Home > Products > Wood Plastic Profile,Panel and Sheet Machinery > carved PS Foam plastic photo frame maker

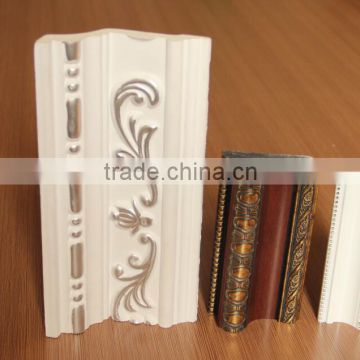

carved PS Foam plastic photo frame maker

- Qingdao

- T/T

You May Like

Product Details

| Condition | New | Application | Profile | |

| Plastic Processed | Other, PP PE PVC | Screw Design | Single-screw | |

| Automatic Grade | full auto | Place of Origin | Shandong, China | |

| Brand Name | Tongjia | Model Number | JG-MSC80/156 | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Screw

Material 38CrMoAl superior alloy steel nitriding treatment

Screw dia. Φ51/105mm

Quantity 2 pieces

Gearing type conical gearing

Barrel

Material 38CrMoAl superior alloy steel nitriding treatment

Depth of nitration 0.5-0.7mm

Hardness of nitriding HV940-1100

Roughness of surface 0.8µm

Transmission deceleration system

Main extruder driving motor 15KW

Motor type AC motor

Motor speed adjusting type by transducer

Fix quantity material supplying system

Material supplying method by screw

Screw rotary speed 0-45r/min

Motor power 0.75KW

Exhaust system

Vacuum pump type water cycle vacuum pump

Motor power 1.5KW

Vacuum degree 0-0.075MPa

PS Foaming Decoration Profile Application

Polystyrene foam decoration profiles can make Polystyrene Foamed Skirting Profile, Polystyrene Foamed Picture Frame, Mirro Frame, and others interior decoration which can replace the tradition wooden frame profiles, the costs are much lower and the quality is much better than wooden profiles.

Our company has developed over 180 new products machinery with 9 kinds, all of our products has passed CE Certificate from TUV. Many of our products have exported to Russia, Belarus, Iran, Singapore, Vietnam, Malaysia, Spain, Argentina,Brazil, more than 60 countries in the world.

Why choose us:

1. We are market-leader in this line in China. Our factory was founded in 1953 inplastic fields.

2. We have been engaged in the machine field for more than 20 years and have much experience in manufacturing plastic machines.

3. Brand-name parts of the machine.

4. Engineering team provide you with the most suitable model towards your products.

5. Technical training and service is the advantage of us.

6. The machine can working more than 10 years without damange by human.

7. We will reply your inquiry within 6 hours.

If you are interested in the machine,please contact

Ms. April

Tel: 0086 187 6688 9100

;-)

Contact Us

- Shandong Tongjia Machinery Co., Ltd.

- Contact namesam zhang Chat Now

- Phone86-537-2279166, 2986622

- AddressNo. 96, 327 Country Road, National High-Tech Development Zone, Jining City, Shandong Province. China, Jining, Shandong

Product Categories

New Products

-

PVC Profile/Decorative Board Production Line

-

wood plastic cabinet panel production line

-

wood plasttic door panel machine

-

PVC ceiling machine (Hot sale!Famous brand !!!)

-

pvc ceiling panel production line

-

PVC Profile/Decorative Board Production Line

-

WPC door panel machine

-

WPC floor machine

-

pvc decorative board production line

-

Plastic Crusher

-

wood plastic flour mill

-

precision engraver

Popular Searches

- plastic extruder

- extrusion machine

- twin screw extruder

- aluminum tube production line

- Foam Board Equipment

- production line

- extruding machine

- Production Equipment

- extrusion line

- Belt Making Machinery

- Extruder Machine

- Pet Strap Making Machine

- Pet Belt Making Machine

- Bubble Film Making Machine

- Cable Manufacturing Equipment

- plastic extrusion

- plastic machinery

- extruding equipment

- wire extruder

- cable extruding line

- Cable Extruder Machine

- Cable Manufacturing Machine

- decorative line

- Extrusion Production Line

- Engineering Lab Equipment

- eps machinery

- cement production line

- pipe making machine

- pipe production line

- Board Making Machine

Recommended Products

- xps foam board production line

- HDPE Pipe Production Line

- Petrochemical Granulation Equipment Use Polyolefin Pelletizing Die Plate

- Spare Parts Pelletizing Knife Holder Used for Granulating Polymer

- Spare Parts for Fixing Pelletizer Knives Pelletizing Cutting Disc

- PP PE underwater granulation system use knife rotor

- Industrial Cutting Blade for Underwater Pelletizing Unit for Plastic Granules Manufacturing

- Intensive Heated Channel Die Plate for Producing PP PE Particles

- Underwater Pelletizing Unit Use Pelletizing Blade for Plastic Granules

- Pelletizing Die Plate for Underwater Polyethylene Pelletizing System Extruder

- Metal-ceramic Composit Pelletizer Knife for PP PE Plastic Granule Extruding

- Flexible Pelletizer Knife Holder for Underwater Cutting Plastic Granules Line Carrier for Pelletizer Knives

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Plastic Extruder

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sam zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

sam zhang

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile