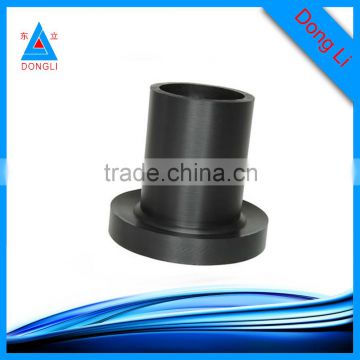

Home > Products > PE Fittings > Supply HDPE Flange Fitting Plastic Stub End 1.6MPa Price

Supply HDPE Flange Fitting Plastic Stub End 1.6MPa Price

- Qingdao Shanghai Ningbo Shenzhen Guangzhou

- T/T

You May Like

-

Black Color HDPE Pipe Fitting Flange Stub End PN16

-

Black PE100 Fitting HDPE Flexible Pipe And Fitting PN1.6

-

HDPE Injection Molding Fitting PE100 Pipe Fitting 1.6MPa

-

Plastic PE Fitting Water Supply Pipe Fitting HDPE Fitting Reducer Coupling

-

Pressured HDPE Water Supply Pipe Fittings PE100 Pipe Fitting

-

Pressured HDPE Fitting Connection Fitting Threaded Fitting PN16

Product Details

| Material | Plastic | Technics | Other, injection molding | |

| Type | Tee | Place of Origin | Shandong, China | |

| Model Number | dongli | Brand Name | dongli | |

| Connection | Welding | Shape | Equal | |

| Head Code | Other, round |

Product Description

HDPE Fabricated Fittings HDPE Plastic Fittings Tee

HDPE Fabricated Fittings advantages:

1.Certifications:BV,ISO9001,ISO14001,ETC

2.Material:basell raw material (basell CRP100) without any recycled material in the products

3.Stable domestic market with one of the top 10 brand business

4.We have a mount of 50,000,000RMB products in our stock

5.Imported battenfeld machines,and the proportion of screws in the machines is 33:1,as we all know,the longer screws,the better it produces with mixed raw material

6.most of our products are for government in local and worldwide.

7.OEM and ODM are accepted

HDPE Fabricated Fittings Details:

PE pipe and fittings are free from corrosion in all ground conditions and its flexibility allows it to withstand ground movements. No protective layers or finishes are required.

PE systems can be fusion welded so there is no risk of leaking from joint distortion. PE pipe is available in coils in long lengths. PE pipe is a common choice for trenchless technology.

PE fittings complete the PE pipe package using electrofusion and butt welding technology for jointing.

- Suitable for both gas and water polyethylene applications

- Available in SRD11, 13.5, 17, 21 and 26, PE80 or PE100

- Elbow, Equal Tee, Reducer, Reducing Tee, Stub End & End Cap in sizes of 20mm up to 800mm are all available

- State of the art injection molded technology, no fabrication needed as all fittings are produce in one piece

- Uncommon fittings such as Reducing Elbow, Reducing Tee and Reducer can be assembled upon special request

- Meticulous turning of clamped part ensure fitting’s roundness and precise dimension

- Thicker Wall thickness in none cocket zone ensure fitting reliability and performance

- Compliance with ISO Standard & BS EN 12201-3:2003

- Light weight and flexible

- Safe, leak proof and easy jointing by using electro fusion fitting or butt fusion.

Applications:

1. City and town water supply system

2. Sea bed water supply system

3. Food and chemical industry

4. Replacement of cement pipes and steel pipes

5. Argillaceous silt, mud transportation

6. Garden green pipe networks

Company introduction

THREE CONNECTION METHODS:

1.Socket Fusion Joint

This technique consists of simultaneously heating both the external surface of the pipe and the internal surface of the socket fitting until the material reaches fusion temperature; inspecting the melt pattern; inserting the pipe end into the socket; and holding it in place until the joint cools.Mechanical equipment is available and should be used for sizes larger than 2 inch diameter to attain the increased force required and to assist in alignment.

Follow these general steps when performing socket fusion:

1.Select the equipment

2.Square and prepare the pipe ends

3.Heat the parts

4.Join the parts

5.Allow to cool

2.Butt Fusion Joint

The most widely used method for joining individual lengths of large diameter polyethylene pipe is by heat fusion of the pipe butt ends.This technique, which precludes the need for specially modified pipe ends or couplings, produces a permanent, economical and flow-efficient connection. Field-site butt fusions may be made readily by trained operators using specially developed butt fusion machines that secure and precisely align the pipe ends for the fusion process.

The six steps involved in making a butt fusion joint are:

1.Securely fasten the components to be joined

2.Face the pipe ends

3.Align the pipe profile

4.Melt the pipe interfaces

5.Join the two profiles together

6.Hold under pressure

3.Electro Fusion Joint

This technique of heat fusion joining is somewhat different from the conventional fusion joining.The main difference between conventional heat fusion and electro fusion is the method by which the heat is applied. In conventional heat fusion joining, a heating tool is used to heat the pipe and fitting surfaces.The electro fusion joint is heated internally,either by a wire coil at the interface of the joint or, as in one design, by a conductive polymer.Heat is created as an electric current is applied to the conductive material in the fitting.

General steps to be followed when performing electro fusion joining are:

1.Prepare the pipe

2.Clamp the fitting and pipe(s)

3.Apply the electric current

4.Cool and remove the clamps

Contact Us

- Linyi Dongli Plastic Building Materials Co., Ltd.

- Contact nameantoney zhang Chat Now

- Phone86-539-7709369

- AddressFenghuangling ,Hedong district,Linyi,Shandong,China, Linyi, Shandong

Product Categories

| New Products | PE Fittings | PE Pipe | PE-RT Pipe &Fittings |

| PP compression fitting | PPR Pipe and Fittings | PVC Fittings | PVC Pipe |

New Products

-

Fabricated DN500 DN800 PE Welded Fitting Plastic HDPE Fitting Price

-

Plastic HDPE Carbon Pipe

-

China Hdpe Black Plastic Black Poly Pipe Fittings

-

Cap Plastic

-

Butt Weld Fittings

-

HDPE Female Union And Cap

-

HDPE Polyethylene Cross

-

HDPE Pelyethylene Pipe Equal Cross

-

HDPE Welded Cross

-

Pelyethylene Pipe Fittings Equal Fittings

-

Pipeline HDPE Insulating Support

-

Newest Tight HDPE Pipe Fittings Cross

Popular Searches

- pipe fitting

- compressed air pipe

- socket fusion

- socket fusion welding

- copper fitting

- red copper pipe

- brass fitting

- fire hose coupling

- sanitary fitting

- plumbing

- expansion joint flange epdm

- ferrule

- pex al pex pipe

- expansion joint

- fire coupling

- gas fireplace part

- stove accessory

- hdpe fitting

- hourglass aluminum ferrule

- copper pipe fitting

- cast pipe

- cast iron tube

- astm a888

- ductile iron fitting

- en877

- cast iron fitting

- union

- ductile cast iron pipe

- elbow

- tee

Recommended Products

- Anchor Brand UPVC Japanese Standard Industrial Drainage 92° Tee

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Elbow With Top Outlet

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Elbow With Side Outlet

- Anchor Brand UPVC Japanese Standard Industrial Drainage 45° Y-branch

- Anchor Brand UPVC Japanese Standard Industrial Drainage Reducing Sleeve (big-small Head)

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Reducing Tee

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Tee

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Single-threaded Tee

- Anchor Brand UPVC Japanese Standard Industrial Drainage 45° Elbow

- Anchor Brand UPVC Japanese Standard Industrial Drainage 90° Elbow

- Welded Seamless Carbon Steel Bend 1 Times 2 Times 3 Times 4 Times Special-shaped Processing

- Anchor Daily Standard UPVC Inner Tooth Joint

Find Similar Products By Category

- Construction & Decoration > Pipe Fittings > Tee

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

antoney zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

antoney zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile