Home > Products > Feed machine accessories > China Widely Exported Ring Rolling Forging

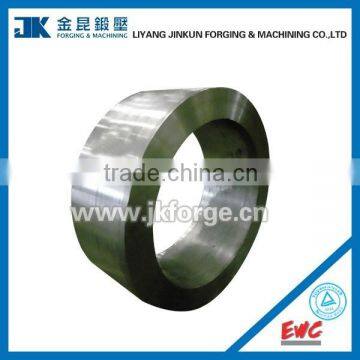

China Widely Exported Ring Rolling Forging

- Shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Type | Other, ring die blank | Use | Other, Pellet machine | |

| Place of Origin | Jiangsu, China | Brand Name | Jinkun | |

| Model Number | JK460 |

Product Description

China widely exported ring rolling forging

Feature :

1. Widely used scope :Spare parts both for animal feed and biomass pellet machine, such as Open roller shell, closed roller shell, Concave type ring die blank , Cylinder type ring die blank, Main shaft ,Air shaft ,Hoop and etc

2. Materials :4Cr13,20CrMnTi,16MnCr5,GCr15,40Cr,608izMn ,20CrMn and etc

3. Strong machining & heat treatment abilities

4. Customized designed ,processing follow drawing ;

5. Certification by nine classification society ,such as BV,ABS and etc ;

6. After-sale guarantee: One year warranty and all round after sale service

7. Capacity: From 10kg-10000kg for all forge follow drawing

8. Delivery on time

Ring rolling forging

Parts of Specification list

Model | Outer diameter (mm) | Inner diameter (mm) | Width (mm) | N.W (KG) | G.W (KG) |

JK42 | 510 | 420 | 206 | 106.4 | 165 |

CPM3016 | 510 | 407 | 190 | 110.7 | 168 |

JK460 | 560 | 460 | 185 | 116.4 | 190 |

JK500 | 600 | 500 | 190 | 129 | 215 |

JK508 | 620 | 508 | 238 | 185.5 | 291 |

JK600 | 670 | 550 | 235 | 212.3 | 325 |

Remark :More specification please contract with us .

Production flow

1. Raw materials

We purchase all kinds of raw materials based on clients’ requirement on forge pieces.

2. Inspection of raw materials

We check,re-examine and reserve sample of raw materials in each furnace.

3. Blanking Process

Based on the weight of blanks ,we select billet with corresponding standard for saw cutting.

4. Metal heating process

We heat materials blocks to make it reach initial forging temperature

5. Forging process

During the forging process ,blank entirely undertakes straight line impacts of electro-hydraulic hammer ,where its internal textures received enough impacts and extrusions to crush large grains into small ones to enhance density and eliminate loose cast condition of metal with large amount of plastic flows so as to change the blank into desired metal product of certain shape ,size and mechanical property .

6. Preheat treatment process

Heat treatment after forging can eliminate stresses,as well as improve quality of the workpiece.

1. For easy cutting process,rigidity of forge piece is adjusted (HB170-250);

2. Residual internal stress of ofrge piece is eliminated to avoid transformation and cracking of the workpiece

7. Machining process

Based on drawing ,coarse and precise processing is conducted to meet the workpiece requirement .

8. Product inspection

We inspect the appearance ,size ,rigidity and flaw detection of processed workpiece.

9. Package

We pack and bin the finished products for shipment .

About us

Liyang Jinkun Forging and machining Co.,Ltd was founded in 1996 ,with a total coverage of 80 thousands square meters ,which majored in metal materials forging ,heat treatment and machine machining .

Our main products refer to wind power generation,rail transit, animal feed machine ,shipbuilding, Pressure vessel manufacturing and etc .

At present,we have equipment with the yearly forging production of 60 thousand tons.

Warehouse

About service

By thoroughly tempered with strict disciplines, and regard quality as essential and customer first .Jinkun is committed to provide more high-quality product quality, more stable product performance, more perfect service system, more efficient after-sales channels, continuously forging itself, pioneering and innovative, to serve more international famous customers and go forward, and to provide more help for customer service system .

Certification

1.The quality assurance system of JINKUN is authenticated with ISO9001 quality assurance system.

2.The products of JINKUN are issued PED certification by European Union.

FAQ

1.Q:Are you a factory or a trading company?

A:We are factory and trading company integration .

2.Q:Where is your factory's location?

A:Our factory is located in xiangshan road no. 388 North Kunlun Road, Liyang City, Jiangsu Province, China, very near to Shanghai and Nanjing.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How does your factory do regarding quality control?

A:"Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained PED authentication.

4.why choose our products?

A:"Good products! Good reputation! Good service! Good price! "

Contact Us

- Liyang Jinkun Forging & Machining Co., Ltd.

- Contact nameCindy Chen Chat Now

- Phone0086-519-87337542

- AddressNo. 388, Kunlun North Road, Licheng Town

Product Categories

| Engineering machinery accessories | Feed machine accessories | Harbor machinery accessories | New Products |

| Rail transit accessories | Wind power accessories |

New Products

-

China Wildly Exported Bearing Block With BV Authentication

-

Best Sales in Europe Driving Gear With High Quality

-

Factory Directly Supply Transmission Shaft

-

High Quality Planet Gear With Different Specification

-

Hot Sales Forging Gear Wheel for Wind Power

-

Factory Directly Supply Forging Gear With Best Price

Popular Searches

- rubber track

- agricultural rubber track

- agricultural inner tube

- bias agricultural tire

- farm tire

- utv tire

- spoke wheel

- market survey

- cylinder head cleaning

- pto

- tractor part

- sprayer gun

- wheelbarrow tire

- trailer rim

- trailer wheel

- snow blade

- trailer wheel rim

- corn seeder

- potato seeder

- vegetable seeder

- maize seeder

- rice seeder

- soybean seeder

- tractor tire

- trailer tire

- wheelbarrow tyre

- agricultural tire

- agricultural tractor tire

- wheel barrow tire

- well logging

Recommended Products

- Baler Parts Needle Roller 0008173701 Fit Claas Quadrant 2200 1100 3200

- Trip Arm Bolt 002162 Locking PIN Shaft Fit CLaas Baler 2200 1100 2100 Markant 55

- Agricultural Machinery Parts 0013124633 Flange Bearing for Silage Machine Claas Quadrant 3300 5300

- Claas Quadrant 2200 Baler Parts Bracket 000056.0

- Claas Quadrant 2200 3200 Agricultural Machinery Flange Bearing 8261150 Silage Machine Parts for Big Square Balers

- 971894 0009718941 971 894.0 Bearing Flange Fits Claas Quadrant 2200 3200

- 0008166501 Knotter Clamping Plate for Claas Quadrant 2200/3200 Combine Harvester

- New Product 2% UV Resistant Outdoor Conductive Livestock Electric PolyWire Fence Poly Ropes

- Gasoline Generator Accessories Oil Outlet Nozzle 2kw 6.5KW 3kw 168F External Wire Internal Thread Fuel Tank Switch

- Gasoline Engine Stop Switch Flameout Switch 170168 Engine Pump Micro Tiller Sprayer Stop Switch

- Tractors Are Equipped With Anti Trap Half Chain Rails, Solving the Problem of Stuck Vehicles With Just One Click

- Upgrade the Performance of the Deere Harvester, With Large Track Type Triangular Wheels Capable of Making Circles

Find Similar Products By Category

- Manufacturing & Processing Machinery > Agricultural Machinery > Agricultural Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Cindy Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Cindy Chen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile