Home > Products > Mould for Floor/Ceiling/Wall > Extrusion die for WPC pillar column

Extrusion die for WPC pillar column

- shanghai wuhan ningbo

- T/T Credit Card PayPal

You May Like

-

Extrusion die for WPC pillar column

-

Extrusion die for handrails

-

Extrusion die for cladding panel/extrusion molds for WPC exterior cladding panel/Plastic Wall Panels Extrusion Dies

-

WPC door lines door panle extrusion tool plastic dies and molds making in China Hubei

-

WPC keel extrusion mold/extrusion mould/WPC PVC keel moulding

-

Practical WPC PVC door frame extrusion mold/moulding door/frame moulding

Product Details

| Place of Origin | Hubei, China | Brand Name | Jinghua | |

| Model Number | W160x80 | Shaping Mode | Extrusion Mould | |

| Product Material | Steel | Product | Other, Plastic Extrusion Mould |

Product Description

Specifications

Extrusion die for wpc pillar1.special cooling design

fessional designers

3.high speed tooling output

4.CAD design

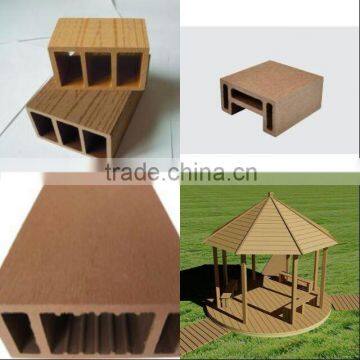

Extrusion die for WPC pillar

Our extrusion mould advantages:

1.we are founded in 2001, extend 13 years professional experennce gives us dominate position in extrusion moluld industry., quality and precision are the most import target of our company.our products enjoy an excellent reputation in plastic extrusion mould industry.

2.We owned a team of mature and experienced technicians,rich experiences skill workers from design, manufacture and debugging.

3.We can make all kinds of moulds according to customer requirement.The mould can be post-co extrusion, color co extrusion, embossing co extrusion, surface layer and so on.

4.Provide complete set of production process and technology transfer service

5. Flow channel systematic design is based on theoretical calculation, practical conclusion, adopting reasonable compressing ratio and stain technology according to different formula and technique

Die

- Designed by different formulations and melt flow characteristics

- Multi-cavity with material supplied to each cavity respectively,Smooth of flowing channel

- Integated mandrel structure, Mirror polishing

Calibrator

- High efficient and even cooling system

- A number of patented brightening technology

- The perfect combination of precise positioning and reliable shape

Water tank

- Spraying and immersing cooling system

- Vacuum and whirling water tank

- Floating tank plates, Find position automatically

Fine quality after-sale service:

1.We can provide a whole set of technical support including extruder election, formula process and extrusion mould.

2.supply . mold using instrusion, mold spare parts for you

3.we have excellent test mold technicians to test the mould

4.All the moulds must be inspected and tested to reach 100% qualified

before delivery.

Application:

Production line

Product test results

NO. | Test Items | Technical Requirements | Units | Measured Value | Single Conclusion |

1 | Extrusion speed | 0.8-1.8 | m/min | 0.87 | conform |

2 | Yield | >98 | % | 99 | conform |

3 | Thickness deviation | <1.2 | mm | 0.24 | conform |

4 | Water absorption | ≤3.0 | % | 1.0 | conform |

5 | Density | ≥0.85 | g/ cm³ | 1.38 | conform |

6 | Tightness | No leakage | / | conform | conform |

WPC Manufacture Steps:

Crushing waste plastic and some farm crops such as saw powder,stalk.flax,pole,cotton pole→raw material→mixed with plastic in high speed→pelleting(overlap) →extruded through extruder→die→alibrator and water tank→haul-off→cutter→finished products

Mould package:

Certificate:

Our company:

Website: www.jinghuamould.en.china.cn

Add: Machinery Industrial Park, Huangjinshan New Area ,Huangshi,Hubei,China mainland

Tel: +86-714-6399869

Hubei Province Wuhan tianhe airport:90 Minutes by car to pur company

If you are interested in our moulds, please feel free to contact with us and show us your sample picture or drawings.We will do our best to provide you with competitive price and professional service!

Contact Us

- Huangshi Jinghua Plastic Mould Co., Ltd.

- Contact nameCindy Shen Chat Now

- Phone86-714-6399869

- AddressMachinery industrial park,Huangjinsan New area, Huangshi, Hubei

Product Categories

New Products

-

WPC foam board extrusion mold/Wood and plastic cladding board mould

-

WPC decorate panel extrusion tool/wpc tool/plastic working tool/plastic molding tool/plastic decorative door moulding

-

decorative 3d wall panel moulding/wood moulding tools/molding of plastic/decorative frame moulding/decorative door moldings

-

PVC foam profile mould / polystyrene foam moulding / foam mould

-

WPC keel extrusion mold

-

BEST QUALITY EXTRUSION MOULD FOR WPC PANEL

-

PVC shutter extrusion mould

-

mold tool/embossing heat tool/plastic working tool/plastic cable tie tool/handrail tool/shape tool/wpc tool/plastic molding tool

-

extrusion shape/side moulding/plastic moulding frame/pvc moulding decoration/plastic moulding profile/decorative plastic molding

-

molding door/extrusion t-die/plastic extrusions window pvc/mould pvc/moulding door in Hubei

-

wpc mould for guardrails/wpc door frame moulding/wpc window frame moulding/pvc door frame moulding/pvc window frame moulding

-

WPC decking panel mould/moulds plastic/plastic mold maker/plastic mould manufacturer/plastic moulding mould

-

door lines extrusion tool/plastic mold maker/plastic mould die makers/door panel frame mould (Hubei)

-

WPC outdoor floor panel extrusion mold/WPC extrusion mould for hollow decking floor/PVC skirting board extrusion mould/PVC mould

-

WPC wall mold/wall decorative moulded panels/mould maker

-

WPC mould for the door/floor/ceiling/wall panel

-

High Quality PVC Panel Mould For Hollow Panel

-

extrusion mold for pvc hollow panel/pvc extrusion mold/extrusion mould

-

Hubei WPC Hollow Panel Mould For Decking Floor

-

flooring decking mould/wpc solid board mould/hollow panel mould

-

Good Price PVC Panel Mould For Hollow Panel in Hubei

-

PVC hollow panel decking board extrusion mould

-

PVC hollow panel board extrusion mould

-

wpc door panel mold/mold for hollow panel board/wpc mold for panel

Popular Searches

- plastic mould

- Pc Abs

- Pp Pvc Hdpe Abs

- 3d design

- document

- Agricultural Plastic Products

- plastic injection

- injection moulding

- injection mold

- Plastic Injection Part

- Appliance Part

- injection mould

- extrusion die

- computer plastic mould

- home automation

- Plastic Injection Mould

- Mould Design

- rubber mold

- Automotive Plastic Products

- Molded Product

- Plastic Injection Molding Product

- Injection Moulding Product

- Moulded Product

- Injection Mould Bumper

- Injection Molding

- Household Products Part

- cycle component

- Mould Maker

- rubber flap

- bumper mold

Recommended Products

- China Injection tooling maker for plastic mould manufacture factory

- high quality Bainuo EPP foaming mould EPP foam machines for package box automotive parts

- high quality Bainuo EPP foaming mould EPP foam machines for package box autopart

- high quality Bainuo EPS foaming mould EPS foam machines for package box

- Electronic Case Mold

- Electrical Appliances Plastic Cover Mold

- 2K Injection Molding Tooling

- Die Casting Parts Mold

- Automotive Lenses Mold

- China plastic injection mould factory for Europe export usage

- epoxy resin cast mould transformer insulator manufacture APG process chinese manufacture

- Epoxy Resin Injection APG Moulding die casting mold

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Cindy Shen

Hi there! Welcome to my shop. Let me know if you have any questions.

Cindy Shen

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile