Home > Products > Band Saw Blade > Bimetal Reciprocating Saw Blades for Tough Metal

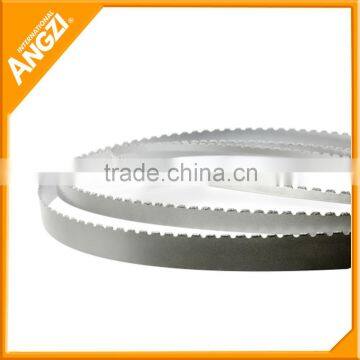

Bimetal Reciprocating Saw Blades for Tough Metal

- 889 Meter / Meters per Month

- Shanghai Ningbo Guangzhou ect

- T/T L/C D/P D/A Credit Card PayPal

You May Like

-

M42 multi purpose sawing blade for various applications

-

UBN-8 Band Saw Blade Welding Machine

-

Angzi UBN-8 Welder Tool For Bandsaw Producing Flash Butt Welding Machines

-

Program Controlled Semi Auto Falsh Butt Welder Electric Welding Machine Price

-

Semi-automatic Band Saw Welding Machine

-

UBN-8 Popular Machine 8 kva Adjustable Features Machine Welding

Product Details

| Place of Origin | Shanghai, China | Brand Name | Angzi | |

| Blade Material | HSS | Finishing | CrN | |

| Size | 34 x 1.10,41 x 1.30,54 x 1.60,67 x 1.60 |

Product Description

Bimetal Reciprocating Saw Blades for Tough Metal

Engineered for:

- Tough metal

Superior, because:

Tooth tips of HSS M42 / material no. 1.3247

The new designed special HL variable tooth with slightly positive rake angle and heavy group set shows excellent performance on H-beams and similar shapes. The PROFILER-SPRINT-VS avoids pinching in beams with inside tension, or in poorly supported profiles. For 90° and miter cutting.

| mm | inch | 2/3 | 3/4 |

|---|---|---|---|

| 34 x 1.10 | 1 1/4 x 0,042 | K | |

| 41 x 1.30 | 1 1/2 x 0,050 | K | K |

| 54 x 1.60 | 2 x 0,063 | K | K |

| 67 x 1.60 | 2 5/8 x 0,063 | K | K |

| K = Reinforced variable tooth | |||

Additional Information

Why so successful?

M 42

material no. 1.3247

hardness approx. 67-69 HRC

M 51

material no. 1.3207

hardness approx. 69 HRC, with high tungsten and cobalt content

Flexible:

The blade backer of our Bi-Metal Band Saw Blade consists of a special alloyed spring steel. Highly flexible at a hardness of about 50 HRC. The ideal basis for long fatique life and excellent cutting performance.

Hard and wear resistant:

Tooth tips made of hardened HSS-Steel in M42 or M51 quality.

Perfectly joint:

Both materials are undetachably welded together.

All advantages:

The high quality Bi-Metal band combines the flexibility of the spring steel backing with the enormous wear resistance of high speed steel. Each tooth tip of the finished band is of hardened HSS-steel, extremely durable for best performance.

Terminology

b = width of blade

s = thickness of saw blade

h = gullet depth

t = tooth pitch

a = rake angle

y = clearance angle

w = width of set

The right tooth for the right performance

Only correct choice of tooth forms allows efficient cutting with low vibration. Four basic types are available:

0 degree - Standard tooth = N

Designed for:

- short chipping materials

- light wall thickness

Data:

- rake angle 0°

- 4 to 18 tpi

Article groups:

100, 110, 420

Positive - Hook tooth = H

Designed for:

- long chipping materials

Materials

- large cross sections

Data:

- positive rake angle

- 2 to 6 tpi

Article groups:

100, 110, 421, 426, 427

0 degree - Variable tooth = K-0

Designed for:

- low vibration cutting

- - structurals

Data:

- rake angle 0°

- variable tooth pitch of 3/4 to 10/14 tpi

Article groups:

430

Positive - Variable tooth = K-POS

Designed for:

- low vibration cutting

- solid materials

Data:

- positive rake angle

- variable tooth pitch of 0,75/1,25 to 4/6 tpi

Article groups:

433, 442, 445 (K-V)

Constant or variable?

| Constant tooth pitch The tooth distance is equally spaced. The number of teeth per inch (25,4 mm) denotes the tooth of the saw blade. |

| Variable tooth pitch The tooth distances vary within a group of teeth. The smallest and the largest tooth pitch denotes the variable tooth of saw blade. |

What groups and waves can cause.

Apart from tooth pitch and tooth form the exact set is essential for the performance of the sawblade. The correct clearance of back is achieved by the specific set for the cutting application. This is to avoid blade pinching, very important in problematic cutting jobs. Width and type of set are tuned to the cutting application:

Correct tooth pitch – optimum performance.

The choice of the right tooth pitch can be decisive to achieve the optimum performance to cut the relevant cross section. Choose either Standard tooth with constant tooth pitch or Variable tooth with unevenly spaced teeth. It is advisable to use Variable tooth to cut problematic workpieces to reduce vibrations.

Recommendation for cutting solid material

| Constant tooth pitch | ||

|---|---|---|

| Cross section | Teeth per inch | |

| mm | tpi | Tooth shape |

| 200 - 400 | 2 | H |

| 120 - 200 | 3 | H |

| 80 - 120 | 4 | H/N |

| 40 - 80 | 6 | H/N |

| 20 - 40 | 10 | N |

| 10 - 20 | 14 | N |

| up to 10 | 18 | N |

| N = Standard tooth H = Hook tooth | ||

| Variable tooth pitch | ||

|---|---|---|

| Cross section | Teeth per inch | |

| mm | tpi | Tooth shape |

| over 550 | 0.75/1.25 | K |

| 380 - 750 | 1/1.5 | K |

| 250 - 550 | 1.4/2 | K |

| 120 - 350 | 2/3 | K |

| 80 - 140 | 3/4 | K |

| 60 - 110 | 4/6 | K |

| 40 - 70 | 5/7 | 5/8 | K |

| 30 - 60 | 6/10 | K |

| 20 - 40 | 8/11 | 8/12 | K |

| up to 25 | 10/14 | K |

| K = Variable tooth | ||

Q: Can I have your quotation?

A: First, please inform us which material you would like to cut and its details includes size cutting in one time, solid or hollow, circular or rectangular,ect., without these parameters, we are not able to recommend you the suitable machine.

Q: What is the voltage and Hertz in your country?

A:In China,the Voltage is 380V(3 Phase),the Hertz is 50HZ, we can change the voltage and Hertz according to your requirement(also have 220V)

Q.Your price seems a little high?

A: You get what you pay for, our price is based on good quality,we sell the machines all over the world with good feedback from our customers, and we don't sell the machine with low configuration, cause it will trouble us more in the future maintenance.

Q: If OEM and ODM services available?

A: Yes. We can make the machines with customers' brand and logo. With professional engineers,we can also design and produce the machines according to customers' requests.

Q:What about the lead time for mass production?

A:Honestly,it depends on the order quantity and the season you make the order,always 13-29 days, and many models of band saw machine have stock

Q:What about the payments

A:We usually accept 30%TT for deposit and 70%TT before shipment.

Q:What is your terms of delivery?

We accept EXW, FOB and CIF,you can choose the one which is the most convenient or cost effective for you

Q.What about the shipping ways?

A:We will choose the sea transportation,and if you want the blade saw,

we will choose the express like DHL,UPS,ect. or other shipping ways according to your requirement

Contact me,let's talk details!

Contact Us

- Shanghai Angzi Machinery Equipment Co., Ltd.

- Contact nameGrace Lan Chat Now

- Phone86-021-39003396

- Address1st Floor, No. 440, Lane 5000, Baoqian Road, Waigang Town

Product Categories

New Products

-

Program Controlled With 3C Certification 8KVA Band Saw Welding Machine

-

Best Selling Cheap Price Small Welding Machine

-

Upsetting Pressure And Annealing Time Can Be Operated Easilly Outside Adjustment High Frequency Welder For Sale

-

Semi Auto Electric Welder Essential Tool For Blades Mill Butt Welding

-

UBN 8 Flash Butt Welder Semi Automatic Electrical Welding Tape

-

Self Control Between Welding And Annealing Semi Auto Flash Electric Welding Tools

-

High Frequency Flash Butt Welding Machines

-

China Factory Saw Blade Small Electric Welder

-

Low Cost Electric Welding Machine Price

-

Bi-metal Band Saw Blades Butt Welder

-

Angzi UBN 8 Flash Semi Auto Electronic Welding Machine

-

UBN-8 Without Any Welding Flux Precise Setting Electrofusion Welding Machine

-

UBN-8 Mosel For Bandsaw Blade For Metalworking Used Butt Welding Machine

-

Most Popular Saw Blade Electric Welding Machine

-

Perfect butt join bimetal saw blade welder

-

Economical Pricing Zhejiang New Critical Parts Used Welding Machines

-

For Popular Parameters Band Saw Blades Flash Butt Electric Welding

-

No need For Any Welding Flux Easily Operated Adjustable Welding Temperature Bandsaw Blade Welding

-

China Original Band Saw Blade Welding Equipment

-

Precise setting flash band saw welding machine

-

3C butt fusion machine for band knives

-

Bandsaw Blade Flash Butt Welding Machine

-

Highly Demanded Butt Welder For International Market Semi Automatic Mode Electronic Fuse Types

-

Angzi Welder Economical Pricing For Thin Strip Shears Welding Parts

Popular Searches

- diamond tool

- cutting tool

- diamond blade

- saw blade

- Diamond Saw Blade

- carbide tipped blade

- circular blades

- cutting tools

- blade

- Aluminum Alloy Blade

- Circular Saw Blade

- Other Tools

- laser tool

- cutting blade

- band saw blade

- stainless steel blade

- Triple Blade

- cutting blades

- saw blades

- flat blade

- ceramic disc

- angle grinder saw blade

- concrete tools

- diamond tools

- diamond disc

- diamond concrete blade

- Concrete Cutting Tool

- Saw Blade Tool

- Disc Blade

- Head Blade

Recommended Products

- Diamond grinding disc ground cement stone grinding disc concrete processing Angle grinding floor polishing grinding wheel

- Sponge knife strap

- TCT saw blades for single chip

- TCT grooving saw blades

- TCT thin-kerf cutting saw blades

- Conical scoring saw blades

- TCT panel sizing saw blades

- TCT adjustable scoring saw blades

- TCT universal saw blades

- PCD router bit

- PCD aluminum saw blades

- PCD panel sizing saw blades

Find Similar Products By Category

- Industrial Equipment & Components > Cutter & Tongs > Saw Blade

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Grace Lan

Hi there! Welcome to my shop. Let me know if you have any questions.

Grace Lan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile