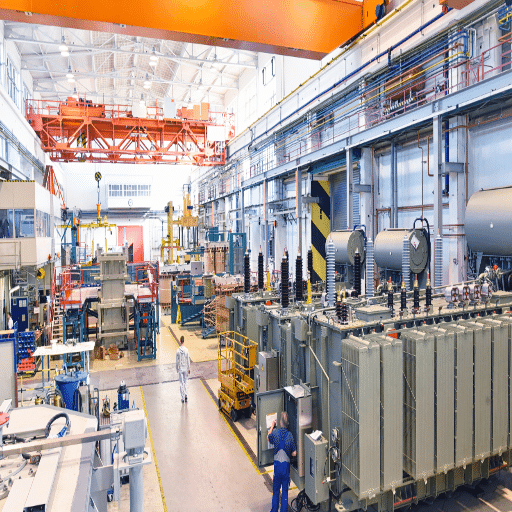

From aerospace to medical technology, precision engineering is the innovation hub that is evolving the entire industry landscape. It has fostered a unique subset of businesses that exhibits unrivaled industry concentration, unmatched reliability, and global benchmark offerings in quality and perfection. In this article, we explore the top 10 world-leading manufacturers in precision engineering. These are companies that not only pursue groundbreaking advancements but also continuously redefine and expand the realms of engineering possibilities for everyone. This list will benefit not only experts in the industry or technology geeks, but also anyone inquisitive about how the modern engineering wonders came into being. So, prepare to take a deeper look into the attributes of the organizations, which are redefining unparalleled perfection in one of the most vital niches of innovation.

1. Mazak Corporation

Founded: 1919

Introduction: A worldwide leader in intricate contracting and engineering, Mazak Corporation is meticulously headquartered in Japan. They are famous for their CNC machine tools and have always been at the forefront of providing fabrication technologies that enhance productivity and output quality throughput. They focus on advanced manufacturing processes to bolster their offerings and have committed extensive resources to R&D activities.

Main Products: Multi-tasking machines, laser cutting machines, CNC Turning machine centers, etc.

Key Advantages: Value for investment with precise accuracy, automation, and a firm hold in the global market.

Key Disadvantages: Smaller operations may find difficulty with premium model pricing.

Website: www.mazak.com

2. DMG MORI

Founded: 1948

Introduction: One of the biggest makers of state-of-the-art precision equipment in Germany, DMG MORI is also a forerunner in Japan. The company is notable for its constant innovation and commitment to Industry 4.0 technologies, ensuring a seamless integration of advanced digital manufacturing solutions.

Main Products: Automation solutions, CNC lathes and other advanced turning centers, vertical and horizontal grinding machines.

Key Advantages: Competitive after-market services, unmatched precision equipment, and sustainable production counselling.

Key Disadvantages: Users have experienced gaps in after-market services.

Website: www.dmgmori.com

3. Haas Automation, Inc.

Founded: 1983

Introduction: Based in the USA, Haas Automation is one of the continent’s leading builders of machine tools, equipped with the best facilities. They offer products and good quality services, including turning engines, coordinate precision machines, and vertical grinders.

The company continues to actively pursue innovation in Hoa’s CNC and their competitors’ technologies to increase the precision and reduce the costs of the CNC rotary table and five-axis machines. It heavily focuses on reducing the burden of complicated operations on the end user.

Main products: Rotation tables and 5-axis machines.

Key Advantages: Lower average manufacturing costs for rotary tables and five-axis CNC machining.

Key Disadvantages: Not enough branches to compete with other international manufacturers.

Website: www.haascnc.com

4. FANUC Corporation

Founded: 1956

Introduction: A widely recognized multinational company from Japan specializing in the automation of factories, robotics, and CNC technologies. Customers who seek reliable and cutting-edge products turn to FANUC as their go-to provider. Their systems are used globally to boost productivity in widely used manufacturing facilities, which is a testament to their dependability and innovation.

Main Products: CNC controllers, robotics systems, and servo motors.

Key Advantages: Robotics systems are known to be durable in the industry, and inaccurate servo motors have excellent precision.

Key Disadvantages: Complex systems tend to be too complicated, usually resulting in a long learning period.

Website: www.fanuc.co.jp

5. Okuma Corporation

Founded: 1898

Introduction: Based in Japan, Okuma Corporation is one of the oldest precision engineering companies. It has built a reputation for innovation and quality over more than a century. It is known for minimizing thermal deformation with its Thermo-Friendly Concept, which enhances machining accuracy.

Main Products: CNC lathes, grinding machines, milling machines, and multitasking machines.

Key Advantages: Advanced thermal stability, integrated control systems, and durability.

Key Disadvantages: The initial setup is expensive.

Website: www.okuma.com

6. Trumpf Group

Founded: 1923

Introduction: Germany-based Trumpf Group is a dominant player in the precision engineering industry, focusing on machine tools and industrial lasers. Their goal is to improve efficiency within industrial manufacturing by introducing new and innovative technologies aimed at streamlining processes with unmatched engineering skills.

Main Products: Laser cutting machines, punch laser machines, and 3D printing systems.

Key Advantages: Innovative laser technology, precision in the sheet metal processing, and ingenuity.

Key Disadvantages: Equipment and maintenance are expensive.

Website: www.trumpf.com

7. Makino Milling Machine Co.

Founded: 1937

Introduction: Makino is well known globally, and its innovative machining centers and automation solutions make it a top manufacturer in Japan. Customers in the aerospace and automotive industries that require high precision greatly value their products and services.

Main Products: Vertical and horizontal machining centers, EDM machines, and die/mold solutions.

Key Advantages: Relatively low downtime, high-end technology, excellent surface finish, and reliability.

Key Disadvantages: Relying on a single supplier or service provider can result in greater overall costs as pricing strategies become less competitive, steep competition, and a comparatively higher lag.

Website: www.makino.com

8. Hurco Companies, Inc.

Founded: 1968

Introduction: Hurco is an American manufacturer of CNC Machining Centers and other machine tool technologies. They specialize in providing efficient control systems that simplify precision engineering for greater ease and effectiveness in manufacturing. Focus Goes to Hurco’s focus vertical, which is small- and medium-scale machine shops.

Main Products: CNC Machining Centers, lathes, turning centers, and specialized proprietary software systems.

Key Advantages: Ease of use, effective software integration, value for money, and competitive pricing.

Key Disadvantages: Limited variety when compared to larger industry competitors.

Website: www.hurco.com

9. Mitsubishi Heavy Industries

Founded: 1870

Introduction: One of the largest multinational companies in Japan, Mitsubishi Heavy Industries, is globally recognized for groundbreaking technologies within precision engineering aimed at the aerospace, automotive, and energy sectors, alongside other industries. Providing reliable and high-precision manufacturing processes is their forte, thanks to extensive industry experience.

Main Products: Sells CNC systems, automated machinery, and high-technology industry components.

Key Advantages: Broad capabilities, higher than industry average technical support, and innovations.

Key Disadvantages: Focus on smaller-scale manufacturing projects is somewhat lacking.

Website: www.mhi.com

10. Yamazaki Mazak India

Founded: 1998 (India division of Mazak Corporation)

Introduction: Yamazaki Mazak India is a subsidiary of Mazak Corporation and focuses on servicing the needs of precision engineering in India.?Their parent organization’s standards are upheld while also addressing the needs of the regional market with advanced CNC machinery solutions.

Main Products: CNC machining centers, five-axis machines, and automation integrations.

Key Advantages: Local support, strong regional focus, and advanced technology.

Key Disadvantages: Lesser product diversity compared to global offerings.

Website: www.mazakindia.in

Frequently Asked Questions (FAQs)

1. What do precision engineering manufacturers specialize in?

Precision engineering manufacturers focus on producing parts with the highest accuracy in complex details, which are utilized in different fields such as aerospace, automotive, medicine, and electronics. They are known for advanced technologies such as CNC machining, 3D printing, and precision measurement tools that provide superior quality and tight dimensional tolerances.

2. What methods do precision engineering manufacturers use to uphold strict quality standards?

These manufacturers undergo strict quality control processes, which involve ISO 9001 or AS9100 certifications, regular audits, perpetual inspections, and rigorous tests. Other advanced tools, such as Coordinate Measuring Machines (CMM) and optical scanners, also help ensure the precision of the machined parts.

3. Who uses precision engineering?

Precision engineering is used in several industries: the aerospace industry manufactures engine components, the automotive industry manufactures gear systems, the medical industry makes surgical tools and implants, and the electronics industry makes micro-components for circuit boards and devices.

4. What is the influence of modern-day technology on precision engineering?

5-axis CNC machining, automation, and the incorporation of Artificial Intelligence are some of the modern advancements that are far more productive and helpful in decreasing human error and improving precision in manufacturing processes. Other smart manufacturing methods also allow for monitoring in real time and adaptive changes.

5. Why is a regional focus significant to precision engineering manufacturers?

Being regionally focused allows precision engineering manufacturers to offer and support customers with fast response times, tailored services, and regional mastery. This ensures that global benchmarks are met, along with quality and competitiveness for other countries in the region.

6. Are components that undergo precision engineering economical?

Precision-engineered components incur heightened costs due to employing sophisticated materials and rigorous machining processes. Nevertheless, their enhanced reliability, accuracy, and performance make them much more economical in the long run because of lower waste, reduced downtime, and a longer product life.