Home > Products > Auxiliary Equipments > low price waste tire/tyre steel wire baler manufacturer

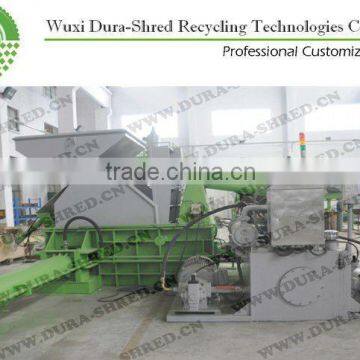

low price waste tire/tyre steel wire baler manufacturer

- 20 Set / Sets per Month

- shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Place of Origin | Jiangsu, China | Brand Name | dura-shred | |

| Model Number | steel wire baler | Type | Other, tire recycling line |

Product Description

Specifications

tire/tyre recycling line wire baler1.easy installation

2.Environment friendly

3.Low price,high profit

4.Low noise

This machine will densify large quantities of wire difficult to handle. Unparalleled briquette density, integrity and throughput provides a significant additional evenue stream for your tire recycling operation.

Tire Recycling line wire Baler to process materials including:

1.Tire Wire

2.Copper

3.Aluminium

4.Brass

5.Etc

Advantage:

Peak control

Our control system of the regulated pumps prevents the cost-intensive current peaks with the courses of motion.

Cost

Fewer energy costs by low connected load.

Filter

Two-way tank system with filter cleaning.

Efficient

Continuous work routine filling during the press process.

Cylinder protection

The length measuring system are integrated in the protects hydraulic cylinders.(disturbances by external sensors belong to the past)

Manufacturing

Internal manufacturing guarantees quality and rapid spare and wearing parts availability.

Service life

Small oil temperature by achievement-regulated pumps, higher service life of the hydraulic oil.

Tire Recycling Process:

Dura-Shred uses its experience and success to continually improve the design and manufacturing of our tire recycling systems to make them more effective and efficient throughout the reduction process. The reduction from whole tires to crumb rubber is accomplished through our:

1.Prime Shredder

Dura-Shred Dual Shaft Shredder 150: 150 hp rotating the blades, truck and car size tires are reduced to rough 3”shredded strips through the Prime Shredder. Rough shred is then recirculated until it can be sent to the Grater via a conveyer.

2.The Grater

Dura-Shred Grater 150: The Grater takes the chips and reduces them to 10mm-12mm. At this point 95%-97% of

the steel has been stripped and is removed with our magnet belt as the rubber mulch is transported

to the vibratory tables for separation. This will be the end of the mulch producing line. For crumb

rubber steel free mulch will be sent via conveyor to the Granulators for further processing.

3.Granulator

Dura-Shred Granulator: The G1 reduces the rubber down to a 5mm-7mm or 10-20 mesh, which is then removed

through a screening system. Additional steel and fiber are then removed through an air and vibratory

system before being sent to the surge bin for collection.

Scope of Project:

System is designed to produce the following byproducts: Steel, Fiber, Tire Derived Fuel Chips (TDF), Rubber

Mulch, Rubber Powder.

System Capacity:

Capacity for this system is 2.5 metric tons of input per hour.

Crumb Size:

10mm - 14mm Mulch (Can be removed after The Grater)

4mm-6mm and 10 / 20 mesh. (After the Granulators)

Crumb Rubber Purity:

95% Free of Textile.

95% Free of Steel.

95% Free of Stones and other contaminants.

Steel Purity:

92%-94% Contaminant free.

Power:

Power Type: 440V / 3Ph / 60Hz

Total Kilowatts: 607

Estimated Power Usage Per Hour of Operation: *** $65.56

***Based on a price of $018 per kilowatt hour.

Development space of market:

The method of recycling waste tyre is that separating the inner steel wire and fiber from waste tires through many kinds of technologies and grinding the rubber granules into powder.Waste tyre treatment equipment are suitable for international development and management style. It’s most advantage is it can recovery waste tyres to rubber granules/powder reaching to the availability 100%.

The rubber powder is widely used and almost covers all industrial fields. It can replace the material such as plastic and PVC, instead of nature rubber, be rebirth tires .It is used in sport runway and shoe soles; it also can be used to highway, air trip as well as third generation railway sleeper as modification asphalt.

Process:

Waste tyres- thick steel wire taking out——whole tyre cutting into large blocks(four or two pieces)—— rough shredding tyre blocks into pieces (50mm-100mm)——medium shredding into smaller ones(10mm-20mm)——fine shred into granules(3mm-4mm)——grind the granules into powder(20-100mesh)——magnetic separator for thin steel removing——fiber separator for rubber removing——packing

Rubber powder application:

1.Paving sport ground:

Runway, school sporting field, garden path, bowling alley, pavement, recreation field, basketball field, etc.

2.Automobile industry:

Train’s floor, disc silk ribbon for braking, soleplate of automobile and truck, shake sleeve, seal stripe, buffer, shock absorber, daily material for ocean shiping, tyres and inner unerlay of tyres, etc.

3.Architecture and equipment:

Adhensive/sealant, floors of hospital, company, insulated rubber material, carpet cushion, grass cushion for family animal, extruded products, module products, coating, bricks, thin slice, water-proof material, etc.

4.Application of geotechnical/asphalt

Drainage pipe, asphalt modified by rubber powder which can be used to construct highway and drivingway, filter, adjusting soil/coating layer for road surface, washing pipe with holes, runway for horse race, barrier for traffic or pavement, etc.

5.Regenerative rubber:

Rubber products manufacturing.

6.Other application

Proven Design and Technology.

A quality system with at an affordable price!

Fully Automated via 1 centrally located touch screen control panel.

Backed with one of the best Warrantees in the industry

Plz enquiry us freely,if you got any questions.

Contact Us

- Wuxi Dura-Shred Recycling Technologies Co., Ltd.

- Contact nameJason Wu Chat Now

- Phone0086-21-51719518, 62119986

- AddressWuxi City, Jiangsu Province, Wuxi, Jiangsu

Product Categories

New Products

-

Cloth Baler

-

Cloth Baler System

-

Cloth Baling Machine

-

Copper Baler

-

Hydraulic Vertical Baler

-

Automatic Baler

-

Automatic Baler System

-

Automatic Baling Machine

-

Baler Presser Equipment

-

Baler Pressing Equipment

-

Baling Press

-

Brass Baler Equipment

Popular Searches

- water treatment

- water purifier

- water filter

- water purification

- manganese water filter

- water iron remove

- water tank

- Water Treatment System

- drinking system

- Wastewater Treatment Equipment

- Industrial Equipment

- waste water treatment

- water filter system

- Sewage Treatment Equipment

- Water Treatment Equipment

- electric system

- wastewater treatment

- water plant

- Dewatering Machine

- oil treatment

- Multistage Centrifugal Blower

- water softener

- Chemical Dosing System

- hospital waste

- Waste Water Treatment Equipment

- Water Storage Tank

- uv sterilizer

- water filtration

- reverse osmosis

- ro system

Recommended Products

- High torque waste metal shredder waste metal breaker crusher

- Professional hard drive shredder-mini small shredder

- Wholesale Hotsale Pure Water Treatment Custom Size Coal Based Coconut Shell Granular Activated Carbon

- Wholesale Hotsale Pure Water Treatment Custom Size Coal Based Coconut Shell Granular Activated Carbon

- Hot Sale Manufacturer Wood Based Black Activated Carbon Coal Based Coconut Shell activated carbon In Water Treatment For Water

- Firemax Active Charcoal Powder Coal Based Adsorbent Absorption Treatment Particles of Coal-based Activated Carbon

- Gold Mine Activated Carbon Coconut Shell Based Activated Carbon for Gold Mining Industry Recovery Absorption Extraction Leaching

- Cost Effective Coconut Shell Activated Carbon for Gold Extraction Great Value for Your Investment

- Powdered Activated Carbon for Rapid Water Purification and Sewage Treatment with High Efficiency in Adsorbing Heavy Metals

- Cubic Activated Carbon Aquarium Filter Water Purification Honeycomb Activated Carbon

- Coconut Shell Activated Carbon Is Used to Remove Impurities From Water.

- Air Filters Activated Carbon 1 Ton Activated Carbon Price Pellets Powder Granular Activated Charcoal for Water Treatment

Find Similar Products By Category

- Industrial Equipment & Components > Environment Protection Device > Waste Treatment Equipment

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jason Wu

Hi there! Welcome to my shop. Let me know if you have any questions.

Jason Wu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile