Home > Products > Mine separator equipment > Grinding mill with wheels of China leading brand and Can be tailored

Grinding mill with wheels of China leading brand and Can be tailored

- Qingdao/Shanghai/Guangzhou/Shenzhen/Tianjin

- T/T D/P D/A Credit Card PayPal

You May Like

-

Wet wheel mill for gold of best performance and the newest type

-

Gold mining ball mill of Top brand and the newest type

-

Gold ball mill of Solid construction and China famous brand

-

Gold mill of various types for choosing and CE approved

-

Wet grinding gold machine of best price and quality guarantee

-

Save time dumpling molding machine

Product Details

| Condition | New | Type | Ball Mill | |

| Motor Type | AC Motor | Power(W) | 7500-25000 | |

| Capacity(t/h) | 100 | Place of Origin | Henan, China | |

| Brand Name | Dongfang | Model Number | NJ-1400 | |

| Dimension(L*W*H) | 1400*250*300mm | Weight | 14.5t | |

| Certification | ISO9001CE | Warranty | within 1 year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Grinding mill with wheels of China leading brand and Can be tailored

Our factory is nearly the toppest in the line of machiney manufacture industry, we have so many years experience that our technology is quite advanced and all of our engineers are professional. we have many types for each kind machine to choose.We also can tailor for you according to your extra requirements.o(∩_∩)o

Introduction :

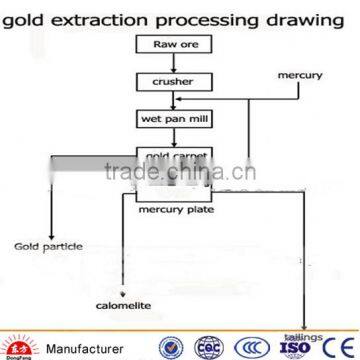

Grinding mill with wheels is also called wet pan mill .The grinding mill with wheels is mainly used for separate gold, silver, lead, zinc, iron,

molybdenum, cooper, antinomy and so on.

Grinding Mill With Wheels Specification:

Grinding mill with wheels is made of restructuring on the basis of conventional machine, For

the traditional machines, the workpiece is large and short lifetime, electrical power large,

installation cycle is long, the user can not immediately put into production, maintenance

and replacement of materials need for large lifting equipment .

The reason you choose us:

This machine is newly researched and developed,and it is absolutely compared with others.With less investment, fast efficiency, small floor space, saving power, sturdiness

and durability, easy maintenance and high return on investment. It is the most suitable

production for alternative ball mill, is ideal for small and medium enterprises dressing.Most importantly,this machine is our new type,as it can provide you higher efficiency and quicker return . It is praised by users because of it has the features of low investment, high production capacity,

low consumption, good efficiency, easy installation and maintenance. It is an excellent

equipment ,which can replace ball mill. It is a perfect equipment for medium

sized and small enterprises.

What's more ,we have professional installation:we has a professional installation team; they are hardworking, industriously

studying and brave in innovating. So far, they have successfully finished installation and commissioning

tasks for thousands of large and small projects. Besides, our installation team also helps our customers

train the operations staff, till they can operate the machinery independently.

Main technical parameters of grinding mill with wheels:

Model | Specification | Input size(mm) | Rotate Speed (r/min) | Powder(kw) | Weight(t) |

1600A | 1600×400×200×500±20mm | 30mm | 20-22 | 25KW | 14.5 |

1500A | 1500×350×200×460±20mm | 20-22 | 22KW | 13.5 | |

1500B | 1500×350×150×460±20mm | 20-22 | 22KW | 12.3 | |

1500C | 1500×300×150×420±20mm | 20-22 | 22KW | 11.3 | |

1400A | 1400×250×150×350±20mm | 16-18 | 18.5kw | 8.5 | |

1400B | 1400×250×150×350±20mm | 21-23 | 18.5kw | 8.5 | |

1350A | 1350×250×150×350±20mm | 16-18 | 18.5kw | 8 | |

1350B | 1350×250×150×350±20mm | 21-23 | 18.5kw | 8 | |

1300A | 1300×250×150×350±20mm | 16-18 | 15kw | 7.5 | |

1300B | 1300×250×150×350±20mm | 21-23 | 15kw | 7.5 | |

1200A | 1200×200×80×250±20mm | 17-19 | 7.5kw | 5.5 | |

1200B | 1200×200×80×250±20mm | 23-25 | 7.5kw | 5.5 | |

1100A | 1100×200×80×250±20mm | 17-19 | 7.5kw | 5 | |

1100B | 1100×200×80×250±20mm | 23-25 | 7.5kw | 5 | |

1000 | 1000×200×80×250±20mm | 13-15 | 5.5kw | 4.5 |

Delivering Pictures Presention:

Delivering goods to Indonesia

The operation and maintenance:

üThe raw material should be put into the machine after the machine running normally.üThis machine is not allowed to state with the material in the machine. If the machine is stopped because of stoppage, the residual material in the machine should be cleared. Then start the machine again.

üThe material should be put into the machine uniformity, not sometimes much sometimes less. It's better to use a feeding equipment.

üThe bearing part should be add butter regularly.

üEvery bolts should be checked to avoid flexible.

üThe bearing should be changed in time if it is damaged to avoid damage other parts.

üWhile the machine is running formally, you should check if there is abnormal sound in the reducer box and or bearing part, if there is a too high temperatureor excessive motor currentt and so on. If it happened, you should stop the machine to remedy of the trouble.

üIn consideration of your safety,the motor V-belt should be removed while youexamine and repair the machine.

About Our Company:

Henan Dongfang Group is a manufacture factory.The factory has very rich experience as it has a history of more than ten years. The factory covers more than 60,000 square meters,180 sets of gold processing equipment,more than 1,000 employees,and our factory .

This is our factory,Dongfang Group,and the workshop.You're welcome to visit our factory.

Contract Us:

If you want to know more about us and our production,please contract us,and we'll be very glad.

HENAN DONGFANG MACHINERY Co., Ltd.

Contact: Helen Zhao

Skype: dfmachine01

Tel: 0086-371-67668877 / 67944555

Fax: 0086-371-67944555

If you have any problems. Please feel free to contact us.

You're warmly welcome to visit our factory

Our website: http://hndongfang.en.china.cn/

Contact Us

- Henan Dongfang Machinery Co., Ltd.

- Contact nameDongfang China Chat Now

- Phone0086-371-67944555

- AddressNo. 18, Tongxing Street, Mazhai Economic Development Zone, Erqi Dist., Zhengzhou, Henan

Product Categories

New Products

-

Professional dumpling moulding machine from China

-

Professional machine for dumplings from China

-

Professional dumpling machine manufacturer from China

-

Hot sell in restaurant china dumplings machine

-

Hot sell in restaurant dumpling processing machine

-

Hot sell manual machine for making dumplings/dumpling making machine

-

Hot sell manual hand dumpling machine

-

Hot sell manual steamed dumpling machine

-

Hot sell manual household dumpling machine

-

Hot sell in restaurant meat dumplings machine

-

Hot sell in restaurant mini pierogi dumpling machine

-

Hot sell in restaurant mini dumpling machine

-

Household dumpling making machines good quality

-

Hot selling small dumpling machine

-

China manual dumpling machine

-

2015 automatic pierogi dumplings machine

-

2015 Hot selling in Australia make dumplings machine

-

2014 automatic chinese dumpling forming machines

-

High quality chinese dumpling machine hot selling

-

Chinese delicious food low dumpling making machine price

-

Chinese food home automatic dumpling maker machine

-

Chinese food home dumpling making machine

-

2014 automatic small dumpling making machine

-

2014 stainless steel automatic dumpling making machine from China

Popular Searches

- Graphite Material Powder

- Graphite Carbon Expandable Powder

- Petroleum Coke Cpc

- copper graphite

- Pet Coke Recarburizer

- high purity graphite powder

- Carbon Flake Graphite

- Coating Graphite

- Refractory Use Graphite

- Gray Powder

- thermal graphite

- Sheet Graphite

- Anthracite Carburizer

- Sulfur Gpc Graphite

- Carbon Powder Graphite

- natural costing

- crucibles graphite

- Expandable Packing Graphite

- disc bowl

- Carbon Graphite Additive

- Powder Cpc

- Anode Powder

- Additives Graphite

- all mill

- an mill

- at mill

- a d grind

- ball coal

- ball line

- be mill

Recommended Products

- CRLM1300 Vertical Roller Mill, Cement Slag Grinding Equipment, High-Efficiency and Energy-Saving Vertical Mill Production Line, Factory Direct

- Mingyuan ball mill/ slag ball mill for steel slag grinding recycling plant, slag grinding and recycling plant

- CRLM1300 Vertical Roller Mill

- Yosion Technology YXRM-5A-1850 Bottle Roller; Rod Mill;Fine grinding samples

- Sand Making Machine

- CRONUS Ring Roller Mill Industrial Grade Powder Processing Equipment

- Raymond Mill YGM/CLGM Series Calcium Carbonate/Talc/Gypsum Ultrafine Grinding Machine Industrial Grade

- Energy-saving and environmentally friendly Raymond Mill YGM/CLGM Series Calcium Carbonate/Talc/Gypsum Ultrafine Grinding Machine Industrial Grade

- CRONUS New Environmentally Friendly Ring Roller Mill Industrial Grade Powder Processing Equipment

- 【CRONUS Brand】Large ring roller mill Ore crusher Industrial grinding equipment

- CRONUS High-efficiency Energy-saving Ring Roller Mill Calcium Carbonate/Quartz Stone Special Ultrafine Powder Processing Equipment

- Factory direct supply CRONUS Ring Roller Mill 200-3000 mesh crusher non-metallic mineral grinding machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mining Machinery > Mining Mill

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Dongfang China

Hi there! Welcome to my shop. Let me know if you have any questions.

Dongfang China

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile