Home > Products > Concrete Block Making Machine > brick mold machine,QT4-15 full automatic block machine

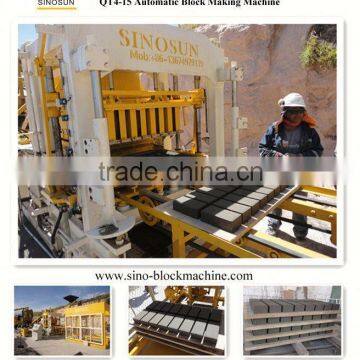

brick mold machine,QT4-15 full automatic block machine

- Qingdao

- T/T D/P D/A

You May Like

Product Details

| Condition | New | Type | Hollow Block Making Machine | |

| Brick Raw Material | Concrete | Processing | Brick Molding Machine | |

| Method | Hydraulic Pressure | Automatic | Yes | |

| Capacity | 390*190*190 mm 700~900 pcs/h | Place of Origin | Henan, China | |

| Brand Name | SINOSUN | Model Number | QT4-15 | |

| Voltage | 220V/380V-50HZ | Power | 27 KW | |

| Dimension(L*W*H) | 7100x1600x2610mm | Certification | ISO | |

| Warranty | 15 months | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

brick mold machine,QT4-15 full automatic block machine

Concrete Block machine, Cement Brick Machine, Hollow Brick Machine

(SINOSUN)

I. Company Brief Introduction

China Block/Brick Making Machine Manufacturer of Zhengzhou SINOSUN Machinery Co., Ltd., which is a leading and professional manufacturer and exporter, specialized in block making machines, brick plant, concrete machinery and some other construction machines in China, including brick machine, block making machine, automatic batching plant, cement silo, concrete mixers, conveyor belt, concrete block machine, mould, cement scale, elevator, forklift truck, block making machine production line, automatic production line, hydraulic brick pressing machine, etc.

II. Block Machine Introduction

1. Our concrete block making machine uses Germany Siemens PLC control system;

2. Uses high-dynamic proportional and directional valves, the automatic block machine could adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; uses integrated high-pressure and soft oil pipes, easy installation;

3. Integrated structure of vibrating and molding platforms, which reduces the weight of the machine, and improves the vibrating efficiency;

4. Uses damping blocks to reduce the vibrating force on the mechanical parts, improve the using lifetime of the machine, and reduce the noise;

5. Adopting four guide posts, makes sure the moulds up and down smoothly, in a level, no parallel, also makes sure the block made are smooth in surface, same thickness in every place;

6. Heavy-duty machine frame, which uses high-intensity steel and advanced heat treatment, is wear resistant;

7. Multi-functional, can make hollow blocks, solid bricks, paving blocks, tiles etc in different sizes. Wide material range, such as fly ash, slag, coal gangue, industrial waste, hold river sand, ceramsite, grain slag etc.

III. Capacity of our QT4-15 Block Making Machine:

IV. Components of Q4-15 Block Production Line:

QT4-15 Block Production Line | ||

No. | Components | Quantity |

1 | JS500 Mixer ( for concrete material ) | 1 set |

2 | B500x8m Belt Conveyor ( for concrete material ) | 1 set |

3 | QT4-15 Main Machine | 1 set |

4 | Pallet Feeder | 1 set |

5 | Green Block Conveyor | 1 set |

6 | Hydraulic Station | 1 set |

7 | PLC control | 1 set |

8 | Hollow Block Mould | 1 set |

9 | Pallet Stacker | 1 set |

10 | Trolley | 2 sets |

Optional Parts | ||

1 | Color Material Feeding Machine | 1 set |

350 Pan Mixer ( for color material ) | 1 set | |

B500x6m Belt Conveyor ( for color material ) | 1 set | |

2 | 50T Cement Silo | 1 set |

3 | Three-bin Aggregate Batcher | 1 set |

4 | Cement Screw Conveyor | 1 set |

V. Pictures of Brick Machine Production Workshop:

VI. Pictures of Customers Visiting our Brick Making Machine:

VII. Pictures of Block machine Installed in Foreign Countries:

VIII. Pictures of Concrete Block Machine Shipping:

IX. Quality Control (QC):

Third Control

ISO9001:2000 Certificate

European CE Certificate

Environment Protection Design

X. Commercial Terms:

Delivery Time : 25~30 Working Days

Payment Terms : 30% advanced payment by T/T, 70% balance payment before shipping by T/T, or L/C.

Transportation : by sea or railway in container.

XI. After Sales Service :

1. Hollow Brick machine Turn-Key Solutions

2. Erection & Commissioning Service

3. Operation Training Service

4. Spare Parts Supply ( all working life)

....

Contact Us

- Zhengzhou SINOSUN Machinery Co., Ltd.

- Contact nameSinosun Li Chat Now

- Phone86-371-89915650

- AddressNo. 2 East Block, Dongfeng Road East #18, Jinshui District, Zhengzhou, Henan

Product Categories

| Asphalt Mixing Plant | Asphalt releated equipment | Auxiliary Components | Burner |

| Concrete Block Making Machine | Concrete Mixing Plant | New Products |

New Products

-

hollow block casting machine Supplier QT8-15

-

QT5-15 low price fly ash brick making machine made in China

-

QT5-15 vibrated block making machine

-

QTF3-20 new technology color paving brick machine

-

small profitable machine small mobile brick making machine

-

Egg laying block making machine price,hydraform block making machine

-

concrete bricks machine equipment QT12-15

-

germany technology interlocking brick machine 2000~2400 pcs/hr

-

SINOSUN Construction hollow brick making machine

-

hydraulic press brick machine 700~900 pcs/hr

-

Effective mechanical block machine 700~900pcs/h

-

block making machine manufacturer (NEW TYPE)

-

high pressure block making machine QT12-15

-

retaining wall block machine QT4-15

-

cinder block making machine (1200~1440pcs/h)

-

block making machine in Mozambique

-

hydraform block making machine price QT8-15

-

mobile egg laying block making machine price QTY4-30

-

automatic cement brick making machine for sale QT8-15

-

machine made bricks 1000~1300 pcs/hr

-

SINOSUN QT10-15 full-automatic brick making machines

-

SINOSUN face brick making machine

-

Stationary Full-auto 1200~1440 pcs/hr compressed brick making machine

-

Multi-purpose (700~900pcs/h) polystyrene foam block machine

Popular Searches

- sand making machine

- sand making production line

- building model making

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- asphalt concrete mixer

- mobile asphalt mixer

- asphalt bitumen mixer

- asphalt mixer plant

- vehicle equipment

- paver

- making machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- asphalt drum plant bitumen

- double drum

- brick making machinery

- block machine

Recommended Products

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker with Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Sinosun Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Sinosun Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile