Home > Products > Steel plate blast & painting machine > QXY2000 Automatic steel plate pretreatment line

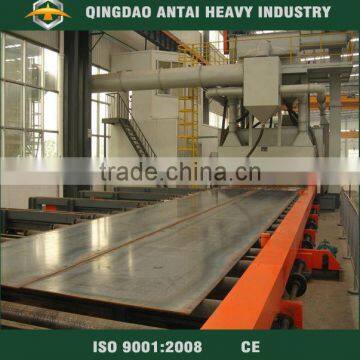

QXY2000 Automatic steel plate pretreatment line

- Qingdao

- T/T

You May Like

-

Shot blasting machine for steel plate and painting and drying line

-

QXY2500 Steel plate shot blasting and painting machine/shot peening machine

-

stainless steel pipe shot blasting machine

-

H beam shot blasting machine for surface treatment

-

cleaning machine/H beam Shot blasting machine HHH36

-

Multifunctional Auto Q69 Steel Plate Shot Blasting Machine/shot blaster for sale for Steel Plate

Product Details

| Place of Origin | Shandong, China | Brand Name | Antai | |

| Model Number | QXY2000 | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Specifications

1.roller conveyor type2.preheating.blasting ,painting&drying.

3.fully automatic

4.specially designed for steel plate

Qingdao Antai Heavy Industry Machinery Co., Ltd.

Founded in 2003, 10 years experience for making shot blasting machine.

A group company,having real estate, machinery and leather bags industry.

Eight experienced engineers to consider every possibility for customers.

Three of them has over 25 years knowledge of shot blasting technology.

3D software for auxiliary design. Show every design details in front of you.

Experienced technicians for production, installation, commissioning & service.

ISO 9001:2008 certified company, CE certificate will be issued soon.

All machining parts out sourced from professional CNC machining company with strict quality control procedure.

Own foundry to produce special material spare parts for our machines.

Shot blasting machine

Specially designed for blasting steel plate, sectional steel, beams or structure.

Shot blasting machine for steel plate, section steel, beams, bars is designed and produced by adopting the advantages of similar products from both within the country and abroad.

The rusting cleaning part (shotblast cleaning) adopts high-efficient blast wheel and full shutter type shot sand separator.

The sweeping machine adopts specially made high-strength nylon rolling brush and high-pressure ventilator. The preheating and drying part may adopt various heating methods. The paint spraying part adopts high-pressure airless spraying method.

The complete set of equipment is controlled by PLC, and is the large-size complete equipment of international advanced.

It is mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of steel plate and various structural sections, as well as for cleaning and strengthening of metal structural parts.

Technical Specification:

Machine Model: QXY2000

1. Width of steel plate: 2000 mm

2. Inlet opening: 2200 * 600mm

3. Length of steel: 1200-12000 mm

4. Roller speed: 0.5-4 m/min

5. Thickness of plate: 3-60 mm

6. Quantity of turbine: 4 sets

7. Motor power of turbine: 22Kw * 4

8. Abrasive cleaning: rolling brush and blowing device

9. Dust collector: cartridge type dust collector

10.Power consumption:380kw

Other models:

QXY2000 | QXY3000 | QXY4000 | QXY4500 | |

Entrance Dimension | 2100x400mm | 3100x600mm | 4100x600mm | 4600x600mm |

Turbines | 4 | 6 | 8 | 8 |

Turbine Power | 15KW | 22KW | 22KW | 30KW |

Conveying Speed | 0.5~4m/min | 0.5~4m/min | 0.5~4m/min | 0.5~4m/min |

Blasting Speed | 0.5~2m/min | 0.5~2m/min | 0.5~2m/min | 0.5~2m/min |

Surface Cleaning Grade | SA 2.5 | SA 2.5 | SA 2.5 | SA 2.5 |

Surface Roughness | 40~70μm | 40~70μm | 40~70μm | 40~70μm |

Conveyor Loading Capacity | 1,500Kg | 2,000Kg | 2,000Kg | 2,500Kg |

Air consumption | 5~7m³/min | 5~7m³/min | 5~7m³/min | 5~7m³/min |

Dust Collector | Filter Cartridge | Filter Cartridge | Filter Cartridge | Filter Cartridge |

Notice:

According to your requirements,the most suitable machines will be designed for your workpieces please indicate the folloing details.

1.what kind of workpiece will you clean ?

2.The workpiece size,length ,width and height of maximum workpiece?

3.How many workpiecs do you want to clean per day ?

Based on this question,the detailed technical proposals will be sent to you for reference.

1.Production time of 40 days shot blasting machine

2.Installation and commissioning time:20 days

3.installation and commissioning issue:Antai will send 1-2 technicians to help with machine installation

and commissioning for our shot blasting machine,customer pays for their tickets,hotel and diet Salary is USD

70 per day per person.

4.warranty time of shot blasting machine:12 months from date of commissioning completion,but no more

than 18 months from date of delivery.

5.Payment term:30% as down payment,70%balance at sight of B/L copy before delivery

6.Antai supply full english (or Russian)documents,including general installation drawing,pit design drawing,

manual book,electric wiring diagram,electric manual book and maintenance book ,etc .

Contact Us

- Qingdao Antai Heavy Industry Machinery Co., Ltd.

- Contact nameyan Ji Chat Now

- Phone86-0532-88138566

- AddressShanghaidongyi Street No297,Jiaonan City,Qingdao City, Qingdao, Shandong

Product Categories

New Products

-

stainless steel pipe polishing machine/ shot blasting machine

-

International Brand Effective HHH-37 H Beam shot blasting machine/Shot Blast Equipment

-

cleaning machine/H beam Shot blasting machine

-

Q69 series steel plate shot blasting machine/Qingdao

-

Q69 steel shot blasting machine/steel pipe inner walls shot blast cleaning machine

-

stainless steel pipe making machine/steel pipe shot blasting machine

-

Q69 steel profile sand blasting machine/Q69/QH69/QG/Q38/Q48

-

Q69 Shot blasting machine for steel plate/steel shot blasting machine

-

H beam shot blasting machine for H beam cleaning

-

Auto Steel Plate Shot Blasting Machine for Steel Plate/auto pipe fabrication

-

hook shot blasting machine/hook lift containers for sale

-

Hook Shot Blasting Machine/hook shot blasting machine

-

External Steel Pipe Shot Blasting Machine/Shot Blasting Machine Price

-

Steel shot blasting and painting machine

-

Steel pass through type shot blast machine

-

Automatic steel plate shot blasting machine

-

steel plate shot blasting cleaning machine

-

Steel plate shot blasting painting machine

-

QH69 roller shot blast cleaning machine

-

Q69 roller shot blasting and cleaning machine

-

QH69 leading steel plate shot blasting machine

-

High quality pass-through shot blasting and painting machine

-

Roller conveyor shot blasting machine manufature

-

Automatic steel plate shot blasting painting machine(2500*800)

Popular Searches

- spare parts

- machine parts

- cnc machining

- garden shear

- Spare Part

- belt sander

- riveting machine

- air shear

- Aircraft Parts

- aluminum parts

- machinery part

- precision machining

- cnc parts

- aerospace machining

- cnc turning part

- Cnc Machining Part

- Machine Part

- Aluminum Cnc Machining Part

- Cnc Machine Part

- Cnc Precision Machining Part

- Machined Metal Part

- Cnc Milling Part

- Cnc Turned Part

- Repair Part

- Package Part

- Machine Spare Part

- Replacement Part

- aluminium heatsink

- plastic part

- lead alloy

Recommended Products

- Yinfeng 0.8-10mm Automatic Spring Coil Grinding Machine

- drum wood chipper price quality Low Noise, High Power

- drum wood shredder manufacturer auto Eco-Friendly Green Energy

- wood crusher price quality Municipal Waste Management

- wood chipper manufacturer tree trunk Fast ROI for Biomass Plant Operators

- Replaceable knives wood crusher quote Fast ROI for Biomass Plant Operators

- wood shredder price tree branches Emergency Stop & Overload Protection

- wood shredder manufacturer digital Compact Design

- drum wood chipper manufacturer quality Ideal for Forestry, Farms

- Replaceable knives wood shredder diesel drive Heavy-Duty Chipping

- Replaceable knives wood chipper moveable type Chips Ready for Compost or Boilers

- drum chipper price tree trunk Built to Last

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallurgy Machinery

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

yan Ji

Hi there! Welcome to my shop. Let me know if you have any questions.

yan Ji

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile