Home > Products > SMT Consumption/Tools > Soldering Station Hakko 936

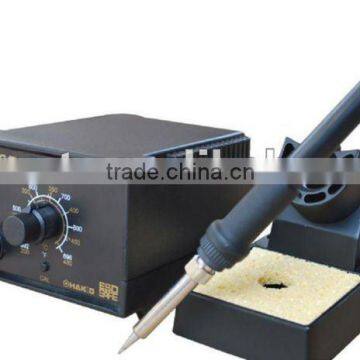

Soldering Station Hakko 936

- Shenzhen

- T/T Credit Card PayPal

You May Like

Product Details

| Place of Origin | Guangdong, China | Brand Name | Hakko | |

| Model Number | 936 |

Product Description

Specifications

1.Brand: Hakko2.Model:936

3.Antistatic

4.Output Voltage:24V AC

5.Dimensions:120(W) x 93(H) x 70(D)mm

HAKKO 936 Soldering Station

Specification

Name | HAKKO 936 |

Power Consumption | 100, 110, 220-240V / 60W, 120V / 65W |

Part list

Names of parts

Soldering Iron

900S 900S-ESD | 907 907-ESD | 908 908-ESD | |

Power Consumption | 24V AC-50W | ||

Tip to Ground Resistance | Under 2ohm | ||

Tip to Ground Potential | Under 2Mv (TYP 0.6Mv) | ||

Heating Element | Ceramic heater | ||

Cord Assembly | 12.m (4ft) | ||

Total Length(w/o Cord) | 176mm (7in) | 190mm (7.5in) | 200mm (7.9in) |

Weight (w/o Cord) | 25g (0.06Ibs) | 44g (0.09 Ibs) | 54g (0.12Ibs) |

Station

936 Station / 936 Station ESD | |

Output Voltage | 24V AC |

Temperature Rang | 200 – 480°C / 392 – 896°F |

Dimensions | 120(W) x 93(H) x 70(D)mm |

4.7(W) x 3.7(H) X 6.7(D)in | |

Weight (W/O Cord) | 1.300g (2.9Ibs) |

Maintenance

1. Set the temperature to 250°C(482°F)

2. When the temperature stabilizes, clean the tip with the cleaning sponge and check the condition of the tip.

3. If there is black oxide on the solder plated portion of the tip, apply new solder (containing flux) and wipe the tip on the cleaning sponge. Repeat until the oxide is completely removed. Coat with new solder.

4. If the tip is deformed or heavily eroded, replace it with a new one

Calibrating the Iron Temperature

1. Connect the cord assembly plug to the receptacle on the station

2. Set the temperature control knob to 400°C(750°F)

3. Turn the power switch to “ON” and wait until the temperature stabilizes. Remove the CAL potentiometer plug.

4. When the temperature stabilizes, use a straight-edge screwdriver or small plus (+) screwdriver to adjust the screw (marked CAL at the station) until the tip thermometer indicates a temperature of 400°C(750°F). Turn the screw clockwise to increase the temperature and counterclockwise to reduce the temperature. Replace the CAL pot plug.

More picture on HAKKO Tools

Contact Us

- Shenzhen Gosmt Technology Co., Ltd.

- Contact nameRago Cheng Chat Now

- Phone86-0755-33939603

- AddressRoom 2B3 Chuangjian Building Road 2 Qianjing Bao An Shenzhen China, Shenzhen, Guangdong

Product Categories

New Products

-

HAKKO 936 SMT Solder Machine

-

SMT Solder Machine Hakko FX-950

-

HAKKO Soldering Tips T12-1402

-

Desktop Magnifier lamp

-

Desktop Magnifier lamp

-

Desktop Magnifier lamp

-

Stereo Zoom Microscope Portable Type

-

Stereo Zoom Microscope

-

Stereo Zoom Microscope Magnification 7X-45X

-

Magnifying lamp

-

HAKKO Smoke Absorber

-

SMT Splice Clip

Popular Searches

- welding positioner

- weld magnet

- turning rotator

- rotator

- nickel base powder

- bga reballing

- auto gas igniter

- bga repair system

- nozzle spray tip

- digital paper collating machine

- carbide spraying powder

- infrared bga rework station

- ir bga rework station

- acetylene flashback arrestor

- pnme cutting nozzle

- reballing solder ball

- ceramic welding backing

- welding ceramic backing

- welding rotary table

- welding turning table

- turntable positioner

- welding table positioner

- pipe joint sleeve

- magnetic welding clamp

- chuck welding positioner

- gas lens

- welding revolving table

- flashback arrestor for torch

- flashback arrestor for regulator

- pipe welding rotator

Recommended Products

- MECHANIC OT Series Fast-Heating Soldering Tips for Precision Electronics Repair

- Phosphor Bronze Seamless Bellow/Hydroformed Bellow

- Hydrofoamed Seamless Stainless Steel Bellow/Contact Retainer for Vacuum Interrupter

- Silver Copper Brazing Washer/Silvaloy721/721 VTG

- Steel Turned Aluminum Brass Precision Hardware?CNC?Machining Machine Milling Part Parts

- Custom High CNC Machining Parts Stainless Steel Metal Working Process Trustable Manufacturer

- CNC Machining, Mechanical Parts,OEM Custom CNC Machining Spare Parts Alloy Aluminum Die Casting Process Working Medium Air

- CNC Machining, Mechanical Parts, Lathe Processing Services, Milling Parts

- Custom CNC Aluminum and Metal Machining Services for OEM ODM

- Stainless Steel Carbon Parts CNC Turning Machining Services Shop

- 5 Axis Custom Aluminum Brass Steel Metal CNC Lathe Turning Milling Protype Part Product Manufacturing Center Machining Service

- Aluminum Metal Processing Machinery Parts Stainless Steel Milling 4 Axis CNC Machining

Find Similar Products By Category

- Industrial Equipment & Components > Welding & Soldering Supplies > Other Welding & Soldering Supplies

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Rago Cheng

Hi there! Welcome to my shop. Let me know if you have any questions.

Rago Cheng

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile