Home > Products > Aluminum Bronze Alloys > C61000 Aluminum Bronze alloy flat bar

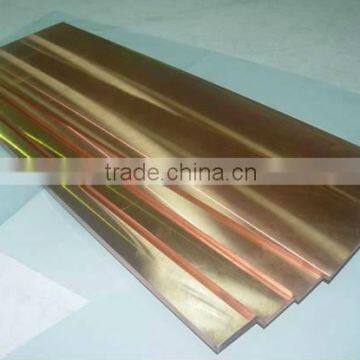

C61000 Aluminum Bronze alloy flat bar

- 30 Ton / Tons per Month

- Shanghai

- T/T Credit Card

You May Like

Product Details

| Place of Origin | Fujian, China | Brand Name | ALB-ALLOYS | |

| Model Number | C61000 | Application | Bushings bearings for aerospace industry | |

| Shape | Round bars, Flat bars, Square bars, Rectangular bars, Hexagon bars | Material | Aluminum Bronze Alloys | |

| Dimensions | ustom Diameter & Sizes | Chemical Composition | Al: 6.00-8.50% Fe: 0.50% Max. Si: 0.10% Max. Zn: 0.20% Max. Pb: 0.02% |

Product Description

Specifications

C61000 Aluminum Bronze alloy flat bar1.Competitive prices;

2.Advanced equipment;

3.Professional

4.ASTM,GB,JIS,DIN

C61000 Aluminum Bronze alloy flat bar

International Specification RFQ

C61000 Details & Applications:

C61000 Aluminum Bronze

CuAl8 – UNS.C61000 Aluminum Bronze Alloys, Nominally composed of 92% copper and 8% aluminum, which is known for its hardness, high strength, wear and corrosion resistance. Although it is an engineering alloy, its rich gold color also allows its use in decorative applications, and it has good hot and cold workability. So its applications including welding wire, bolts, tie rods, shafts, and pump parts.

Typical Application for C61000 Aluminum Bronze Alloys:

Architecture: Decorative Applications

Fasteners: Bolts, Nuts

Industrial: Tie Rods, Welding Wire, Shafts, Pump Parts, Overlay on Steel for Wearing Surface

Available Sizes:

Custom Diameter & Sizes, Random Mill lengths

Available Products (forms):

Round bars, Flat bars, Square bars, Rectangular bars, Hexagon bars

Custom shapes are available upon request.

Chemical Composition:

Al: 6.00-8.50%

Fe: 0.50% Max.

Si: 0.10% Max.

Zn: 0.20% Max.

Pb: 0.02% Max.

Cu: Balance

Note: Copper plus additions equal 99.50% minimum.

Typical Physical Properties:

Specific Gravity: 7.78 g/cm3

Coefficient of Thermal Expansion per °C: 17.80 x 10-6 (20-100°C)

Electrical Conductivity (% IACS): 15 % @ 68 F

Thermal Conductivity: 40.0 Btu • ft/(hr • ft2•oF)at 68F

Modulus of Elasticity in tension: 17000 ksi

Note:

1). the units are based upon US Customary.

2). the typical physical properties apply to age hardened products.

International Specification:

Rods/Bars: UNS.C61000, CDA610, AWS A.5.7 / Federal QQ-C-450

European Standards: CuAl8, DIN 2.0920

Note:

ASTM: American Society for Testing and Materials

RWMA: Resistance Welder Manufacturers' Association

Note: Unless otherwise specified, material will be produced to DIN & RWMA.

Contact Us

- ALB (Xiamen) Material Company Limited

- Contact nameLindy Chen Chat Now

- Phone0086-592-5631276

- AddressNo. 186 Huarong Road, Huli district, Xiamen, Fujian

Product Categories

New Products

-

DIN2.0290 Aluminum Bronze Bars

-

DIN2.0290 Aluminum Bronze Rod

-

DIN2.0290 Aluminum Bronze Round Bar

-

CDA610 Aluminum Bronze Round Bar

-

CDA610 Aluminum Bronze Bar

-

CDA610 Aluminum Bronze Rod

-

C61000 Aluminum Bronze Rod

-

C61000 Aluminum Bronze Bar

-

C61000 Aluminum Bronze Round Bar

-

UNS.C61000 Aluminum Bronze Round Bar

-

UNS.C61000 Aluminum Bronze Bars

-

UNS.C61000 Aluminum Bronze Rod

Popular Searches

- Magnesium Ingot

- Magnesium Alloy Ingot

- Magnesium Alloy

- gallium

- metallurgy

- anode

- Cu Sn Alloy

- magnesium

- magnesium plate

- Mg Ingot

- Magnesium Ingots

- germanium ingot

- cadmium

- ferro chrome

- Carbon Ferrochrome

- gallium metal

- Metal Cobalt

- ferro chrome alloy

- magnesium rod

- magnesium pipe

- magnesium alloy sacrificial anode

- magnesium alloy bar

- aluminum alloy sacrificial anode

- az91

- Metal Lump

- capacitor tantalum

- germanium

- zirconium rod

- zirconium tube

- zirconium bar

Recommended Products

- stainless steel seamless pipe

- 904L stainless steel seamless pipe

- Silicon Carbide resistors SiC resistors

- Electric heating molybdenum disilicide type L

- M Type Silicon Carbide Heating Elements

- Zirconia Sintering Furnace U shape MoSi2 Heating Element 1850C

- SiC heating elements-spiral groove Bar for higher temperatures (3000°F)

- Super pure 1850C MoSi2 heater heating element

- Dental Sintering Furnace U shape MoSi2 Heating Element For Zirkonzahn 600

- Dental zirconia Sintering furnace use Molybdenum Disilicide (MoSi2) Heating Elements

- 1900 Molybdenum Disilicide (MoSi2) Heating Elements for Dental zirconia sintering furnace

- 4j29 4j47 4j44 Low Expansion Iron Nickel Alloy Invar 36 Round Rod 4j36 Bar

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Black Metal & Products

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Lindy Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Lindy Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile