Home > Products > Refractory for Steel Plant > Refractory Silica Brick for Hot Blast Furnace

Refractory Silica Brick for Hot Blast Furnace

- Tianjin Qingdao Shanghai

- T/T L/C D/P D/A Credit Card

You May Like

-

Magnesia chrome bricks for AOD,VOD,RH and cement/glass industry

-

chrome magnesite refractory brick for rotary kiln lining

-

Blast furnace lining spalling with anti stripping high quality sillimanite bricks

-

Refractory low creep andalusite brick for hot blast stoves HBS

-

Bauxite Neutral Material Blast Furnace Refractory Brick

-

Reheating Furnace Industrial Bricks Furnacey Use Chrome Corundum Block

Product Details

| Place of Origin | Henan, China | Shape | Brick | |

| Material | Other, SiO2 | SiO2 Content (%) | ≥95 | |

| Al2O3 Content (%) | ≤1.0 | |||

| Model Number | Refractory Silica Brick for Hot Blast Furnace | Brand Name | DD |

Product Description

A brief introduction of refractory silica brick for hot blast furnace

Silica brick is a kind of acid refractory mainly made from tridymite, cristobalite and a small amount of residual quartz as well as glass phase. The raw material is natural silica sand whose SiO2 content should be more than 96%. The higher SiO2 content in silica sand, the higher temperature silica bricks resist. Silica bricks are used in the roof and superstructure of glass melting tanks as well as for hot repairs.

Our silica brick advantages

--Adopts high quality silica and advanced technology, our silica bricks enjoy the advantages of high purity, long service life, good thermal conductivity, high refractoriness under load, and good creep resistance.

--In addition, it has accurate size tolerance, pure color and luster appearance.

--Because of the good thermal shock resistance of silica brick, it is mainly used in the continuous operating furnace.

--Supporting the use of other high quality refractories, our silica brick can extent the service life of float glass furnace to 8 years and double the service life of bottle glass furnace.

Physical properties and chemical composition

Items | Arch Crown / Furnace wall | Checker Brick |

SiO2,% ≥ | 95 | 95 |

Cold Compressive Strength,Mpa ≥ | 35 | 30 |

Apparent Porosity,% ≤ | 22 | 23 |

Bulk Density,g/cm3 ≤ | 2.35 | 2.35 |

Thermal Expansion,% ≤(1000ºC) | 1.26 | 1.26 |

Creep Rate,%(0.2Mpa,1550ºC*50h) ≤ | 0.8 | 0.8 |

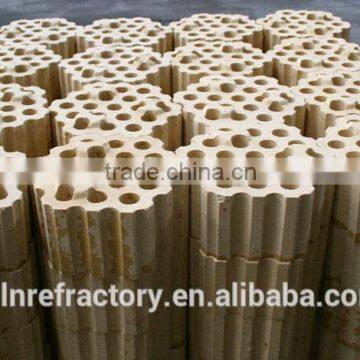

Silica Brick for Air Heating Furnace

1.Widely used in hot blast stoves.

2.Used in high temperature sections of the checker chamber in hot blast stoves.

3.Used as low-cost alternative to andalusite and mullite checker bricks in hot blast stoves.

4.High refractoriness, average thermal shock resistance makes it suitable in consistent temperature environment.

Refractory Silica Brick for Hot Blast Furnace Packaging & Shipping

Contact Us

- Zhengzhou Dengda Electric Melting Charging Co., Ltd.

- Contact nameCindy Tan Chat Now

- Phone86-371-55950822

- AddressXinmi, Chaohua Town, Zhengzhou, Henan

Product Categories

New Products

-

High Quality Chrome Corundum Refractory Bricks for Sale

-

Reheating Furnace In Steel Industry Use Chrome Corundum Refractory Brick

-

Chrome corundum refractory brick using in high temperature kilns

-

fire refractory brick for continuous casting

-

Silica Checker Brick in High Quality for Hot-Blast Stove

-

Good Thermal Shock Resistance Chrome Corundum Refractory Brick

-

SK32 SK34 SK36 SK38SK40 high temperature high density fire clay steel ladle refractory bricks

-

Top Grade Bauxite Based High Alumina Refractory Brick for Hot Blast Stove

-

Silica brick for hot blast stove refractory material price manufacturer

-

refractory silica brick

-

factory best selling acid refractory silica bricks from china

-

Refractory silica brick for coke oven furnace

-

High Grade Silica Refractory Brick For Glass Furnace

-

Manufacturer Silica Checker Brick with Irregularly-shaped Hole Used for Hot-Blast Stove

-

Refractory Furnace Crown Silica Brick for Blast

-

Used for Hot Blast Stove Low Thermal Expansion Silica Checker Fire Bricks

-

Standard Silica Brick in High Quality for Hot-Blast Stove

-

New! Acid refractory bricks silica bricks,silica fire brick,fused silica brick\silica bricks for blast furnace and oven

-

Hot sale ! refractory for furnace silica fire brick

-

High Density High Thermal Conductivity Silica brick,Silicon refractory fire brick for steel, glass industry

-

High strength light weight silica refractory brick for hot blast furnace

-

Silica Bricks for Hot Blast Stove

-

Refractory high temperature silicon carbide board SiC plates

-

China Sk32 Sk34 Sk36 Refractory Fire Clay Brick Factory with Good Price

Popular Searches

- refractory material

- tabular alumina

- calcium silicate product

- spinel

- coal tar pitch

- boron

- refractory brick

- firebrick

- clay brick

- alumina brick

- fire brick

- magnesia carbon brick

- high alumina brick

- insulation brick

- silica brick

- mullite brick

- fire clay brick

- fireclay brick

- lining brick

- building glass block

- graphite electrode

- ceramic fiber heater

- aluminum silicate blanket

- slag

- clinker

- refractory cement

- high alumina cement

- calcium aluminate cement

- graphite block

- iron powder

Recommended Products

- Wholesale High Quality High Alumina Bricks Engineered for Long Lasting Furnace Protection

- Wholesale High Quality High Alumina Bricks Engineered for Long Lasting Furnace Protection

- Wholesale 230 mm Size of Refractory High Alumina Fire Resistant Brick Used for Kilns

- Customization SK30 32 34 36 Refractory Brick High Alumina Bricks Fire Brick for Kiln Furnaces

- New Materials Manufacturer Alumina Bubble Insulation Brick Alumina Hollow Ball Insulating Refractory Brick Kiln

- Custom Size Fire Bricks High Alumina Light Insulation Brick for Kiln Furnace

- High-Temperature Lightweight refractory Mullite Insulating Brick with Mullite Fibers Cutting Service Available Fast Delivery

- Hot Selling Suitable Price Alumina Refractory Brick Clay Insulation Fire Brick for Furnace

- New Design High Density Mullite Heat Storage Bricks Honeycomb Ceramics for Aerospace Applications

- Unshape Monolithic refractory High Alumina Refractory Castable for 2025 New Refractory Industry

- Factory Custom Quality Controlled Silicon Nitride Bonded Silicon Carbide Bricks

- Factory Supply refractory Brick Anti Corrosion and High Thermal Conductivity Alumina Silicon Carbide Carbon Bricks

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Refractory Material > Special Refractory Material

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Cindy Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Cindy Tan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile