirit is "Sincere collaboration, going prosperous with you"!!

Contact Us

- Quanzhou Xiexing Machinery Making Industry Co., Ltd.

- Contact nameGary Xie Chat Now

- Phone0086-595-22472787

- AddressXiexing Building, Huangshi Industry Area, Fuqiao , Quanzhou, Fujian

Product Categories

New Products

-

XQY6-24 Automatic hydraulic block making machine with certificed quality

-

QT6-15 Hot sell cement block forming machine with top quality

-

QT6-15 Hot sell concrete block forming machine with top quality

-

QT10-15 fully aotomatic construction material machine

-

Top quality Hot sale XQY3-10 small industry block machines in india Supplier's Choice

-

2015 XQY6-24 Automatic curb block machine road block machine interlocking block machine

-

2015hottest selling XQY8-40 Automatic road brick machine curbstone brick machine interlocking brick machine

-

2015 XQY10-50 Automatiac clay brick making machine cement brick forming machine concrete brick forming machine

-

2015 Automatic XQY12-60 paver block making machine interlocking machine road block machine curbstone block making machine

-

Top quality QT4-15 full set automatic construction material machine Quality Choice

-

Top quality QT4-15 full set automatic cement machine with best price

-

QT10-15 fully aotomatic paving brick forming machine

-

QT10-15 high quality hollow block forming machine

-

QT10-15 high quality hollow brick forming machine

-

QT6-15 Hot sell concrete brick forming machine with top quality

-

QT6-15 Hot sell block forming machine-construction machinery

-

QT10-15 high quality pavement brick forming machine

-

Top quality QT4-15 pavement brick machine with best price

-

QT6-15 Hot sell paver brick machine with top quality

-

Top quality QT4-15 hydraulic brick making machine with best price

-

2014 hot sell QT4-15 hydraulic interlocking brick making machinery

-

QT4-15 Hydraform pavement brick making machine

-

QT10-15 high quality pavement brick machine with special price

-

Hottest selling XQY4-26 interlocking block making machine

Popular Searches

- Sand Making Machine

- Sand Making Production Line

- building model making

- Asphalt Mixers

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- Asphalt Concrete Mixer

- Mobile Asphalt Mixer

- Asphalt Bitumen Mixer

- Asphalt Mixer Plant

- vehicle equipment

- paver

- Making Machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- Asphalt Drum Plant Bitumen

- double drum

- Brick Making Machinery

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Gary Xie

Hi there! Welcome to my shop. Let me know if you have any questions.

Gary Xie

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile