Home > Products > Wear Parts > High Wear Overlay

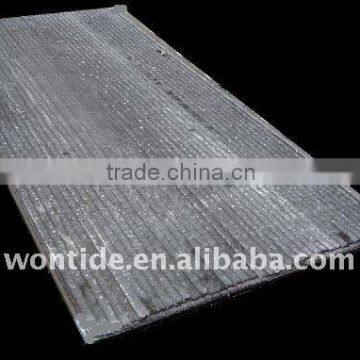

High Wear Overlay

- 100 Ton / Tons per Month

- Qingdao

- T/T

You May Like

Product Details

| Place of Origin | Shandong, China | Brand Name | WTD | |

| Model Number | WTD-WP |

Product Description

WTD Wear Plates present a very cost effective method of extending wear life within the conveyor system including; chutes, hoppers, bins, impact walls and screen plates.

Our wear plates adopts the latest plasma cladding technical.

Plasma Cladding is the latest modification of the surface after laser cladding technology .The technology derive the laser cladding and butt weld technology advanced, reject the surfacing and laser cladding shortage.The basic principle is: In the high temperature plasma beam, heating the alloy powder and the workpiece of the substrate surface with the rapid melting, mixing, diffusion, reaction, solidification,after the departure of the plasma beam from the laser cooling,leaving a high hardness wear-resistant layer in the surface,to achieve the strenthening and hardening the surface,to enhance the wear resistance of the workpiece.The layer of plasma cladding not only has high hardness,but also the bonding of the wear resistant and the workpiece substrate will not fall off under impact..This technology won the 2008 National Science and Technology Progress Award and a number of patents.

Techniacl Features:

1, The surface’s corrosion and oil can not cleaning and can direct metallurgical bonding of plasma cladding of high wear and corrosion of metal ceramic coating,so it doesn’t produce pollution,low cost and high efficiency..

2, Between the alloy layer and the workpiece are metallurgical,so it combined with high strength,not shedding.

3, Plamsa cladding layer thickness of pure alloy or metal-ceramic layer,while the cladding layer for a large number of hot metal alloy diluted uneven,so the appearance and quality are not as good as plasma cladding.

4, A significant improvement is in the operating enviroment,eliminating the harmful gases released during welding hazards to the workers,significantly reduced labor intensity,and production increased by 10 times more efficient than welding,reduce energy consumption by 20 %.

Meanwhile we can provide plasma cladding wear-resisting processing equipment.

The equipment can obtained at the surface of metal parts with high wear and corrosion metallurgy cladding layer, to enhance the parts wear resistance corrosion resistance, greatly increase the parts service life. The numerical control equipment is specially suitable for large steel cladding component, has the stable operation, strong anti-jamming capability, automation degree and high efficiency, the cladding quality is good wait for a characteristic, suitable for large area promotion.

The Features of the Equipment:

1, Arc starting reliable, accurate, and controllable cladding arc starting arcing synchronized to feed powder and broken powder function.

2, Cladding process control system can extinguish arc automatic cut off power supply and stop wo feed powder send spirit.

3, Using advanced and reliable numerical control technology,and the program settings,cladding process automatically.

4, Plasma torch steady continuous for cladding and melt shoot molding operation.

5, High production efficiency, suitable for large-scale industrial production

6, Thermal convension efficiency,low energy consumption.

Mold Project | WTD-2T plasma cladding wear-resisting processing equipment |

Power Source | Plasma power inverter |

Input power supply voltage | 380±10% |

Rated input capacity | 30KVA |

Rated load last rate | 100%(20°C) |

Rated cladding current | 300A |

Small arc rated current | 35A |

Load voltage | 150V |

Working voltage | 50V |

Cladding speed adjustment range | 0~1000mm/min |

Stroke | 1700×1000mm |

Argon gas consumption | 2m3/h |

Dimension | 2600×1800×2700mm |

Weight | Around 3 tons |

Contact Us

- Qingdao Wontide Co., Ltd.

- Contact nameAndy Liu Chat Now

- Phone86-532-80790581, 86-1866981578

- AddressB-8C,Jinfu Mansion,No.22 Shandong Road, Qingdao, Shandong

Product Categories

| Casting & Forging | Excavator & Bulldozer Parts | Material Handling | New Products |

| Oilfield Equipment | PM & MIM | Stamping,Welding,Assembly | Valves and Pipe Fittings |

| Wear Parts |

New Products

-

Aluminum Extrusion Products

-

6.5 HP Gasoline Sweeper Pertol Engine

-

Rotary Cultivator

-

Rotary Cultivator

-

Gasoline Sweeper

-

16in Steel Skidding Tongs

-

20in Steel Skidding Tongs

-

25in Steel Skidding Tongs

-

32in Steel Skidding Tongs

-

16in Swivel Grab Skidding Tongs

-

20in Swivel Grab Skidding Tongs

-

25in Swivel Grab Skidding Tongs

Popular Searches

- Air Cleaner Parts

- Diesel Engine Spare Part

- piston ring

- cummins parts

- Water Pump Assembly

- Oil Cooler Assembly

- Engine Components

- Cylinder Head Gasket

- Diesel Engine Part

- gasket kit

- Valve Cover Gasket

- Oil Drain Plug Gasket

- Hydraulic Motor

- power unit

- genuine cummins

- Cylinder Liner

- c18

- Main Bearing

- cylinder liners

- Rear Idler

- high pressure oil pipe

- high pressure pipe

- engine gasket kit

- automobile brush

- engine fan

- Hose Clip Clamp

- centrifugal clutch

- concrete mixer motor

- Engine Parts Gear

- fan assembly

Recommended Products

- ring gear

- Kelly Bar Rotary Drilling Rig Equipment Parts Interlock Friction Soilmec Type Kelly Bar

- Piling Rig Foundation Drilling Tools Telescopic Kelly Bars/ Interlocking kelly bar

- Hot Sell Foundation Friction Kelly Bar and Interlocking Kelly Bar

- Rotary Rig Drilling Spare Parts Building Material Interlocking Kelly Bar

- Hot Sell Kelly Bar interlocking kelly bar for Construction Borehole Rotary Drilling Rig

- Drilling Equipment Spare Parts, Inter-locking Kelly Bar for Rotary Drilling Rig

- Rotary Drilling Rig Construction Machinery Part Interlocking Kelly Bar

- Customize All Brand Drilling Rotary Rig Spring for Kelly Bar

- China Rotary Drilling Interlock Kelly Inter-Locking Kelly Bar for Rotary Drilling

- Locking Kelly Bar of Rotary Drilling Rig for Building Construction Pile Foundation Engineering Interlocking Kelly Bar / Frictional Kelly Bar

- Customizable All-Brand Multi-Lock Kelly Bar of New Condition Rotary Drilling Rig Equipment Accessory

Find Similar Products By Category

- Manufacturing & Processing Machinery > Engineering & Construction Machinery > Engineering & Construction Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Andy Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Andy Liu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile