Home > Products > product making machines > plastic panit bucket making machines

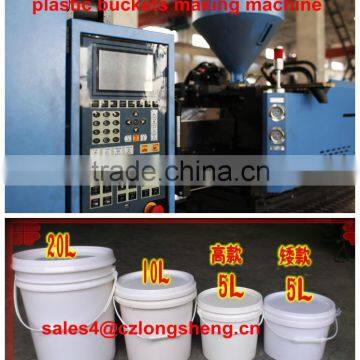

plastic panit bucket making machines

- Shanghai

- T/T L/C D/P D/A Credit Card PayPal

You May Like

Product Details

| Condition | New | Type | Preform Injection | |

| Style | Horizontal | Brand Name | LONGSHENG | |

| Model Number | LSF-528 | Place of Origin | Jiangsu, China | |

| Plastic Type | Thermoplastic | Automatic | Yes | |

| Injection Weight | 2167gr | Injection Rate | 456-514g/s | |

| Clamping Force | 5280KN | Opening Stroke | 800mm | |

| Power(W) | 38kw | Certification | ISO9001,SGS,CE | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Nude package

Product Description

Plastic bucket making machines we build from 2580KN to 8800KN,suitable for different sizes of bucket production requirements.

All machines adopt advanced German technology and Equiped with servo motor, which energy saving by 60% in average ,with longer working life (low oil temperature),low noise ,high precision (close looped system ).

We always try our best to cooperative with every customer and satisfy you well with competitive prices.

Engineers are available to service machinery overseas.

Technical specification of machines;

| Model No | Clamp force (KN) | Injection weight (g) | Tie bar sizes (mm) | Toggle stroke (mm) | Mold sizes (mm) |

| LSF-68 | 680 | 60-107 | 310*310 | 285 | 100-330 |

| LSF-98 | 980 | 140-188 | 360*360 | 330 | 150-400 |

| LSF-128 | 1280 | 191-267 | 410*380 | 380 | 150-430 |

| LSF-148 | 1480 | 201-282 | 410*410 | 380 | 150-460 |

| LSF-168 | 1680 | 274-428 | 460*460 | 450 | 180-520 |

| LSF-208 | 2080 | 347-518 | 510*510 | 500 | 200-530 |

| LSF-258 | 2580 | 507-730 | 560*530 | 505 | 200-560 |

| LSF-308 | 3080 | 830-1136 | 630*630 | 590 | 200-630 |

| LSF-398 | 3980 | 1260-1646 | 720*720 | 700 | 280-760 |

| LSF-528 | 5280 | 1920-2430 | 810*810 | 800 | 350-850 |

| LSF-628 | 62800 | 2270-2903 | 880*835 | 840 | 330-880 |

| LSF-718 | 71800 | 2560-3826 | 910*910 | 930 | 380-950 |

| LSF-880 | 88000 | 4000-5525 | 1000*1000 | 1000 | 420-1120 |

| LSF-1180 | 11800 | 4203-5871 | 1150*1100 | 1200 | 500-1200 |

| LSF-1380 | 13800 | 5969-8125 | 1300*1260 | 1260 | 530-1280 |

| LSF-1680 | 16800 | 7520-10015 | 1500*1350 | 1520 | 700-1500 |

| LSF-2200 | 22000 | 11349 | 1650*1650 | 1650 | 800-1620 |

| LSF-2680 | 2680 | 23678 | 1800*1720 | 1720 | 800-1800 |

Clamping Unit:

1. Optimized Platen Design with high rigidity and enlarged space between tie bars

2. Euromap-based Platen Layout, locating design in moving platen to better suit various molds

3. New ejection system design with longer ejection stroke, bigger space and better rigidity

4. Hydraulic drivien gear-type mold height adjustion mechanism

5. Relocation of mechanical safety interlock for easier operation

6. linkage structure for front connecting rod increases connectingrod's strength greatly, as well as the whole clamping unit's rigidity & accuracy.

Injection Unit:

1. High Quality Linear Motion Guide ensure the smooth & accuracy of injection process

2. High Speed & Pressure injection structure can improve the injection speed

3. Twin nozzle cylinder ensures more even & stable structure

4. Specialized screw barrel design for various appliance

Hydraulic System:

1. The double proportional compound valve control system pressure & flow, highly sensitive & stable

2. Imported high quality Pump, low noise, long lifespan & stable in performance

3. World-famous servo hydraulic system optional, better performance in lower noise & energy saving

4. The precise feedback control of servo system to the pressure & flow, with higher sensitivity & more accurate repeatability precision

5. High performance hydraulic valve, less failure, fast switch, convenient maintenance

6. Low pressure mold protect system, which is more suitable for the precise mould

7. Greese & lubrication oil in dependent lubrication system can lubricate everywhere in the best situation

Electrical System:

1. Control by double CPU, the system HMI use X86 300MHz technical grade display. The system employees a RISC 140MHz microprofessor, with high speed, noise-immunity, fan-less and lower power consumption, independent control structure improve the stablity of control

2. Porcheson display screen , user friendly screen & optional choose of language

3. Equiped with USB(2.0) port & ethernet(100-base T) ports

4. 32 Points input & output, entendable and trouble spot can be replaced easily

5. 120 technological parameters access can be stored & uploaded with an ordinary USB drives

6. Injection End and temperature tracking is curve display, dynamic recorder parameter is modified, dynamic warningis exhibited, all these make the operation more convenient.

Servo Controller Part:

1. High Precise Control

The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is <0.3%

2. High sensitive response

Because the motor vector is matched with the controller accurately, it only takes 0.5sec. inputing the number from 0 to max. Compared with other traditional hydraulic injection molding machine, AF series is more faster in speed with shorter cycle time and high efficient in production

3. Energy Saving

Overall efficiency is 10% more & driving capacity is 18% more than common machine. This series can save 30-80% energy, and achieve first-class energy efficency.

24 hours technical support by email.

one year guarantee

Calling or door to door services

Company Profile

Changzhou Longsheng Machinery Co., Ltd. (Longsheng) is located at Zhonglou Science and Technology Industry Park of Changzhou. We mainly produce and sell plastic injection molding machines, with high technology and reliable quality. Our products are selling well all over the world. We compare price with the same quality, while comparing quality with the same price, and compare service with the same quality and price, so as to improve our management. We always integrate optimized designs with manufacture and good sales service together. We utilize 24 hours networking for sales services. All lifecycle services for products and smile are our characteristics. Ways to success start from Longsheng. With strong capability, Longsheng is devoted to building a brand name - Longsheng Machinery Series. The clamp force of our machines ranges from 600KN to 16800KN, and shot weight ranges from 63g to 10,000g. Our plastic injection molding machines are widely applied in the areas of automobile, mechanical, chemical, and electrical industries, daily supplies, and toys. With good quality, professional services and sincere credit, Longsheng can go along with new and old clients, to realize the complementary of each other's advantages, resource sharing and mutual benefits. We can try to create a prosperous future with our customers as we always do.

Contact Us

- Changzhou Longsheng Machinery Co., Ltd.

- Contact nameRichard Chan Chat Now

- Phone0086-519-88018962

- Address65-28#,Xinggang Road,Changzhou, Changzhou, Jiangsu

Product Categories

New Products

-

plastic injection for chair making

-

injection molding machine for gallon cap

-

all sizes plastic pallets making machine

-

Bimetal screw PVC injection molding machine

-

resin injection machine

-

Bimetal screw injection moulding machine for recycle materials

-

injection moulding machine for sale

-

pvc pipe plastic injection manufacturer

-

servo hydraulic injection moulding machine for plastic products

-

injection pipe fittins molding mold

-

plastic pallets making machine for loading good

-

100gr injection moulding machine for toys

Popular Searches

- plastic machine

- hydraulic bottle

- instruction

- sole pressing machine

- toe lasting machine

- shoe making machine

- injection molding machine

- plastic injection molding machine

- cap making machinery

- cap molding machine

- die clicker

- bottle cap making machine

- plastic cap making machine

- cap injection molding machine

- oil injection

- horizontal injection moulding machine

- small injection moulding machine

- injection moulding machine

- shoe-making machinery

- shoe machinery

- cap making machine

- slide tie

- injection machine

- shoe polisher

- shoe making equipment

- plastic injection machinery

- plastic injection mould machine

- plastic injection moulding machine

- horizontal injection molding machine

- preform injection molding machine

Find Similar Products By Category

- Manufacturing & Processing Machinery > Plastic Machinery > Injection Molding Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Richard Chan

Hi there! Welcome to my shop. Let me know if you have any questions.

Richard Chan

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile