Home > Products > Ball mill For Hard Material > Factory direct supply low price ball mill

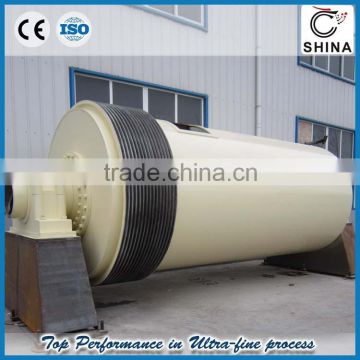

Factory direct supply low price ball mill

- 20 Set / Sets per Month

- Qingdao Port

- T/T

You May Like

Product Details

| Condition | New | Type | Ball Mill | |

| Motor Type | AC Motor | Place of Origin | Shandong, China | |

| Brand Name | SHINA | Model Number | production line | |

| Dimension(L*W*H) | different | Weight | different according to size of machine | |

| Certification | CE cerficated,ISO9001:2008 | Warranty | 18 months | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Factory direct supply low price ball mill

WHAT WE CAN DO FOR YOU:

The scope of work

- Investigation, characterization and evaluation of raw materials and products

- Consulting in plant modifications, techniques and improvements to reach the market requirements

- Development of new processing technologies and techniques including tests of mechanical, thermical and chemical processes

- Project management for plant modifications with commissioning and training of customer’s staff

- Design and project planning of plants including the engineering and specifications for local supplies

- Consultancy in final product applications and assistance for marketing international

Project Step

Step 1: Feasibility study

In this phase, the effort is to get a rough overview of budget, design, time schedule and economic efficiency of the project. Hereby is given a first and crucial opportunity of a project decision according to the terms of profitability and feasibility.

Step 2: Project preparation

This phase includes process and process steps definition (important for interfaces), pre layout, budget, time schedule, procurement, processing tests, selection of co-operation partners, financing and permitting. Here is given the second opportunity of a project decision.

Step 3: Project realisation

In this phase the project will be realized by us by managing the whole project, comprising the final design, budget, time schedule, interfaces, construction work, etc. up to the start-up in dependence on the terms of contract. Also in this phase, it is important to evaluate the human resources and to hire and train the operational staff.

Our technology group have more than ten years' experience.

Also our after-sales service engineer group also are very experienced on installation, commissioning and text-run.

They also will training customers' workers.

some of customers' reference:

FEATURES

- special design for feed material with high hardness

- Low speed, low abrasion

- best ratio of length and diameter ,no over-grinding

- Low energy consumption, no pollution

- feed at even speed, higher grinding effiency

Scope Of Application

quartz, zircon sand etc.

size of ball mill Parameters | Ø1.8X4.5m | Ø2.2X4.8m | Ø2.4X4.5m | Ø2.6X5.5m | Ø3.0X6m | |

motor power kw | 90 | 132 | 160/185 | 200/250 | 380/400 | |

D97:45um | classifier model | ATP315 | ATP400 | ATP500 | ATP570 | ATP750 |

Quartz production t/h | 1.1 | 1.8 | 2.5-3 | 4-4.5 | 6 | |

Zircon sand production t/h | 1.3 | 2.0 | 3-3.5 | 4.5-5 | 6.5-7 | |

D97:10um | classifier model | ATP315 | ATP400 | ATP315/3 | ATP315/4 | ATP315/6 |

Quartz production t/h | 0.2 | 0.35 | 0.45-0.5 | 0.6 | 0.8-1 | |

D50:1-1.5um | classifier model | ATP315 | ATP315/3 | ATP315/3 | ATP315/4 | ATP315/6 |

Zircon sand production t/h | 0.15 | 0.3 | 0.4 | 0.55 | 0.8-1 | |

Note: 1. the above data is based on feeding size is 40~100mesh.

2. different material from different disctrict has different characteristics, so, the capacity will also be different accordingly

3. the above data only depends on two traditioanl material with high hardness, if other material, please contact me freely for consultant

Quality guarantee is for 18 months. During 18 months, if there is any problem or destroy (non-artificial damage), we will repair or change for free. After one year, if there is any problem, we will still supply good service, and we will charge cost if parts needed to be changed.

1. Flow sheet of the process

2. Electrical interlocking sequence

3. Dimension drawings for supplied equipment

4. Operation manuals

5. Technical information and specification for local supply

6. Engineering drawings for local supplies

7. Technology data and drawings for installation and commissioning

8. Spare parts list

Q &A:

1. Why choose QINGDAO SHINA as supplier?

A: QINGDAO SHINA has a perfect team with more than 20 years experience. Technology of QINGDAO SHINA is original from Germany. What customers get from QINGDAO SHINA is not only one set of machine, but together with know-how.

2. What should I do if I want to start a new project or extent production, but I have no idea what should I do at the beginning?

A. Please send email to QINGDAO SHINA and tell QINGDAO SHINA your situation of the project, QINGDAO SHINA will supply one feasibility study report together with detailed proposal and technical suggestions only for your project.

3. How about the quality of machine manufactured by QINGDAO SHINA?

A. QINGDAO SHINA business concept is: “Start a career with essence, win through high quality”. QINGDAO SHINA follows the principle of “quality is most important” when manufacturing each machine. Besides, QINDAO SHINA decides to lengthen quality guarantee of each machine or production line to 1.5 years so that customers can use machine without worry.

4. How about the after-sales service of QINGDAO SHINA?

A. QINGDA SHINA has a good after-sales service team, all the engineers in the team has more than 10 years experience. QINGDAO SHINA can promise that after the machine arriving at customer’s factory, we will arrange our engineer in time accordingly to make installation. Commissioning and test run. QINGDAO SHINA’s customer service concept is: customers are always the first!

5. How can I start the machine when getting machine?

A. QINGDAO SHINA will arrange engineers with rich experiences to customer’s factory for installation, commissioning and test run. After then, engineers will make training for workers about how to start machine or production line until workers can start machine very good alone.

6. If there are some problems or questions during running machine or production line, what should I do?

A. Please call QINGDAO SHINA in time if you have any questions during production. QINGDAO SHINA will reply customers in time to make sure the production won’t be delayed.

Contact Us

- Qingdao Shina Machinery Equipment Co., Ltd.

- Contact nameRachel Cui Chat Now

- Phone0086-532-87761880

- Address46 Yantai South Road, Laxi, Qingdao, Shandong

Product Categories

New Products

-

2015 Energy-saving ball mill for sale

-

ball mill in Pakistan

-

Big capacity and high effficiency ball mill

-

China super performance good quality ball mill price

-

2016 Hot Sale Ball Mill / Ball Grinding Mill / Ball Mill Prices

-

Good performance best selling quartz grinding ball mill from China

-

horizontal ball mill for quartz for sale with higher capacity

-

Ball mill classifying production line quartz stone machine

-

Germany Technology quartz milling machine rock crushing plant

-

Germany Technology quartz sand ball mill

-

Ball mill classifying production line quartz stone powder making machine

-

Low Energy Consumption Grinding Ball Mill for hard material

Popular Searches

- Graphite Material Powder

- Graphite Carbon Expandable Powder

- Petroleum Coke Cpc

- copper graphite

- Pet Coke Recarburizer

- high purity graphite powder

- Carbon Flake Graphite

- Coating Graphite

- Refractory Use Graphite

- Gray Powder

- thermal graphite

- Sheet Graphite

- Anthracite Carburizer

- Sulfur Gpc Graphite

- Carbon Powder Graphite

- natural costing

- crucibles graphite

- Expandable Packing Graphite

- disc bowl

- Carbon Graphite Additive

- Powder Cpc

- Anode Powder

- Additives Graphite

- all mill

- an mill

- at mill

- a d grind

- ball coal

- ball line

- be mill

Recommended Products

- Yosion Technology YXRM-5A-1850 Bottle Roller; Rod Mill;Fine grinding samples

- Sand Making Machine

- CRONUS Ring Roller Mill Industrial Grade Powder Processing Equipment

- Raymond Mill YGM/CLGM Series Calcium Carbonate/Talc/Gypsum Ultrafine Grinding Machine Industrial Grade

- Energy-saving and environmentally friendly Raymond Mill YGM/CLGM Series Calcium Carbonate/Talc/Gypsum Ultrafine Grinding Machine Industrial Grade

- CRONUS New Environmentally Friendly Ring Roller Mill Industrial Grade Powder Processing Equipment

- 【CRONUS Brand】Large ring roller mill Ore crusher Industrial grinding equipment

- CRONUS High-efficiency Energy-saving Ring Roller Mill Calcium Carbonate/Quartz Stone Special Ultrafine Powder Processing Equipment

- Factory direct supply CRONUS Ring Roller Mill 200-3000 mesh crusher non-metallic mineral grinding machine

- Raymond Mill Pendulum Grinding Mill Quartz Limestone Kaolin Calcium Carbonate Gypsum Grinding Raymond Mill Machine

- Limestone Raymond Mill for Stone Rock Calcium Carbonate YGM/CLGM Micro Powder Grinding Machine for Stone

- Small Limestone Raymond Mill for Stone Rock Calcium Carbonate YGM/CLGM Micro Powder Grinding Machine for Stone

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Mining Mill

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Rachel Cui

Hi there! Welcome to my shop. Let me know if you have any questions.

Rachel Cui

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile